Solder ball and electronic member

A technology of electronic components and solder balls, which is applied in the direction of electrical components, electrical components assembled printed circuits, printed circuits, etc., to achieve excellent thermal fatigue characteristics, good drop impact resistance, and the effect of suppressing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

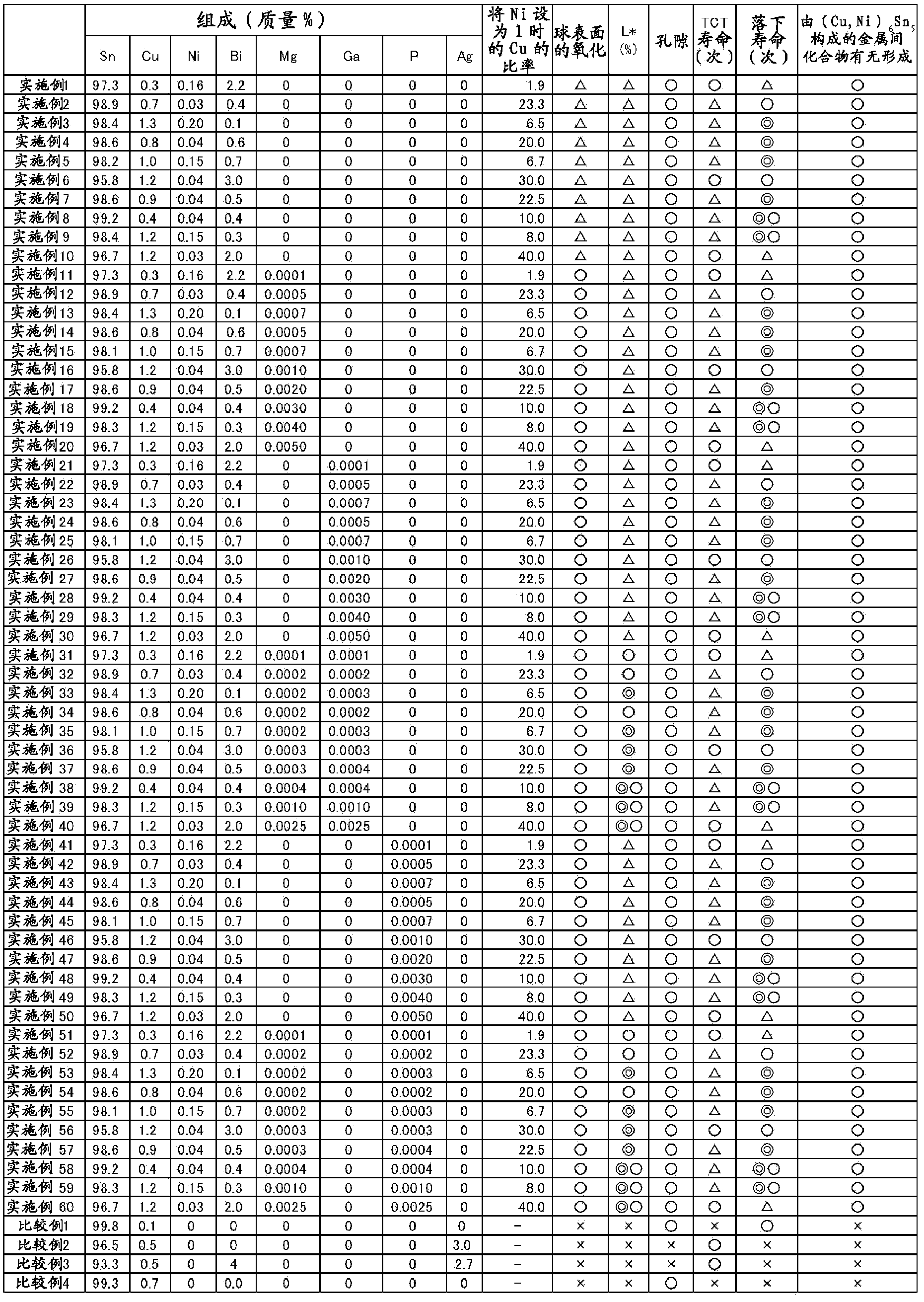

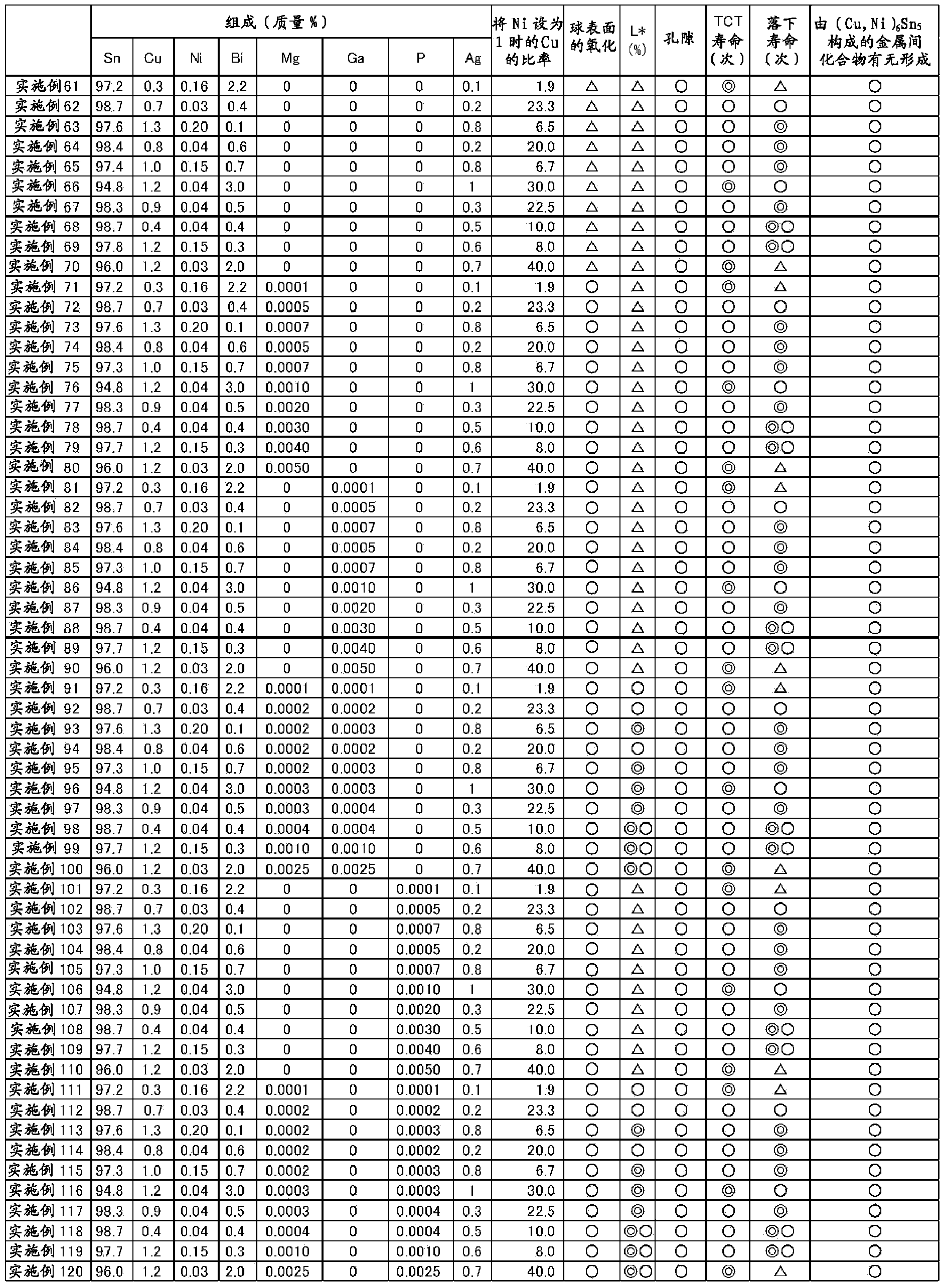

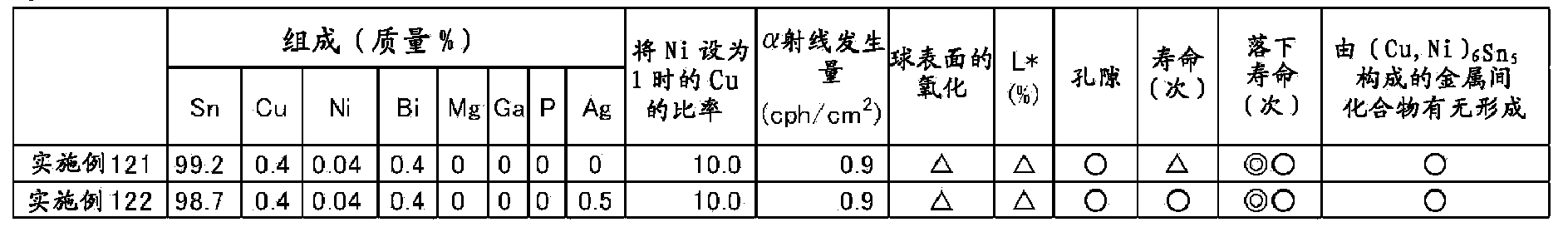

[0065] The composition of the solder alloy used as solder balls was changed, and the ball surface of each solder ball, the presence or absence of voids, thermal fatigue characteristics (TCT characteristics), and drop impact resistance characteristics (drop characteristics) were investigated. Here, a predetermined amount of Cu and Ni are heated to 275[°C] in a high-frequency melting furnace in advance to form a master alloy, and after producing a Cu-Ni-based master alloy, add Bi etc. This master alloy (Cu-Ni-based master alloy) was added to the Sn-Bi-based raw material to produce a raw material. Next, this raw material was placed in a graphite crucible, heated to 275[° C.] in a high-frequency melting furnace to be melted, and then cooled to obtain a solder alloy for semiconductor mounting.

[0066] Thereafter, the solder alloy was made into a wire rod having a wire diameter of 20 [μm]. This wire rod was cut into a constant volume at a length of 6.83 [mm], heated and melted aga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com