High-strength gradient full-absorption artificial ligament and preparation method thereof

An artificial ligament, full absorption technology, applied in the field of biomedical textile preparation, to achieve the effects of high-strength mechanical properties, avoidance of secondary weaving and dense pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of a high-strength gradient fully absorbable artificial ligament:

[0034] Step 1: Determine the yarn and ligament structure parameters

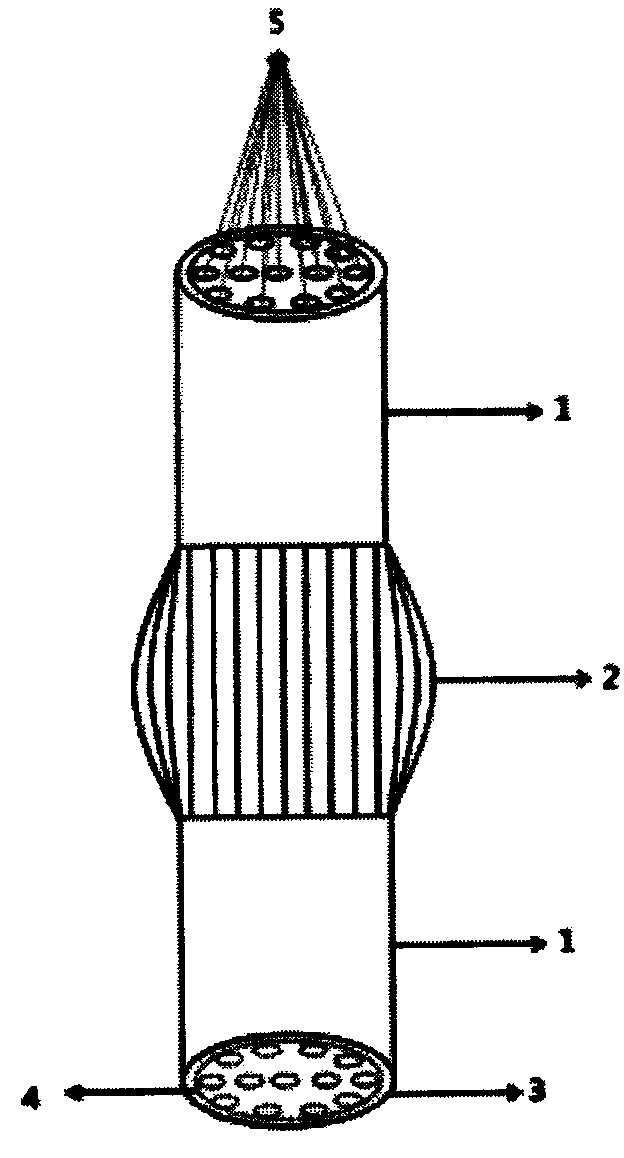

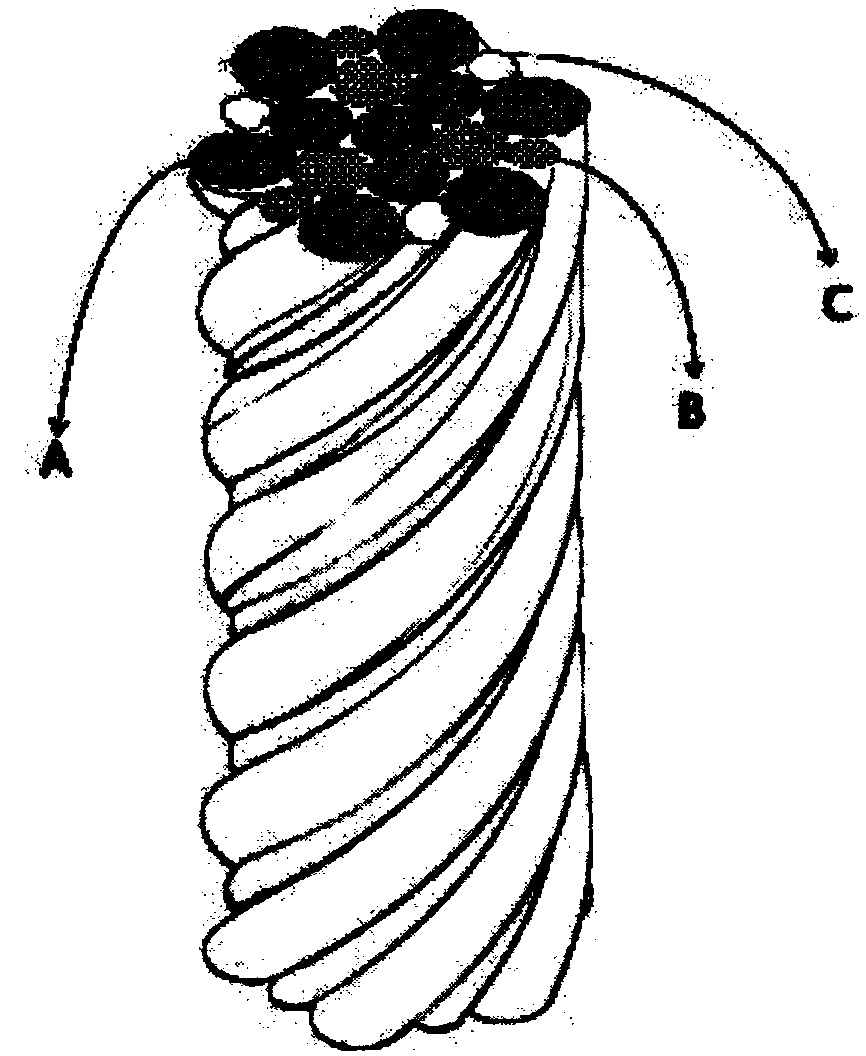

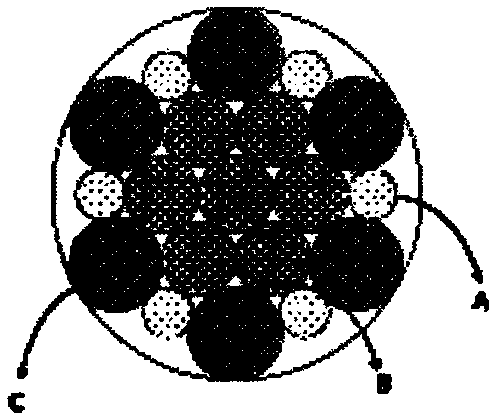

[0035]Fiber A, fiber B, and fiber C use PLA fiber, PCL fiber, and P4HB fiber respectively. The diameter of a single yarn is 0.4mm, and the complete degradation time is 12 months; the number of fibers in the cortex 3 is 40, of which 4 are PLA fibers, 14 PCL fibers and 22 P4HB fibers, the number of core yarns 5 in the core layer 4 is 10; 55%, which is schematically shown as Figure 3-1 shown.

[0036] Step 2: Preparation of Gradient Degraded Yarn

[0037] Combined and twisted 4 PLA fibers, 14 PCL fibers and 22 P4HB fibers through the combined yarn forming process with a twisting speed of 3000r / min and a twist angle of 20° to prepare a single yarn That is, the skin layer 3 of the skin-core double-layer tubular structure; the core layer 4 of the skin-core double-layer tubular structure with uniform tension is obta...

Embodiment 2

[0043] A preparation method of a high-strength gradient fully absorbable artificial ligament:

[0044] Step 1: Determine the yarn and ligament structure parameters

