Laser welding method

一种激光焊接、激光的技术,应用在激光焊接设备、焊接设备、焊接/焊接/切割物品等方向,能够解决熔合不良等问题,达到抑制烧穿的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

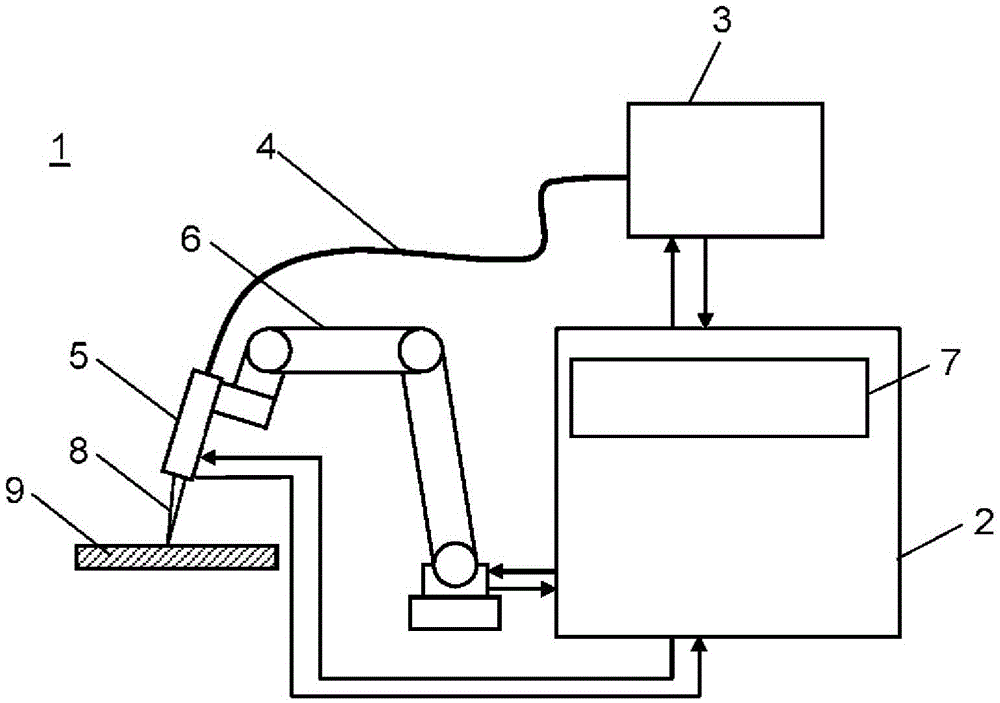

[0040] use figure 1 The structure of the laser welding apparatus in this embodiment is demonstrated. figure 1 It is a figure which shows the schematic structure of the laser welding apparatus 1 in this embodiment.

[0041] exist figure 1 Among them, a laser welding device 1 has a control unit 2 , a laser oscillator 3 , an optical fiber 4 , a laser irradiation head 5 , and a manipulator 6 .

[0042] In the laser welding device 1 , the controller 2 is connected to the laser oscillator 3 , the laser irradiation head 5 , and the manipulator 6 to control the operations of the laser oscillator 3 , the laser irradiation head 5 , and the manipulator 6 . In addition, the control part 2 has the output switching part 7 which switches the energy of the laser light output from the laser oscillator 3. Laser oscillator 3 outputs laser light 8 based on an instruction from control unit 2 . The optical fiber 4 is connected to the laser oscillator 3 and the laser irradiation head 5 , and tra...

