Semifinished flat tube, process for producing same, flat tube, heat exchanger comprising the flat tube and process for fabricating the heat exchanger

a technology flat tubes, which is applied in the direction of tubular elements, lighting and heating apparatus, stationary conduit assemblies, etc., can solve the problems of insufficient rigidity of semi-finished flat tubes, deformation of tubes, and insufficient semi-finished flat tubes, so as to improve rigidity, prevent deformation, and the effect of high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

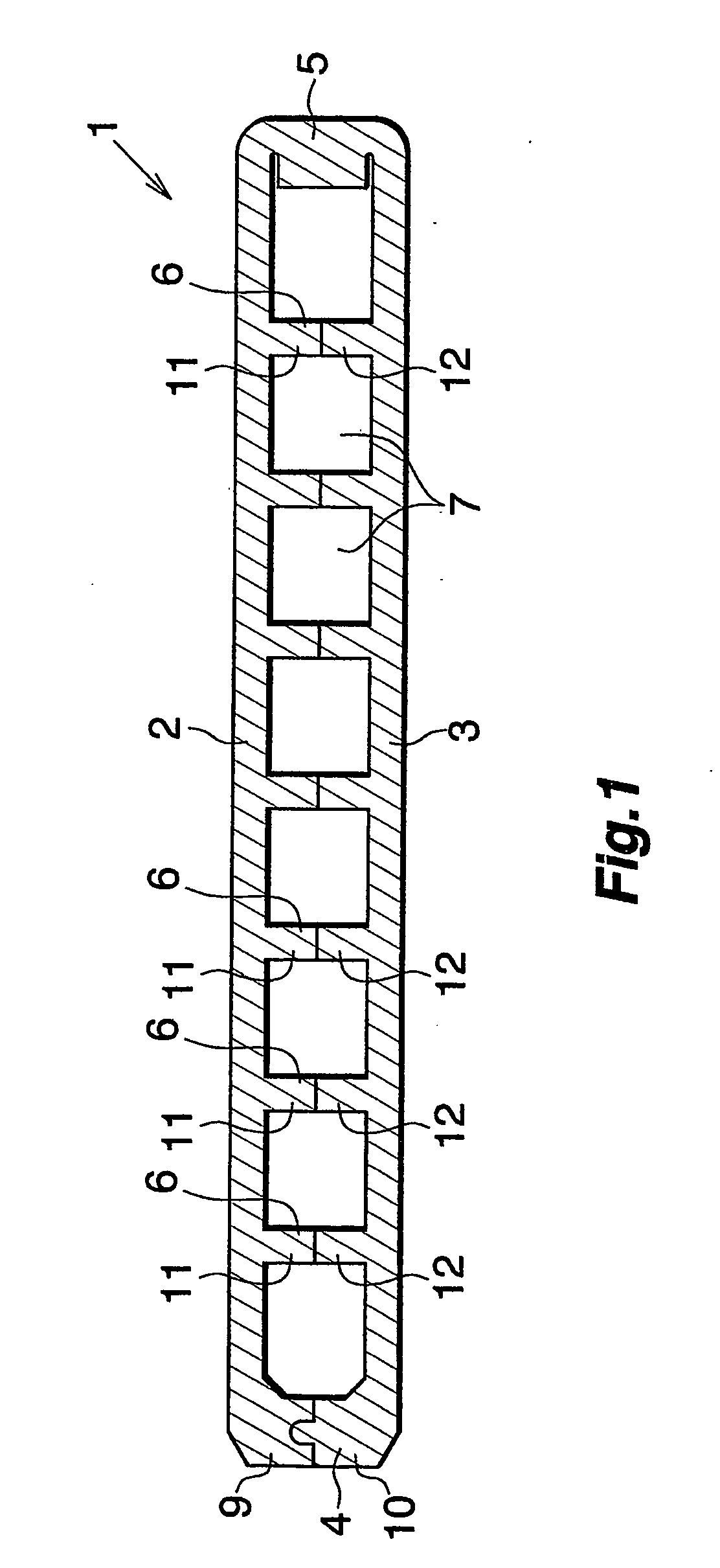

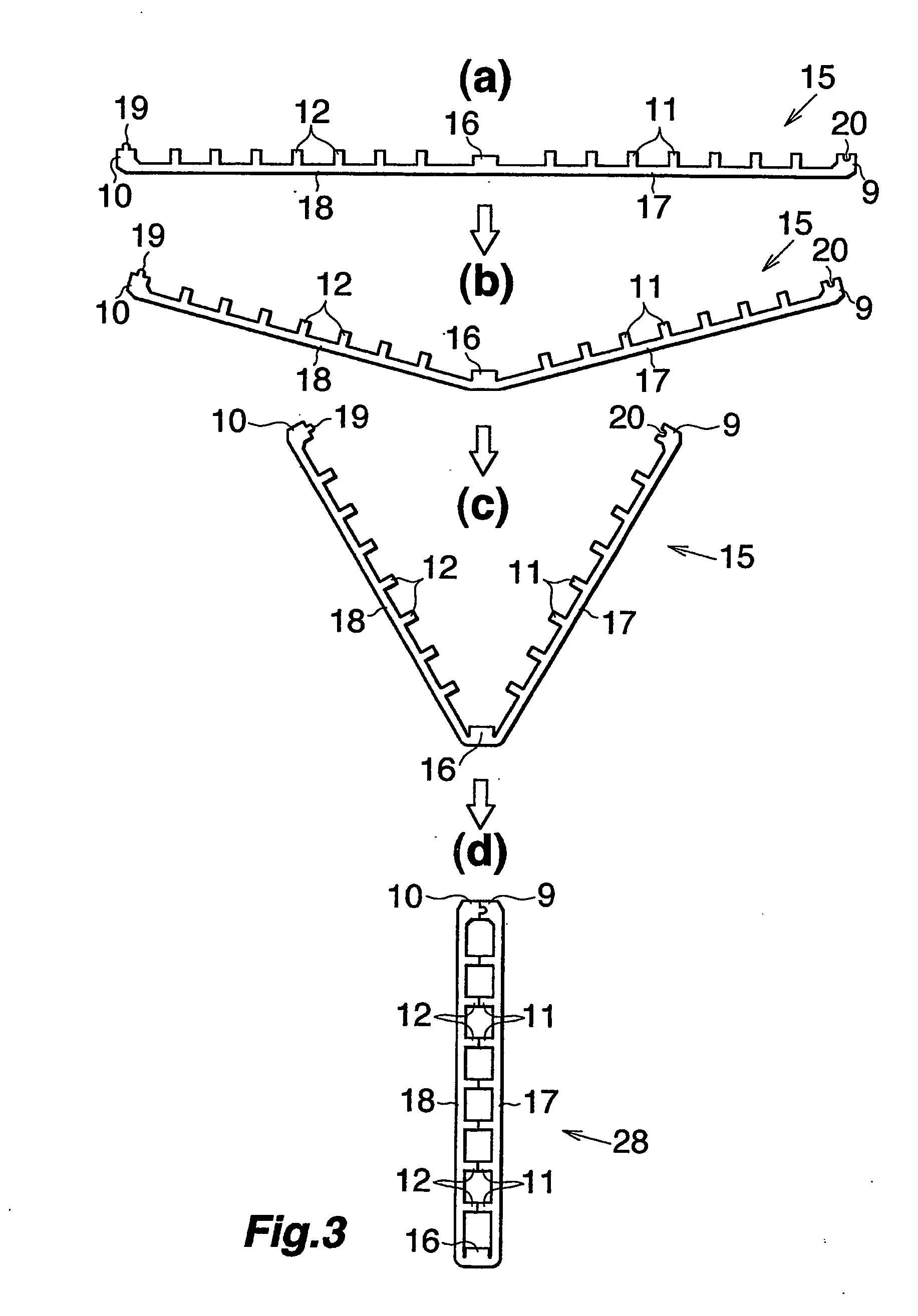

example 1

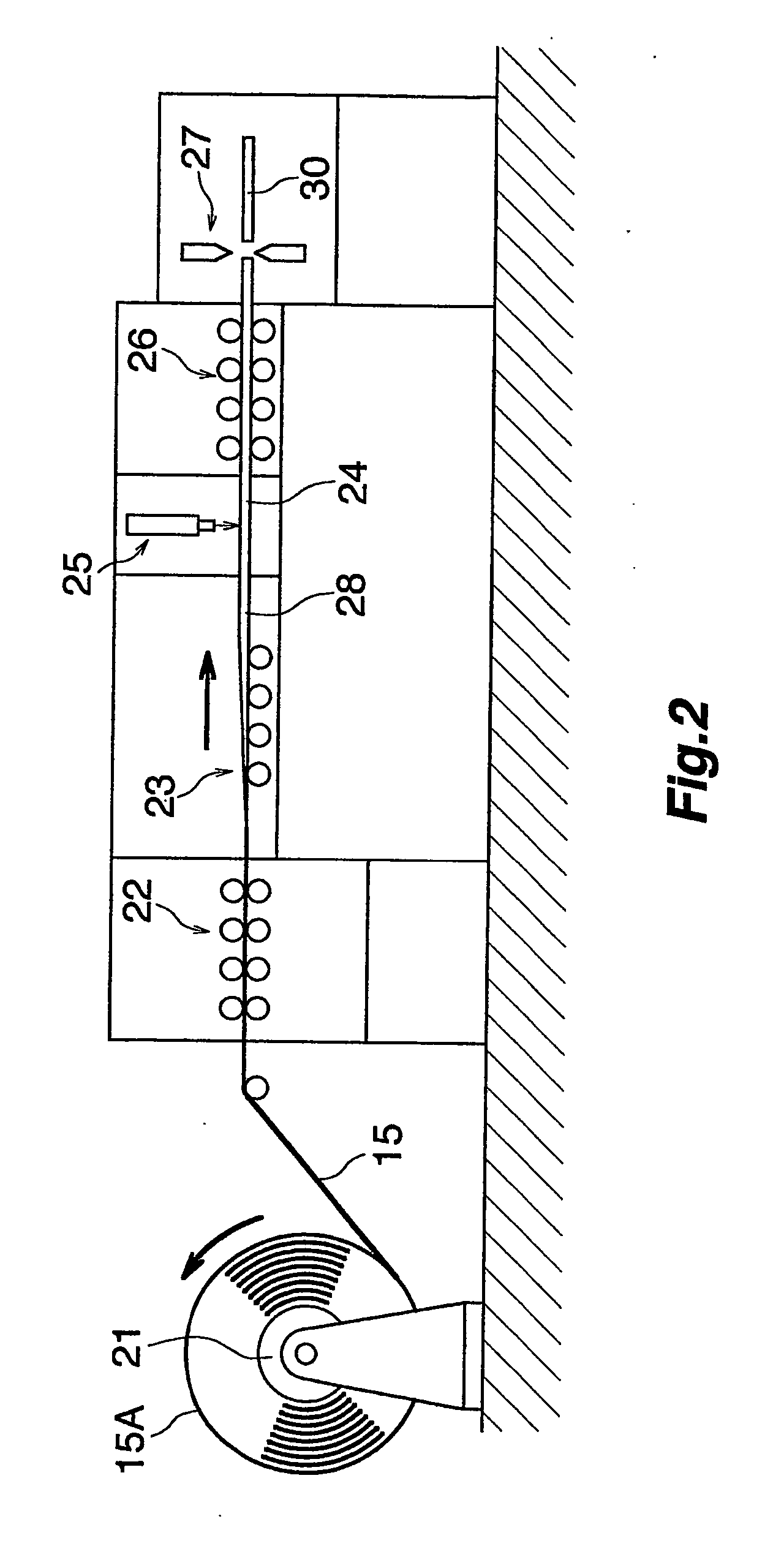

[0069] An aluminum brazing sheet made from JIS BAS211P was rolled into a metal plate 15 shown in FIG. 3, (a). The metal plate was then made into a semifinished flat tube 40 wherein two third portions 9, 10 were continuously joined to each other over the entire length thereof by laser welding as shown in FIG. 7. The laser welding conditions were: pulse width, 0.5 flat tubes 1 may be produced simultaneously with the fabrication of the condenser. More specifically, the condenser is fabricated in the following manner. First prepared are a plurality of semifinished