[0045] Fiber A, fiber B, and fiber C use PLA fiber, PCL fiber, and P4HB fiber respectively. The diameter of a single yarn is 0.8mm, and the complete degradation time is 13 months; the number of fibers in the cortex 3 is 80, of which 16 are PLA fibers, 16 PCL fibers and 48 P4HB fibers, the number of core yarns 5 in the core layer 4 is 30; 60%, the schematic diagram is as Figure 3-2 shown.

[0046] Step 2: Preparation of Gradient Degraded Yarn

[0047] 16 PLA fibers, 16 PCL fibers and 48 P4HB fibers were combined and twisted through the composite yarn forming process of the covered yarn method. The twisting speed was 4000r / min, and the twist angle was 40°. The prepared single yarn That is, the cortex 3 of the skin-core double-layer tubular structure; the core layer 4 of the skin-core double-layer tubular struct...

Embodiment 3

[0053] A preparation method of a high-strength gradient fully absorbable artificial ligament:

[0054] Step 1: Determine the yarn and ligament structure parameters

[0055] Fiber A, fiber B, and fiber C use PLA fiber, PCL fiber, and P4HB fiber respectively. The diameter of a single yarn is 1mm, and the complete degradation time is 15 months; the number of fibers in the cortex 3 is 100, of which 10 are PLA fibers, 10 PCL fibers and 80 P4HB fibers, the number of core yarns 5 in the core layer 4 is 50; 80%, the schematic diagram is as Figure 3-3 shown.

[0056] Step 2: Preparation of Gradient Degraded Yarn

[0057] The single yarn prepared by combining and twisting 10 PLA fibers, 10 PCL fibers and 80 P4HB fibers through the composite yarn forming process by wrapping yarn method, the twisting speed is 5000r / min, and the twist angle is 60° That is, the skin layer 3 of the skin-core double-layer tubular structure; the core layer 4 of the skin-core double-layer tubular structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com