Device and method for measuring volume change rate of phase change power system

A volume change rate, dynamic system technology, applied in the investigation phase/state change and other directions, can solve the problems of inability to real-time, low accuracy of results, not considering the influence of volume value, etc., to improve measurement accuracy, high degree of automation, The effect of the simple structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

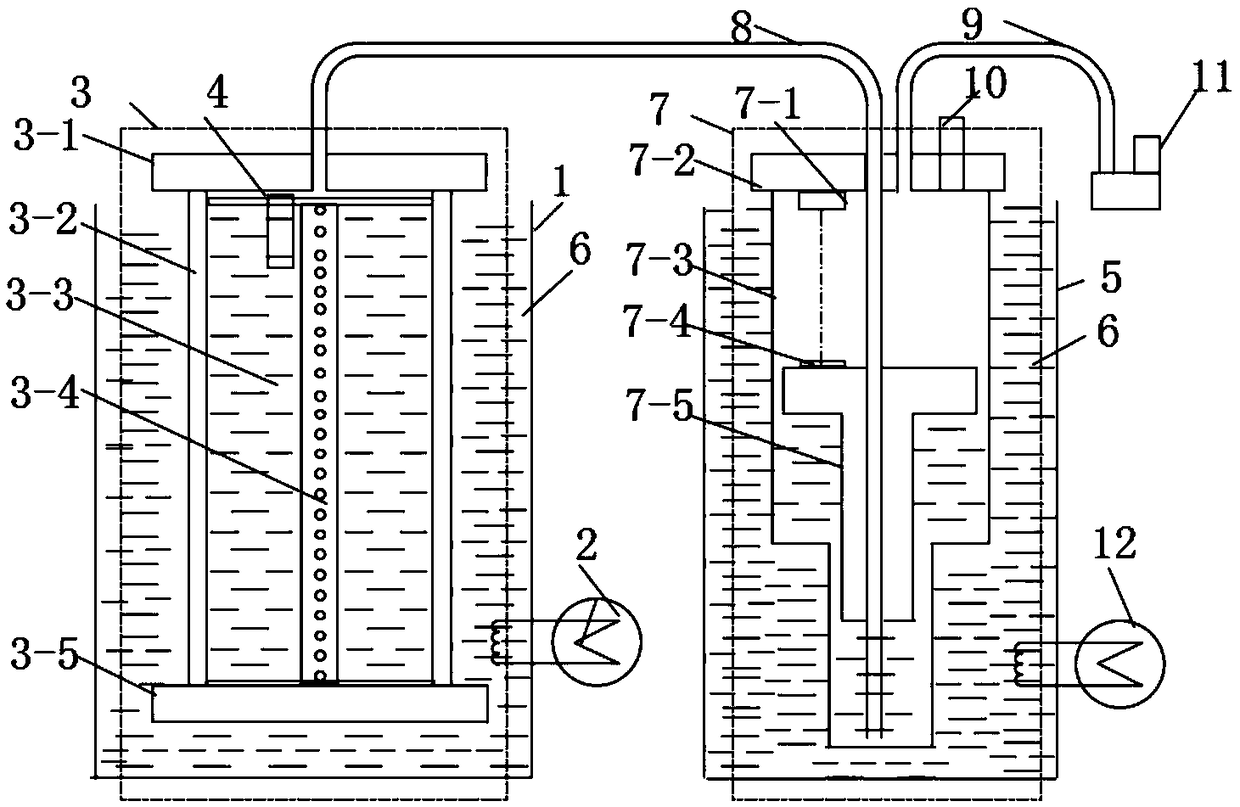

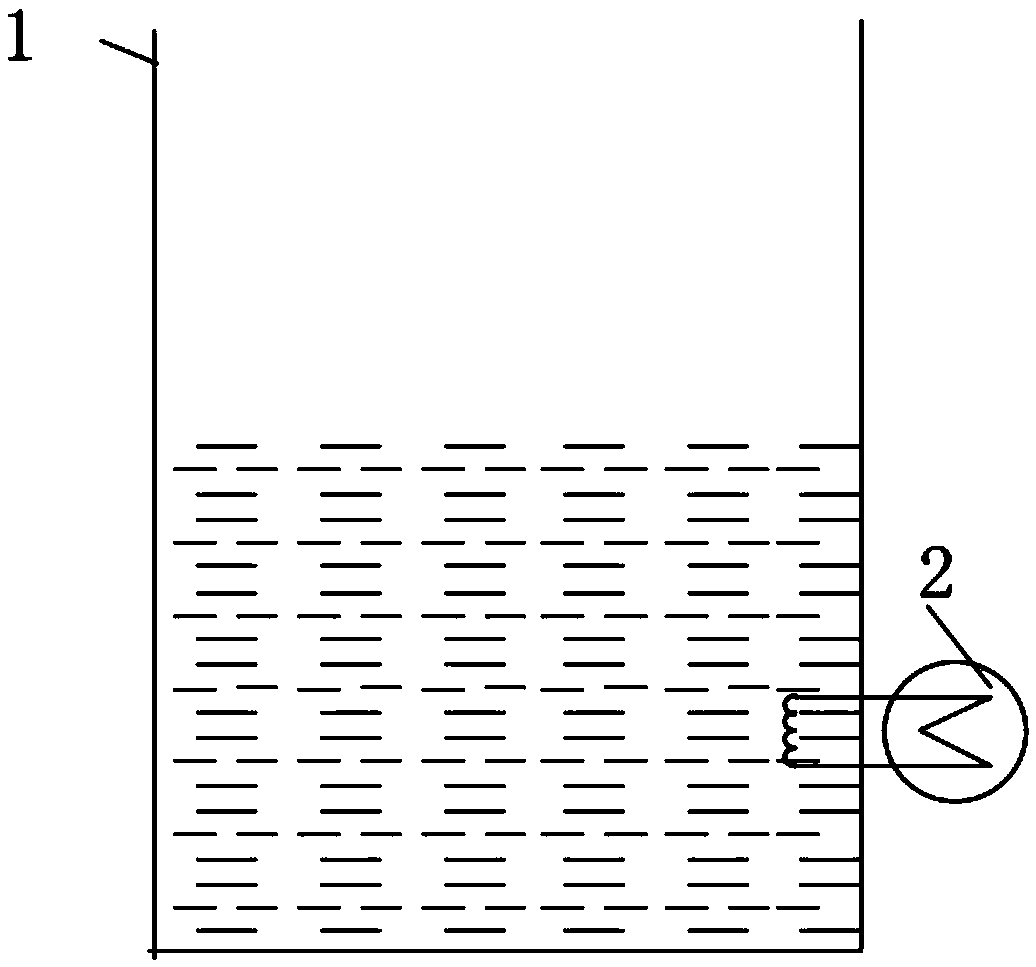

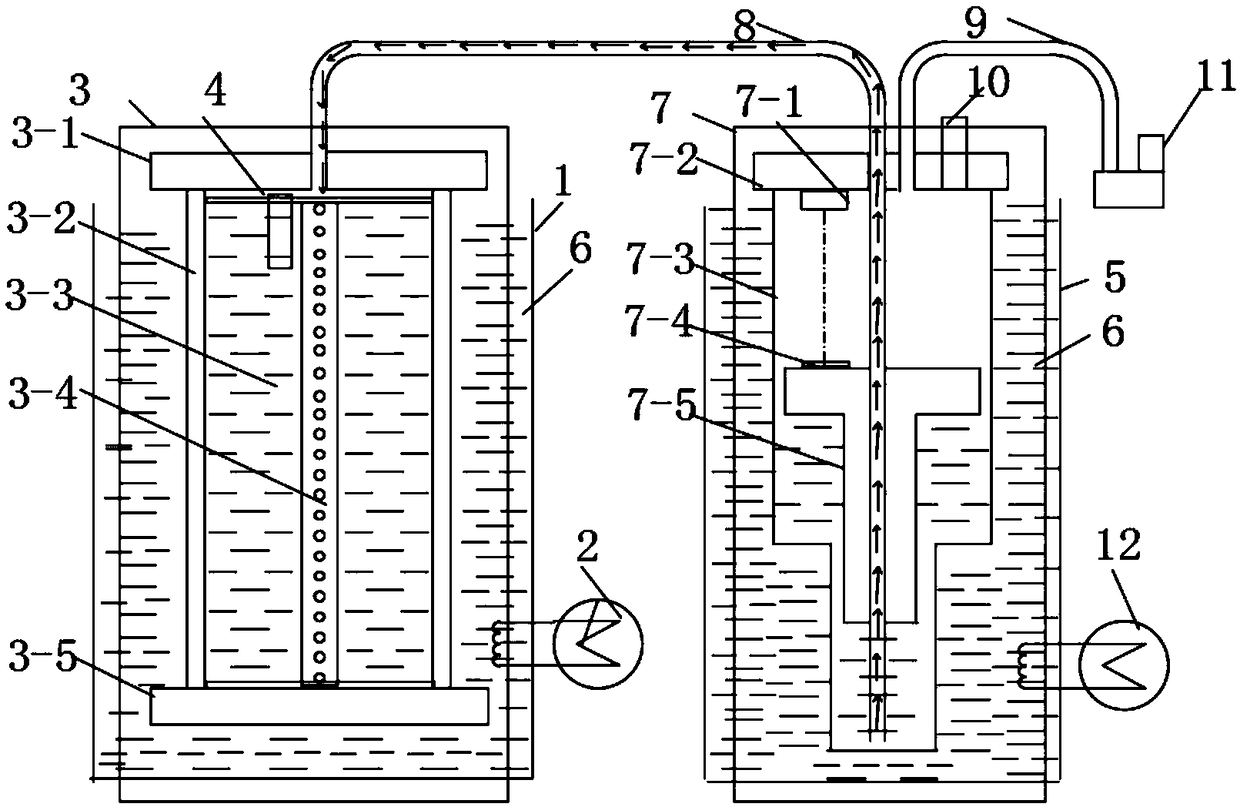

[0039] This embodiment provides a device for measuring the volume change rate of a phase change power system under variable temperature and variable pressure conditions.

