Single-component epoxy adhesive solution for impregnating glass fibers

An epoxy adhesive, one-component technology, used in epoxy resin adhesives, adhesives, fiber processing, etc., can solve problems such as low peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

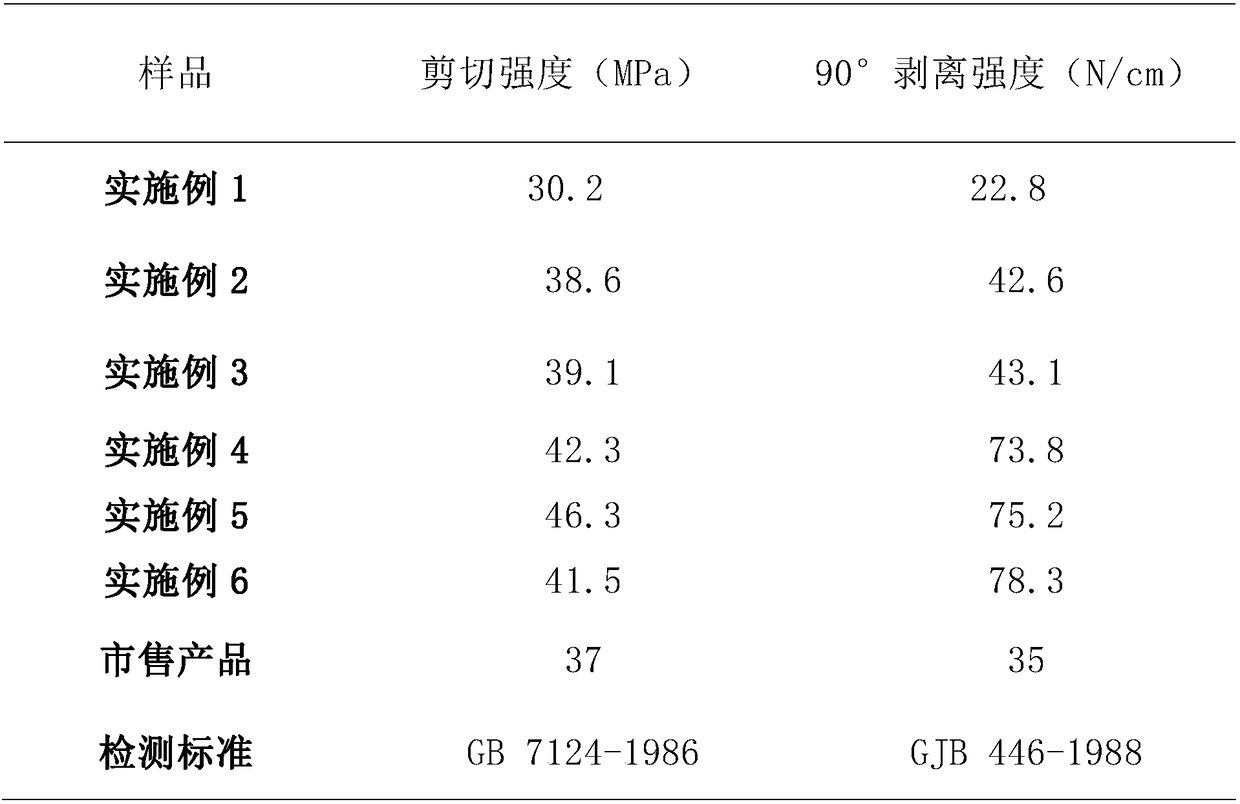

Examples

Embodiment 1

[0023] 1. Preparation of curing agent

[0024] Preliminarily mix the curing agent dicyandiamide, the accelerator and the epoxy resin according to the proportion, and grind it into a paste through a three-roll mill.

[0025] 2. Preparation of rubber

[0026] Weigh the raw materials with the following mass percentages, and fully vacuum stir the raw materials at a temperature of 40-50°C at 300-500 rpm to prepare the rubber compound:

[0027] 618 epoxy resin 20g, Wuxi Resin Factory; 170 epoxy resin 40g, South Asia resin; CTBN861340 toughening agent 30g, Shanghai Jiadida; curing agent dicyandiamide Dyhard 100S 7g, Evonik Degussa; rheology additive AEROSIL380 1g, Evonik Degussa; accelerator PN-23 1.5g, Ajinomoto; silane coupling agent KH-560 0.5g, general purpose.

[0028] 3. Impregnated glass fiber

[0029] Preheat the glue to 40-50°C, then use a brush to brush the glue on the glass fiber cloth that has been cut in advance, and dip it for later use.

Embodiment 2

[0031] 1. Preparation of curing agent

[0032] Preliminarily mix the curing agent dicyandiamide, the accelerator and the epoxy resin according to the proportion, and grind it into a paste through a three-roll mill.

[0033] 2. Preparation of rubber

[0034] Weigh the raw materials with the following mass percentages, and fully vacuum stir the raw materials at a temperature of 40-50°C at 300-500 rpm to prepare the rubber compound:

[0035] 20g of 618 epoxy resin, Wuxi Resin Factory; 40g of 170 epoxy resin, Nanya resin; 30g of MX154 toughening agent, Japan Zhongyuan Chemical; curing agent dicyandiamide Dyhard 100S 7g, Evonik Degussa; rheological additive AEROSIL380 1g, Evonik Degussa; accelerator PN-23 1.5g, Ajinomoto; silane coupling agent KH-560 0.5g, general purpose.

[0036] 3. Impregnated glass fiber

[0037] Preheat the glue to 40-50°C, then use a brush to brush the glue on the glass fiber cloth that has been cut in advance, and dip it for later use.

Embodiment 3

[0039] 1. Preparation of toughening agent

[0040] Preliminarily mix Dow core-shell particles 2670 and bisphenol A epoxy resin 618 at a mass ratio of 1:3, stir and disperse at a high speed at 60-90°C to form a uniform single colloid, which is used as a toughening agent for later use.

[0041] 2. Preparation of curing agent

[0042] Preliminarily mix the curing agent dicyandiamide, the accelerator and the epoxy resin according to the proportion, and grind it into a paste through a three-roll mill.

[0043] 3. Prepare rubber

[0044] Weigh the raw materials with the following mass percentages, and fully vacuum stir the raw materials at a temperature of 40-50°C at 300-500 rpm to prepare the rubber compound:

[0045] 2g of 618 epoxy resin, Wuxi Resin Factory; 40g of 170 epoxy resin, Nanya Resin; 48g of the above-mentioned 1 toughening agent; curing agent dicyandiamide Dyhard 100S 7g, Evonik Degussa; rheological additive AEROSIL380 1g, won Chuang De Gu Sai; accelerator PN-23 1.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com