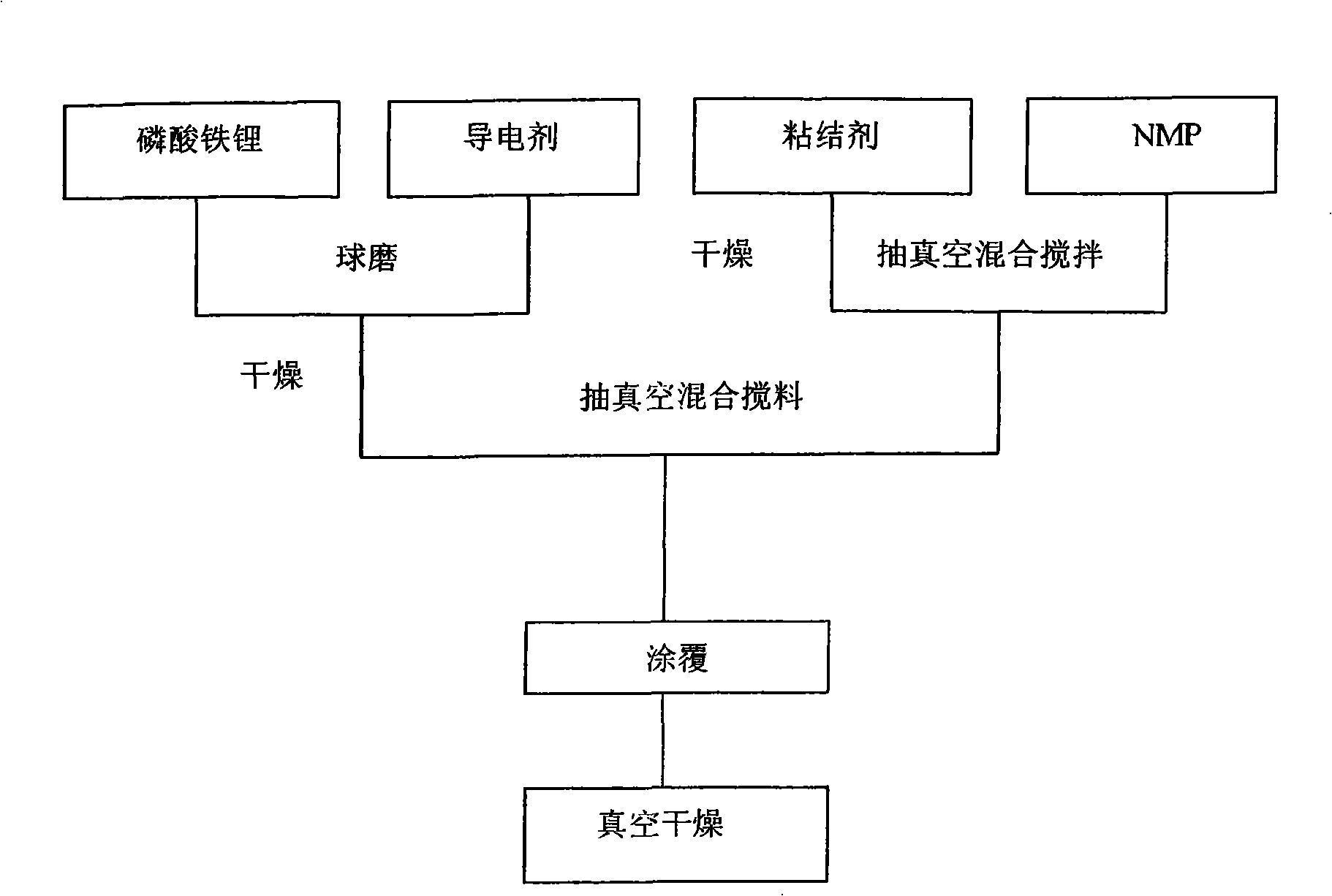

Method for vacuum mixing and coating material for lithium ion battery anode slice

A lithium-ion battery and coating method technology, which is applied to battery electrodes, electrode manufacturing, circuits, etc., can solve problems such as uneven coating, low electronic conductivity, and difficult material accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Example 1: Weigh lithium iron phosphate, conductive agent (acetylene black: graphite weight ratio=1:4) and polyvinylidene fluoride in proportion of 85%: 5%: 10%, and use polyvinylidene fluoride: 1-methyl The mass ratio of 2-pyrrolidone is 1:10 to weigh 1-methyl 2-pyrrolidone. First dry polyvinylidene fluoride at 120°C for 2 hours, then mix polytetrafluoroethylene and 1-methyl 2-pyrrolidone under vacuum and stir for 4 hours; at the same time, mix lithium iron phosphate and conductive agent for 4 hours, ball milling speed is 400r / min, and then The mixture of the two was dried at 120°C for 2 hours and then added to the above-mentioned stirred slurry. The stirring speed was 16 rpm for the dispersing wheel and 19 rpm for the orbiting wheel. Stir under vacuum for 16h. Pour the slurry into a small coater several times at a coating speed of 6r / min and a drying temperature of 100°C to coat a single layer with a thickness of 11 μm and a double layer with a thickness of 20 μm. ℃...

Embodiment 2

[0012] Embodiment 2: Weigh lithium iron phosphate positive electrode material, conductive agent (acetylene black: carbon fiber weight ratio=1: 1) and binder polyvinylidene fluoride in proportion of 86%: 6%: 8%, with polyvinylidene fluoride : 1-methyl 2-pyrrolidone mass ratio was 1: 11.25 and weighed 1-methyl 2-pyrrolidone. First dry polyvinylidene fluoride at 80°C for 4 hours to remove water, then mix polytetrafluoroethylene and 1-methyl 2-pyrrolidone under vacuum and stir for 6 hours; at the same time, mix lithium iron phosphate and conductive agent for 6 hours, and the ball milling speed is 300r / min , and then the mixture of the two was dried at 100°C for 4 hours and then added to the above-mentioned stirred slurry. The stirring speed of the dispersing wheel was 18rpm, and that of the orbital wheel was 20rpm. Stir under vacuum for 12h. Pour the slurry into a small coating machine several times at a coating speed of 5r / min and a drying temperature of 80°C to coat a single la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com