Microwave curing method of double vacuum bags for carbon fiber composite parts

A composite material and microwave curing technology, which is applied in the field of microwave heating curing molding and rapid curing molding of carbon fiber composite materials, can solve the problems of carbon fiber discharge, easy to produce discharge, etc., and achieve the effect of improving the degree of compaction, easy control, and uniform temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention is not limited to the embodiments.

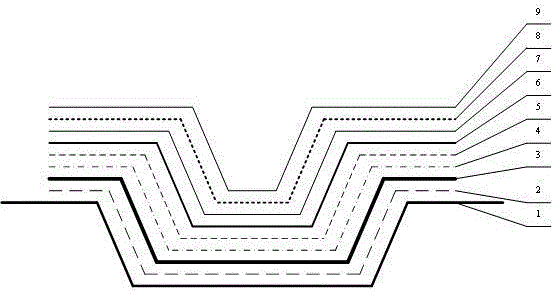

[0018] Such as figure 1 shown.

[0019] A double-vacuum bag microwave curing method for carbon fiber composite parts, which uses two layers of vacuum bags 7 and 9 to seal and pressurize the carbon fiber composite part 3 to be cured, and adds a layer of high temperature resistance between the two layers of vacuum bags The flexible material 8 (such as aluminum silicate material), and then put the packaged carbon fiber composite material into the microwave heating and curing equipment for heating and curing.

[0020] The closed pressurized part of the double vacuum bag is to seal two layers of vacuum bags on the carbon fiber composite material part 3 to be cured: the inner vacuum bag 7 and the outer vacuum bag 9, and connect the two layers of vacuum bags to the outer vacuum system, thereby A va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com