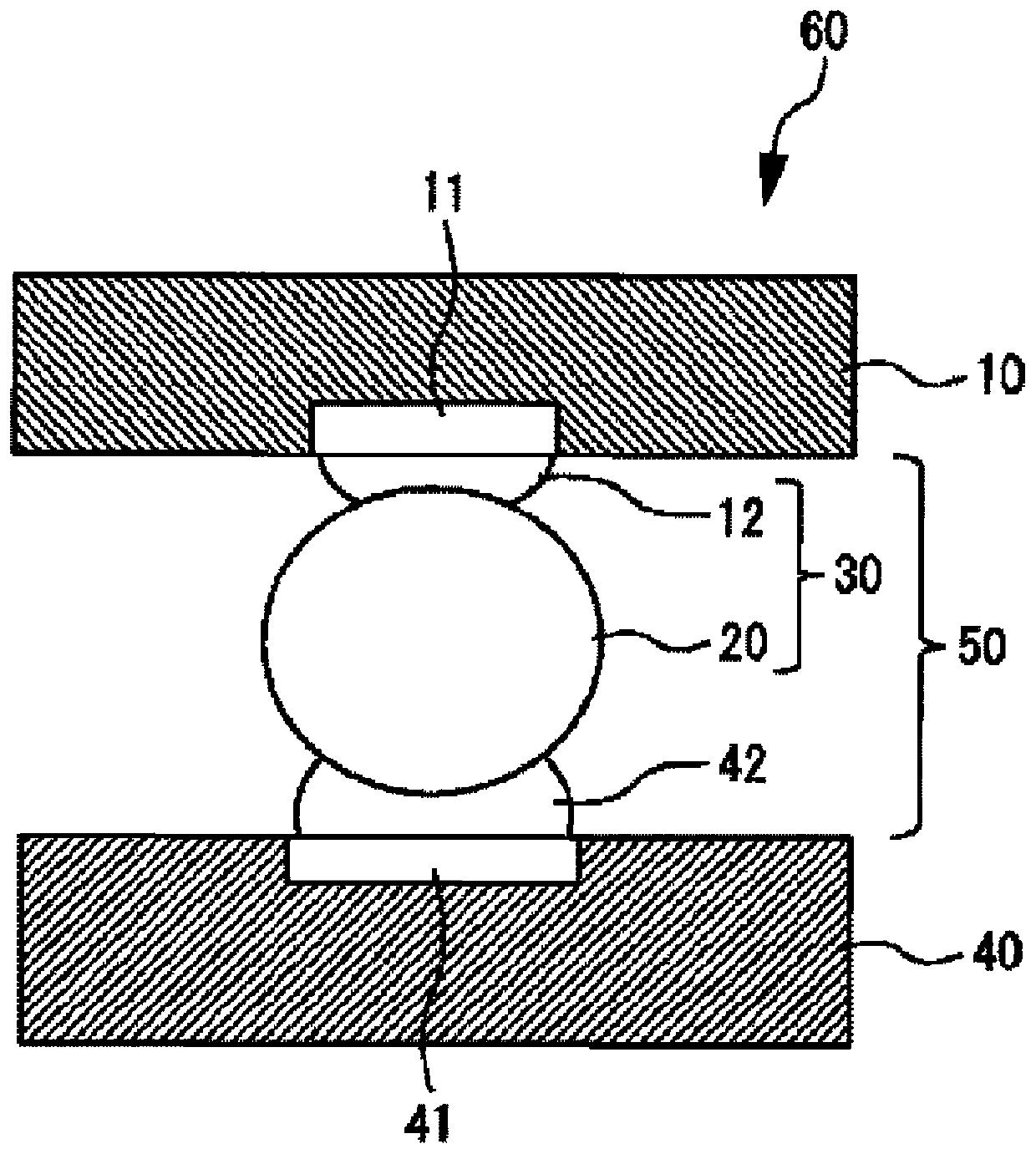

Cu BALL, OSP-TREATED Cu BALL, Cu CORE BALL, SOLDER JOINT, SOLDER PASTE, AND FOAM SOLDER, AND METHOD FOR MANUFACTURING Cu BALL

A core ball and solder paste technology, applied in the direction of welding/welding/cutting objects, welding/cutting media/materials, welding media, etc., can solve the uneven height of Cu balls, the low sphericity of Cu balls, and the inability to ensure Cu balls Self-alignment and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

