Electroconductive paste for solar cell, solar cell, manufacturing method thereof, and solar cell module

A solar cell and conductive paste technology, applied to conductive materials, circuits, electrical components, etc. dispersed in non-conductive inorganic materials, can solve problems such as battery efficiency decline, improve electrical connections, improve battery efficiency, and solve battery problems. The effect of reduced efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

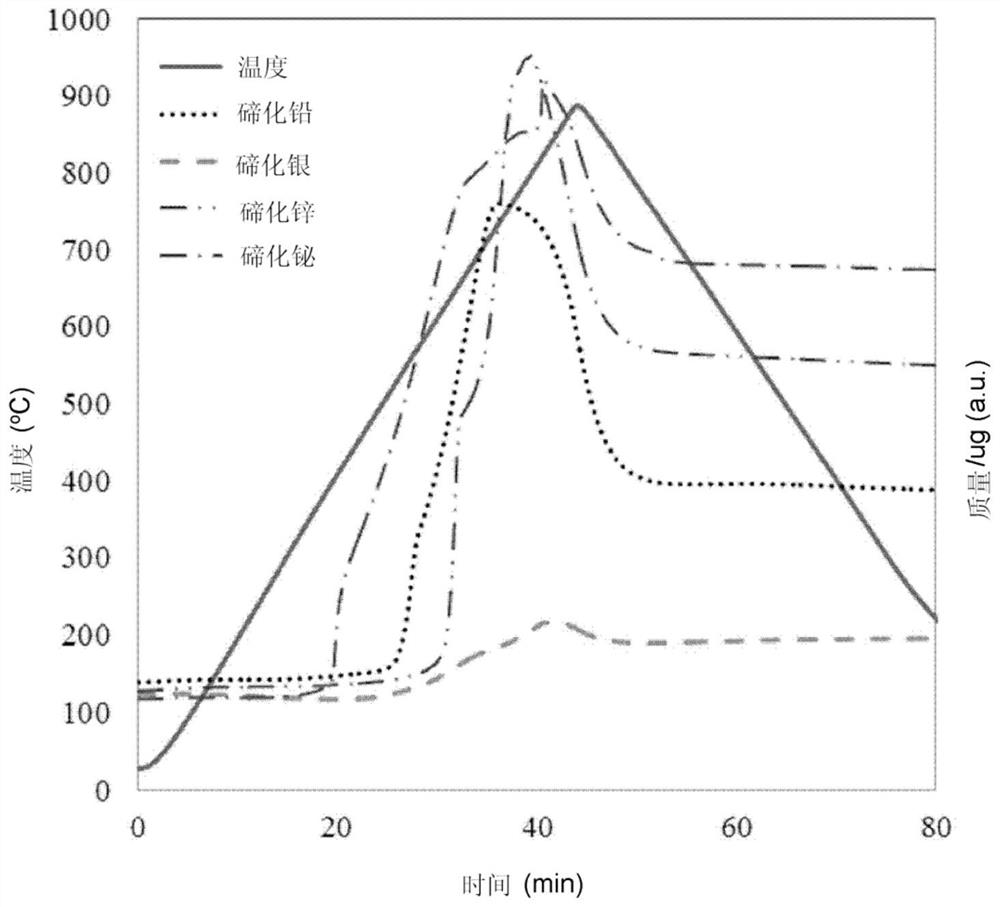

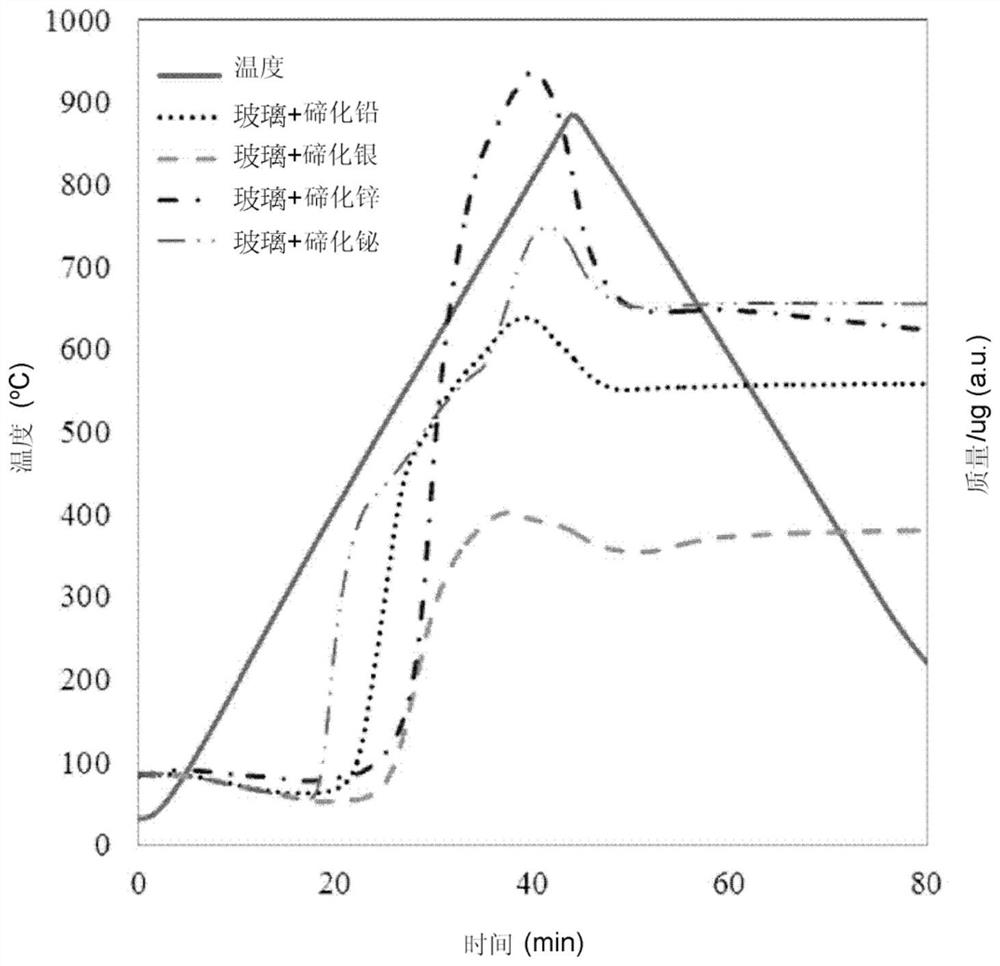

[0037] In order to prove that the electroconductive paste of the present invention can improve the electrical connection and improve the efficiency of the battery, the following experiment example is specially made.

[0038] Preparation of conductive paste and performance evaluation of solar cells

[0039] The conductive pastes for solar cells were prepared with the contents of the components listed in Tables 1 to 5 below, and their solar cell properties were measured, including fill factor FF and conversion efficiency NCell. In Table 1 to Table 5, the addition amount of the tellurium alloy compound and the glass is based on the total weight of the conductive paste, and the unit is weight percent.

[0040] The preparation method is to first mix about 60 grams to about 95 grams of silver powder, about 0.01 grams to about 7 grams of glass, about 5 grams to about 40 grams of organic carrier and about 0.01 grams to about 5 grams of tellurium alloy The compounds are mixed and disp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com