Method and equipment for producing art veins cleavage tile

A production method, technology of splitting bricks, applied in application, surface layering device, ceramic molding machine, etc., can solve problems such as easy edges and corners on the surface of particles, uncontrolled temperature, improper handling of raw materials, etc., to achieve surface appearance and internal quality Improve, improve the density and plasticity, improve the effect of drying strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

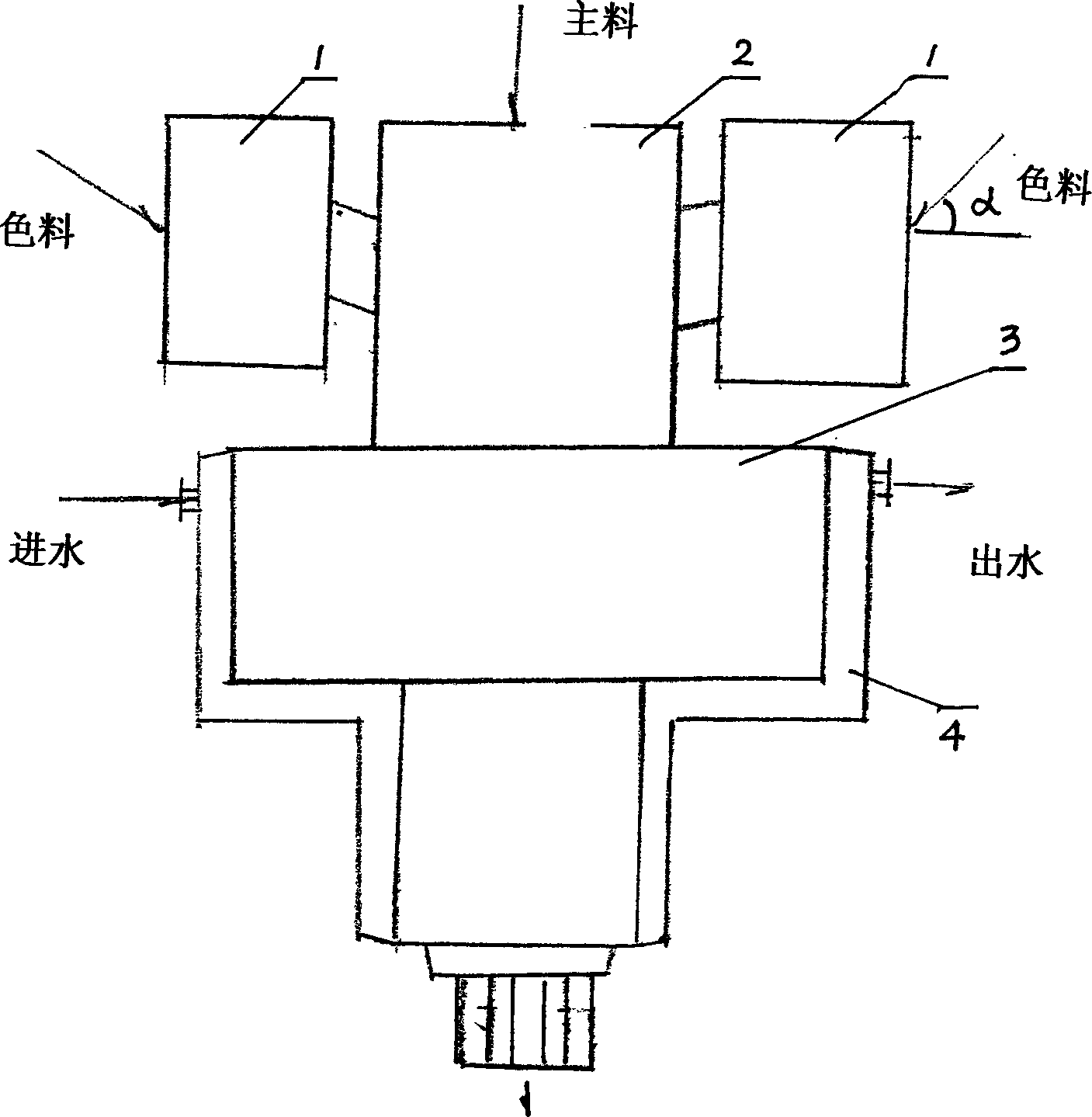

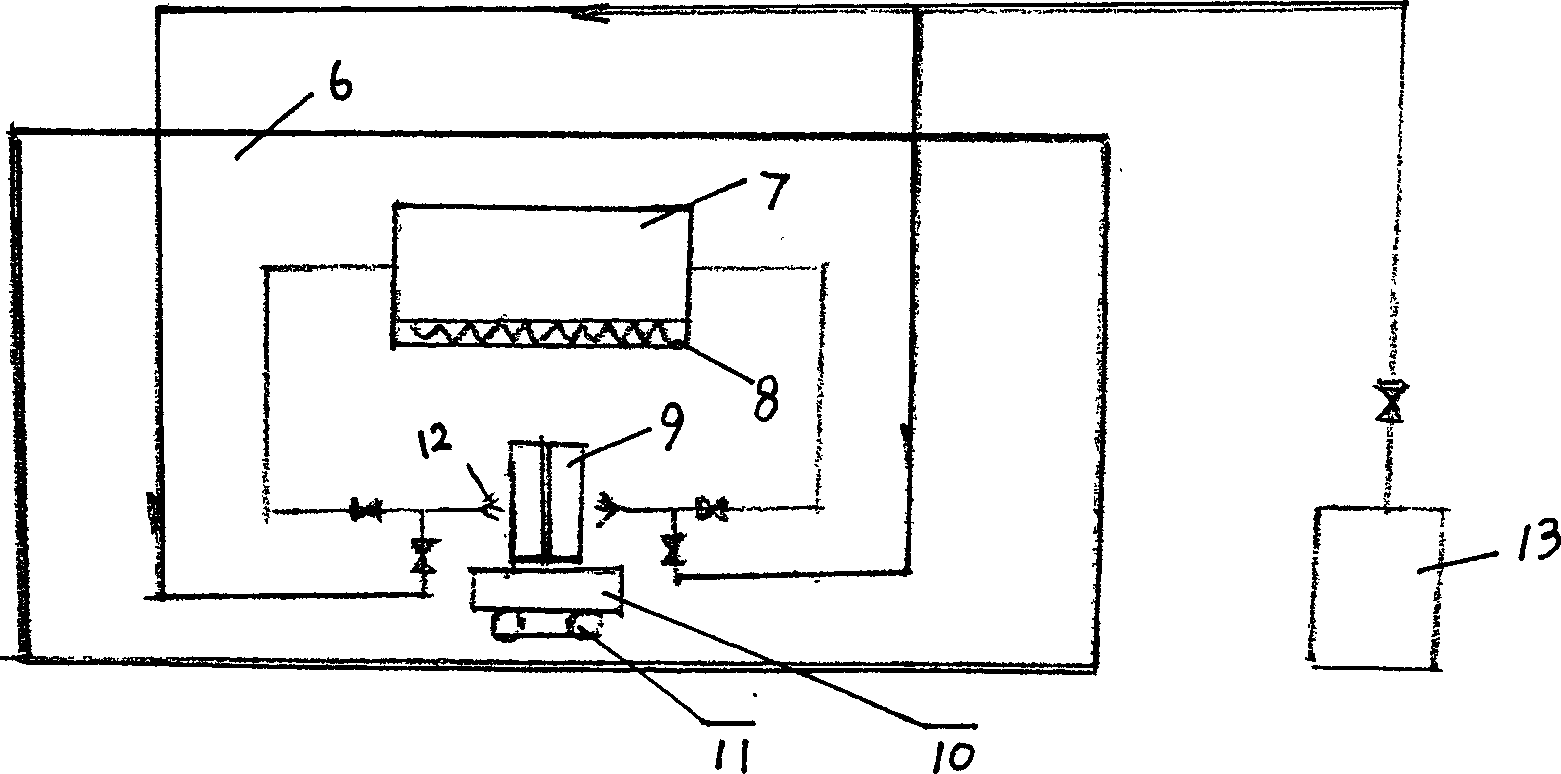

[0033] Put 570 kg of clay, 280 kg of china clay, 100 kg of feldspar, 50 kg of clinker, 5 kg of sodium humate, and 1 kg of sodium tripolyphosphate into a ball mill for wet grinding for 4-8 hours, and the moisture content of the mud should be controlled at 30% to 55%, and after grinding, the fineness will reach 200 mesh sieve and the remaining 1% to 15%. According to the production method of ordinary splitting bricks, squeeze the mud, vacuum mud, and stale for 1-3 days, control the moisture content of 16-27%, and then put the mud of two different colors into the two sides of the vacuum extruder respectively. A continuous feeding box and a continuous feeding box, continuous mixing and continuous constant temperature extrusion in the vacuum mixing box, cooling with cold water around the screw extruder, controlling the temperature of the extruded brick to 30-50 ° C, and extruding by the screw Extrude, cut and discard the skins on both sides to form two adobes with dovetail grooves ...

Embodiment 2