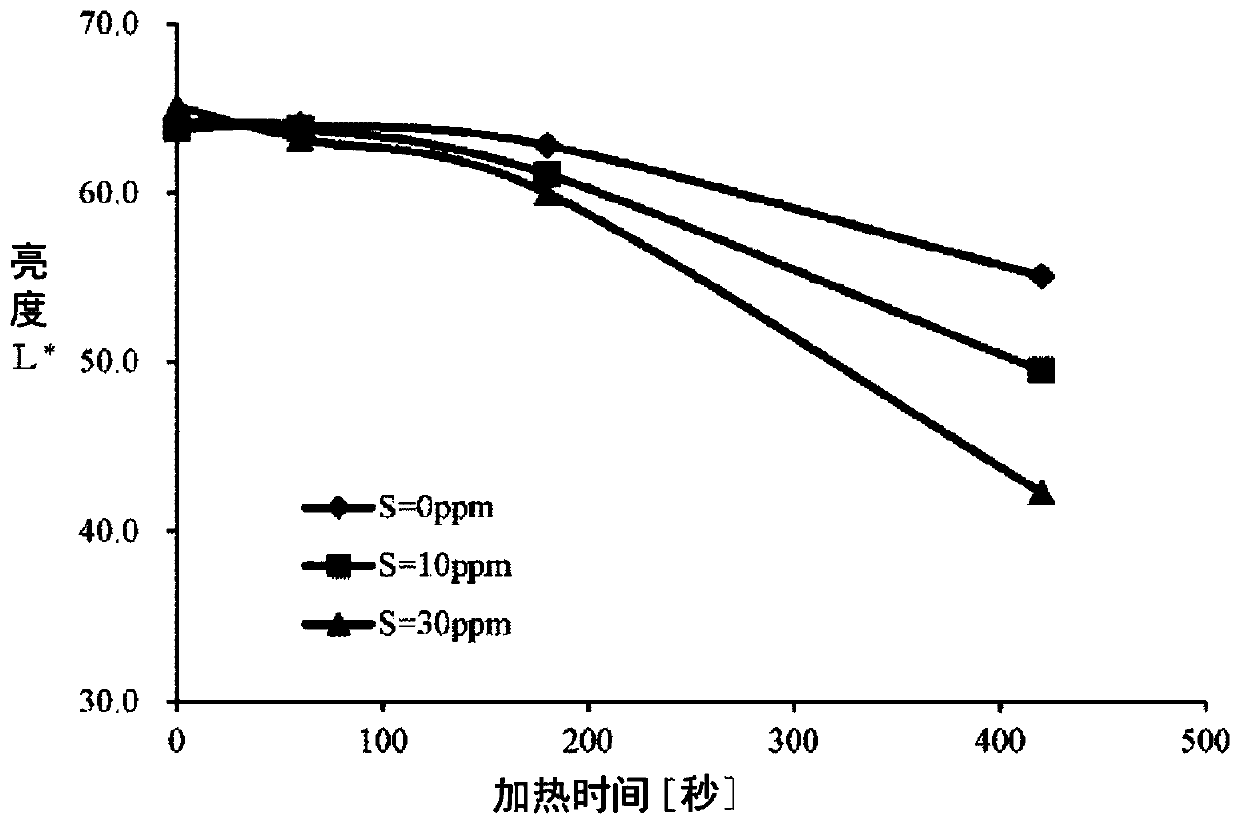

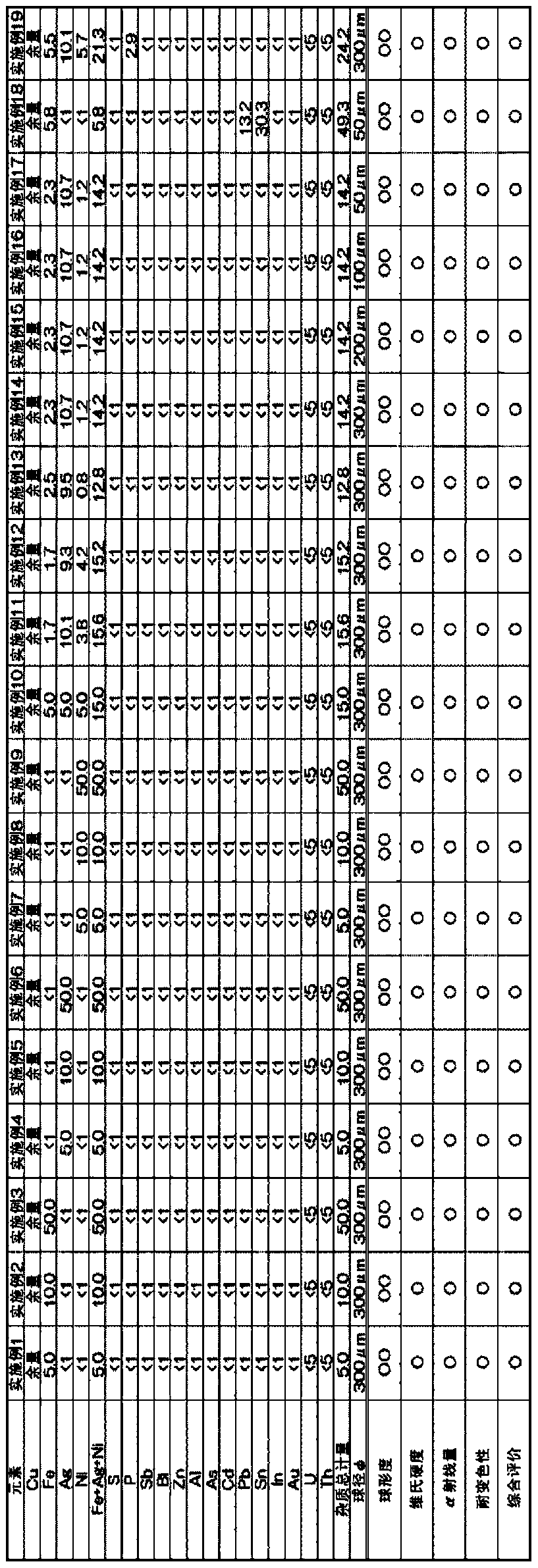

[0101] Examples of the present invention will be described below, but the present invention is limited to these. In this embodiment, Cu balls were produced, and the sphericity, Vickers hardness, α-ray dose, and discoloration resistance of the produced Cu balls were measured, and are summarized in Tables 1 and 2. In the following tables, numbers without units represent mass ppm or mass ppb. Specifically, the numerical values in the tables representing the content ratios of Fe, Ag, Ni, P, S, Sb, Bi, Zn, Al, As, Cd, Pb, In, Sn, and Au represent ppm by mass. The numerical values showing the content ratios of U and Th in the table represent ppb by mass. In addition, the "total amount of impurities" represents the total ratio of impurity elements contained in the Cu balls. "<1" indicates that the content ratio of the corresponding impurity element with respect to the Cu ball is less than 1 mass ppm. "<5" indicates that the content ratio of the corresponding impurity element w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com