flat tubes 30. Also prepared are a pair of aluminum headers 100, 101 each having semifinished tube inserting holes equal in number to the number of semifinished flat tubes 30, and a plurality of corrugated aluminum fins 103. The pair of headers 100, 101 are then arranged as spaced apart, the semifinished flat tubes 30 and the fins 103 are arranged alternately, and opposite ends of the semifinished flat tubes 30 are inserted in...

examples 2-9

[0072] An aluminum brazing sheet made from JIS BAS211P was rolled into a metal plate 15 shown in FIG. 3, (a). The metal plate was then made into a semifinished flat tube 30 wherein two third portions 9, 10 were intermittently joined to each other at a spacing longitudinally thereof by laser welding as shown in FIGS. 4 to 6. The laser welding conditions were: pulse width, 0.5 ms; frequency, 66.7 Hz; pulse energy, 3 J; assist gas, none; work moving velocity, 200 m / min. The laser welds were 0.6 mm in nugget diameter D and 0.2 mm in the depth of penetration d. The weld laser 31 positioned at each of opposite end portions of the third portions 9, 10 was at a distance L of 15 mm from the longitudinal end of the third portion. The tubes 30 of the examples were produced with varying weld pitches P. The semifinished flat tubes 30 were 1.1 mm in the combined height H of the two third portions 9, 10, 0.4 mm in the thickness t of each of the third portions 9, 10, and 16 mm in the overall width....

examples 10-15

[0075] An aluminum brazing sheet made from JIS BAS211P was rolled into a metal plate 15 shown in FIG. 3, (a). The metal plate was then made into a semifinished flat tube 30 wherein two third portions 9, 10 were intermittently joined to each other at a spacing longitudinally thereof by laser welding as shown in FIGS. 4 to 6. The laser welding conditions were: pulse width, 0.5 ms; frequency, 66.7 Hz; pulse energy, 3 J; assist gas, none; work moving velocity, 200. m / min. The laser weld 31 positioned at each of opposite end portions of the third portions 9, 10 was at a distance L of 15 mm from the longitudinal end of the third portion. The pitch P of all the welds was 30 mm. The tubes 30 of the examples were produced with varying values for D / H ahd for d / t wherein D is the nugget diameter of laser the welds 31, H is the combined height of the two third portions 9, 10, d is the depth of penetration of the laser welds 31, and t is the thickness of each of the third portions 9, 10. The sem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com