[0035] Put 1,800 kg of clay, 780 kg of china clay, 120 kg of talc, 300 kg of clinker, 12 kg of sodium humate, and 4.5 kg of sodium tripolyphosphate into a ball mill for wet grinding for 5-9 hours, and control the moisture content of the mud at 30% to 55 %, after grinding, the fineness reaches 1% to 15% of the 200 mesh sieve. According to the production method of ordinary splitting bricks, squeeze the mud, vacuum mud, and stale for 1-3 days, control the moisture content of 16-27%, and then put the mud of two different colors into the two sides of the vacuum extruder respectively. A continuous feeding box and a continuous feeding box, continuous mixing and continuous constant temperature extrusion in the vacuum mixing box, cooling with cold water around the screw extruder, controlling the temperature of the extruded brick to 30-60 ° C, and extruding by the screw Extrude, cut and discard the skins on both sides to form two adobes with dovetail grooves on the back, chamfers of the...

Embodiment 3

[0037] Put 2,200 kg of clay, 480 kg of shale, 760 kg of china clay, 400 kg of feldspar, 160 kg of clinker, 18 kg of sodium humate, and 8 kg of sodium pyrophosphate into a ball mill for wet grinding for 6-10 hours. At 30% to 55%, the fineness after grinding reaches 1% to 15% of 200 mesh sieve. According to the production method of ordinary splitting bricks, squeeze the mud, vacuum mud, and stale for 1-3 days, control the moisture content of 16-27%, and then put the mud of two different colors into the two sides of the vacuum extruder respectively. A continuous feeding box and a continuous feeding box, continuous mixing and continuous constant temperature extrusion in the vacuum mixing box, cooling with cold water around the screw extruder, controlling the temperature of the extruded brick to 30-50 ° C, and extruding by the screw Extrude, cut and discard the skins on both sides to form two adobes with dovetail grooves on the back, chamfers of the dovetail grooves at 20-45 degree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com