Control method capable of independently controlling on-time opening and closing of runners in pouring system

A pouring system and independent control technology, applied in manufacturing tools, casting equipment, molds, etc., can solve the problems of limiting the freedom of the process, reducing the yield of the process, increasing the difficulty of process design, etc. Road design free and flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

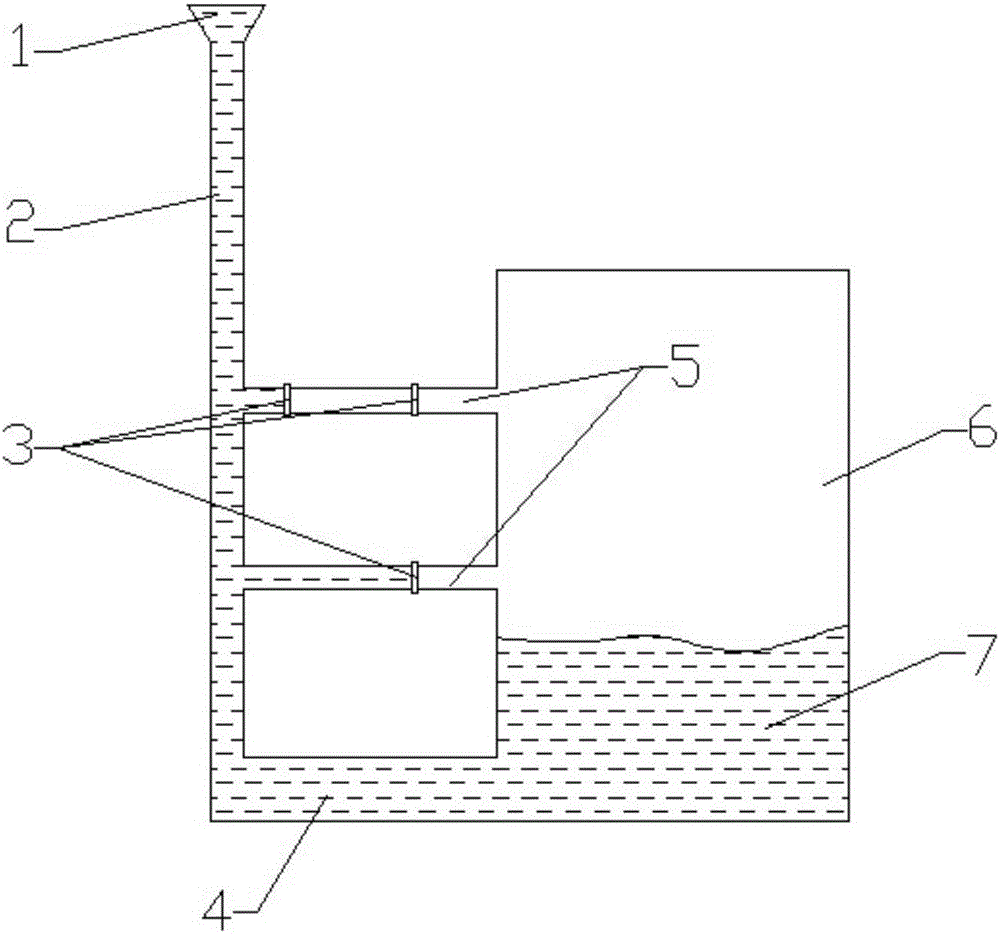

[0030] A ductile iron casting, the casting method is lost foam casting, and the gating system adopts the independent control runner timing opening and closing gating system of the present invention, such as figure 1 The stepped gating system shown. The molten metal 7 is introduced into the cavity 6 through the sprue cup 1, the sprue 2, and the bottom-up ingate.

[0031] The pouring temperature is 1430°C, and the total filling time is designed to be 30 seconds. In order to realize the opening and closing of the inner runners of each layer of the stepped gating system layer by layer, the method of independently controlling the timing opening and closing of the runners described in the present invention is adopted:

[0032] Design the second-layer in-runner in the upper-layer in-runner to open 10 seconds after filling, and replace the bottom-layer in-runner to introduce molten metal. To achieve this purpose, a piece of eutectic cast iron spoiler with a thickness of 0.8mm is emb...

Embodiment 2

[0036] A ductile iron casting, the casting method is resin sand casting, using the independent control runner timing opening and closing pouring system of the present invention, such as figure 1 The stepped gating system shown. The molten metal 7 is introduced into the cavity 6 through the sprue cup 1, the sprue 2, and the bottom-up ingate.

[0037] The pouring temperature is 1360°C, and the total filling time is designed to be 24 seconds. In order to realize the opening and closing of the inner runners of each layer of the stepped gating system layer by layer, the method of independently controlling the timing opening and closing of the runners described in the present invention is adopted:

[0038] The spoiler material is selected as eutectic aluminum-silicon alloy, and the predetermined melting time at 1360°C is 8 seconds. It is determined by experiments that its thickness should be 1.5mm.

[0039]The second-layer in-runner in the upper-layer in-runner is designed to open...

Embodiment 3

[0042] An aluminum-silicon alloy casting, the casting method is metal mold casting, and the pouring system adopts such as figure 1 The stepped gating system shown. The molten metal 7 is introduced into the cavity 6 through the sprue cup 1, the sprue 2, and the bottom-up ingate.

[0043] The pouring temperature is 1360°C, and the total filling time is designed to be 24 seconds. In order to realize the introduction of molten metal layer by layer in the inner runner of each layer of the stepped gating system, the method of independently controlling the timing opening and closing of the runner described in the present invention is adopted:

[0044] The spoiler material is selected as eutectic aluminum-silicon alloy, and the predetermined melting time at 1360°C is 8 seconds. It is determined by experiments that its thickness should be 1.5mm.

[0045] The second-layer in-runner in the upper-layer in-runner is designed to open 8 seconds after the filling starts, and replace the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com