[0040] like Figure 1a and 1b As shown, a device for measuring the volume change rate of a phase change power system under variable temperature and pressure conditions, including a phase change power system 3, a liquid replenishment system 7, and a temperature and pressure control system. The phase-change power system 3 includes: adiabatic top cover, heat pipe, phase-change material, adiabatic liquid replenishment column, heat-insulated bottom cover, and the first connecting pipe 8; the phase-change rehydration system 7 includes: a laser displacement sensor, a heat-insulated top cover of a rehydration pipe, a rehydration pipe Tubes, reflectors, floating columns; variable temperature and variable pressure control system includes: constant temperature water tank 1 with variable temperature, first cooling and h...

Embodiment 2

[0044] This embodiment provides a measurement method for a volume change rate measuring device of a phase change power system under variable temperature and variable pressure conditions, including the following steps:

[0045] For the phase change material volume V loaded into the phase change power system 3 0 Calibrate. Introduce the phase change material into the graduated cylinder, and record the volume v of the phase change material in the graduated cylinder 1 , put the phase change material from the graduated cylinder into the heat conduction tube of the phase change power system 3 and fill it with the phase change material, record the volume v of the phase change material in the graduated cylinder 2 , to get the volume V of the phase change material loaded into the phase change power system 3 0 =v 1 -v 2 .

[0046] The diameter of the rehydration tube d 0 Carry out calibration Use a vernier caliper to measure the diameter of the rehydration tube radially and equall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com