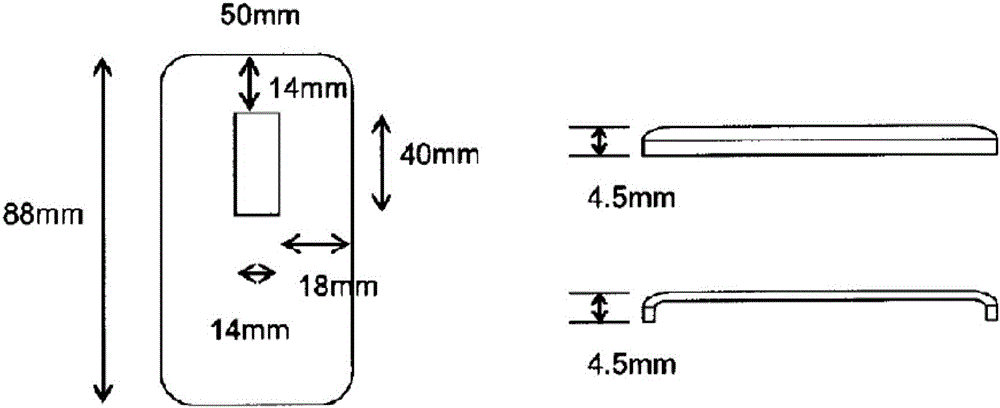

Housing for portable electronic appliance

A kind of electronic equipment and portable technology, which is applied in the field of portable electronic equipment casing, can solve unknown problems, achieve the effects of thin-walled drop impact resistance, improved impact strength, excellent fluidity and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

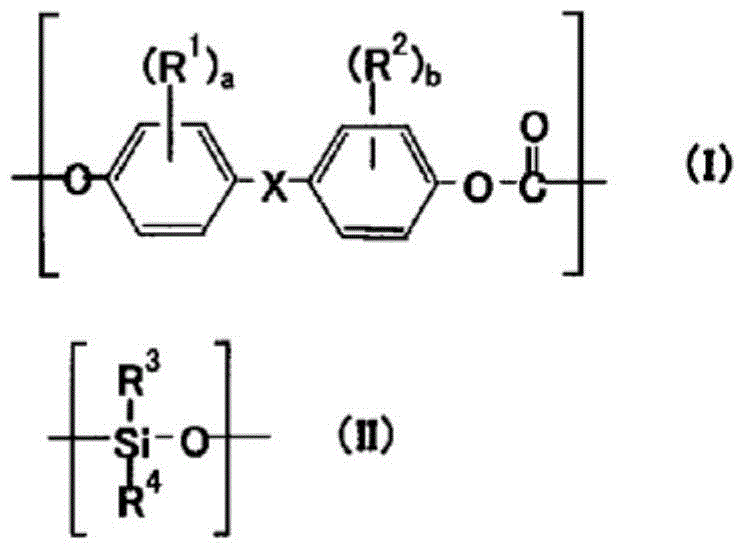

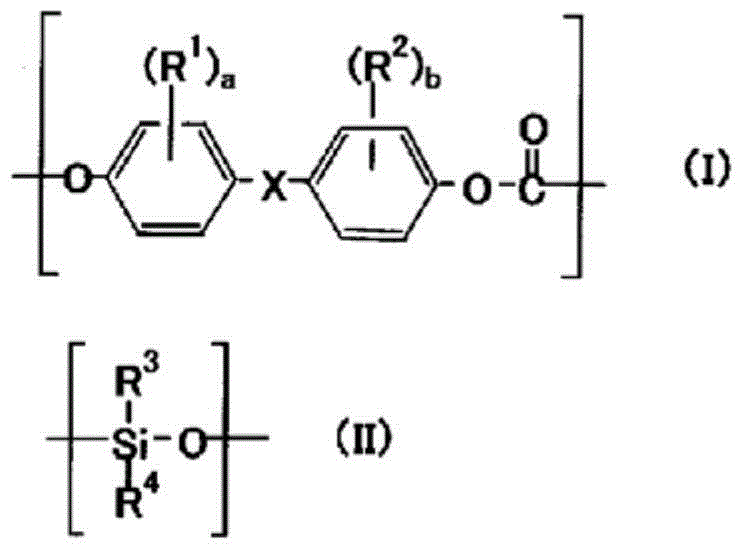

Method used

Image

Examples

manufacture example 1

[0087] Manufacture of polycarbonate oligomers

[0088] Add 2,000 ppm of sodium dithionite to bisphenol A (BPA) to be dissolved later in a 5.6 mass % sodium hydroxide aqueous solution, dissolve BPA therein so that the BPA concentration becomes 13.5 mass %, and prepare a sodium hydroxide aqueous solution of BPA .

[0089] Under the flow rate of 40 liters / hour of sodium hydroxide aqueous solution of this BPA, 15 liters / hour of dichloromethane, phosgene is passed in the tubular reactor with internal diameter 6mm, tube length 30m continuously with the flow rate of 4.0kg / hour .

[0090] The tubular reactor has a jacket part, and cooling water is passed into the jacket to keep the temperature of the reaction solution below 40°C.

[0091] The reaction solution leaving the tubular reactor is continuously introduced into a trough reactor with a baffle with an internal volume of 40 liters of swept wings, and is further supplied with 2.8 liters / hour of sodium hydroxide aqueous solutio...

manufacture example 2~9

[0102] The type of terminal-modified PDMS (allylphenol terminal-modified PDMS or eugenol terminal-modified PDMS), the number of repetitions of dimethylsiloxane units, the amount of terminal-modified PDMS, and the amount of PTBP used are as follows: As described in Table 1, a polycarbonate-polydimethylsiloxane copolymer was produced.

[0103] Table 1 shows the PDMS residue amount (PDMS copolymerization amount), viscosity number, and viscosity average molecular weight Mv of the obtained polycarbonate-polydimethylsiloxane copolymer.

[0104]

Embodiment 1~7 and comparative example 1~3

[0106] Polycarbonate-polydimethylsiloxane copolymer (PC / PDMS copolymer), FN1500 (trade name, manufactured by Idemitsu Kosan Co., Ltd., having p-tert-butyl end group) produced in Production Examples 1 to 9 BPA polycarbonate of phenol, viscosity number 39.2, viscosity average molecular weight Mv=14500), Tufflon FN1700A (trade name, Idemitsu Kosan Co., Ltd., BPA polycarbonate having p-tert-butylphenol at the end group, viscosity Number 47.1, viscosity average molecular weight Mv=17500), Taflon FN2700A (trade name, manufactured by Idemitsu Kosan Co., Ltd., BPA polycarbonate having p-tert-butylphenol at the end group, viscosity number 69.6, viscosity average molecular weight Mv=27500 ), IRGAFOS168 (trade name, manufactured by ADEKA Co., Ltd.), blended in parts by mass described in Table 2, and pelletized at a resin temperature of 280°C using a 40mmφ single-screw extruder with a vent , the pellets were obtained.

[0107] In addition, only in Comparative Example 3, the resin tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com