Embodiment approach 2

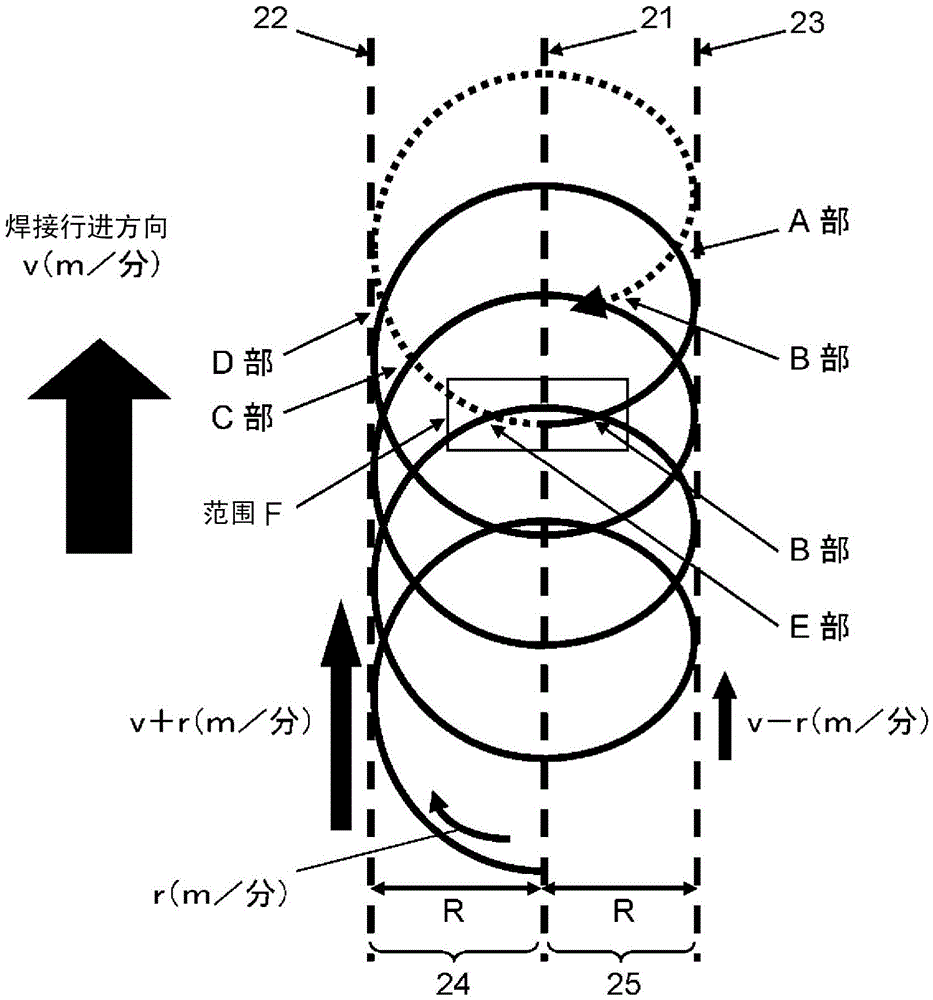

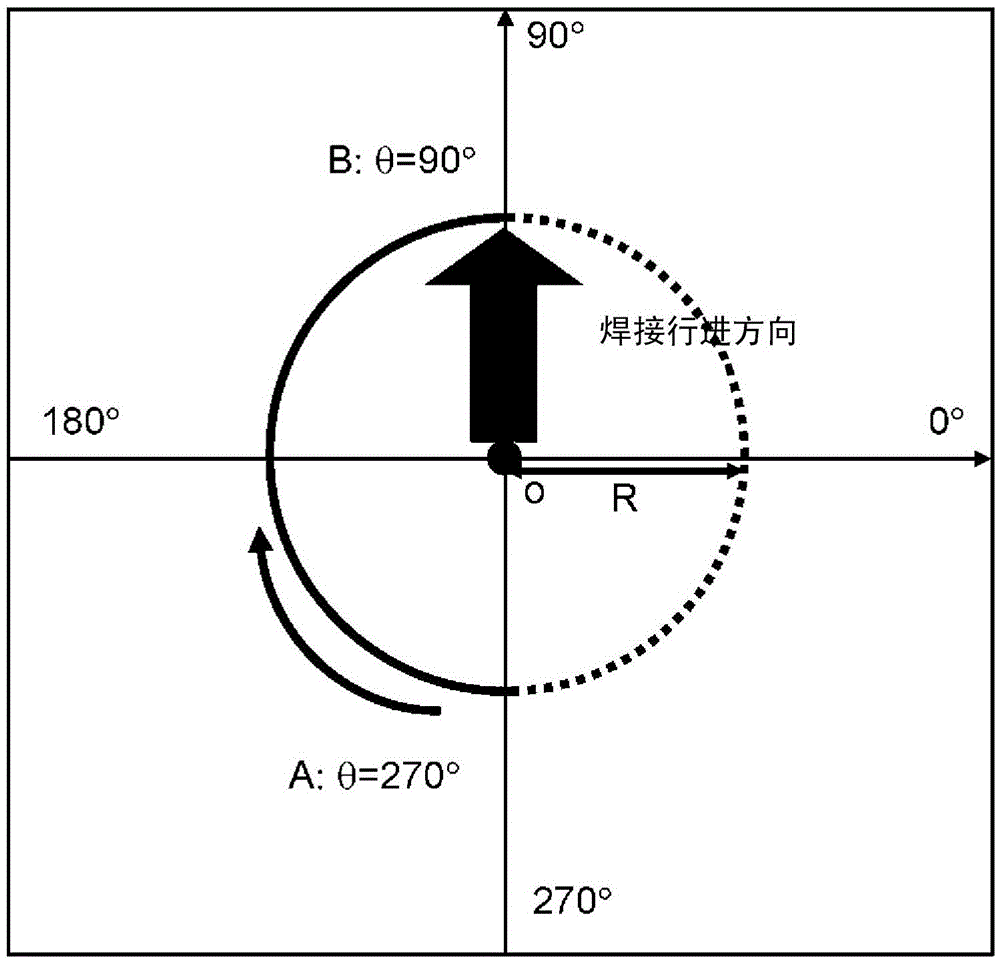

[0075] Next, use Figure 12 to Figure 20 Embodiment 2 of the present disclosure will be described. In this embodiment, the same parts as in Embodiment 1 are given the same reference numerals, and detailed description thereof will be omitted. The difference from Embodiment 1 is that the energy of the laser light in the front-back direction of the welding advancing direction is further taken into consideration.

[0076] In Embodiment 1, the laser welding method in which the heat input by irradiation of the laser beam is symmetrical in the left-right direction with respect to the welding progress direction was described. In the present embodiment, the amount of heat input by irradiation of laser light in the front-rear direction of the welding proceeding direction is controlled. This does not mean that the heat input by laser irradiation must be symmetrical in the front-back direction of the welding advancing direction, but requires an optimal heat input balance in the front-ba...

Embodiment approach 3

[0083] Next, use Figure 22 Embodiment 3 of the present disclosure will be described. In this embodiment, the same parts as in Embodiment 1 are given the same reference numerals, and detailed description thereof will be omitted. The difference from Embodiment 1 is that, similarly to Embodiment 2, the energy of the laser light in the front-back direction of the welding advancing direction is also taken into consideration. Also, the difference from Embodiment 2 is that the total amount of laser energy applied to the rear in the welding advancing direction is larger than the total amount of laser energy applied to the front in the welding advancing direction. In this embodiment, similarly to Embodiment 2, it is not necessary to make the heat input by irradiation of the laser beam symmetrical in the front-back direction of the welding advancing direction, but requires an optimal balance of heat input in the front-back direction.

[0084] When the workpiece 9 is, for example, a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com