Detecting device, detecting method, manufacturing method and pattern transferring method for photomask

An inspection device and inspection method technology, which are applied in the field of photomasks for liquid crystal device manufacturing and inspection devices for large photomasks, can solve the problem that the objective lens system and the movement amount of the object to be exposed cannot be simulated quantitatively and cannot be reproduced correctly. Exposure device focusing action exposure pattern, can not be simulated quantitatively, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

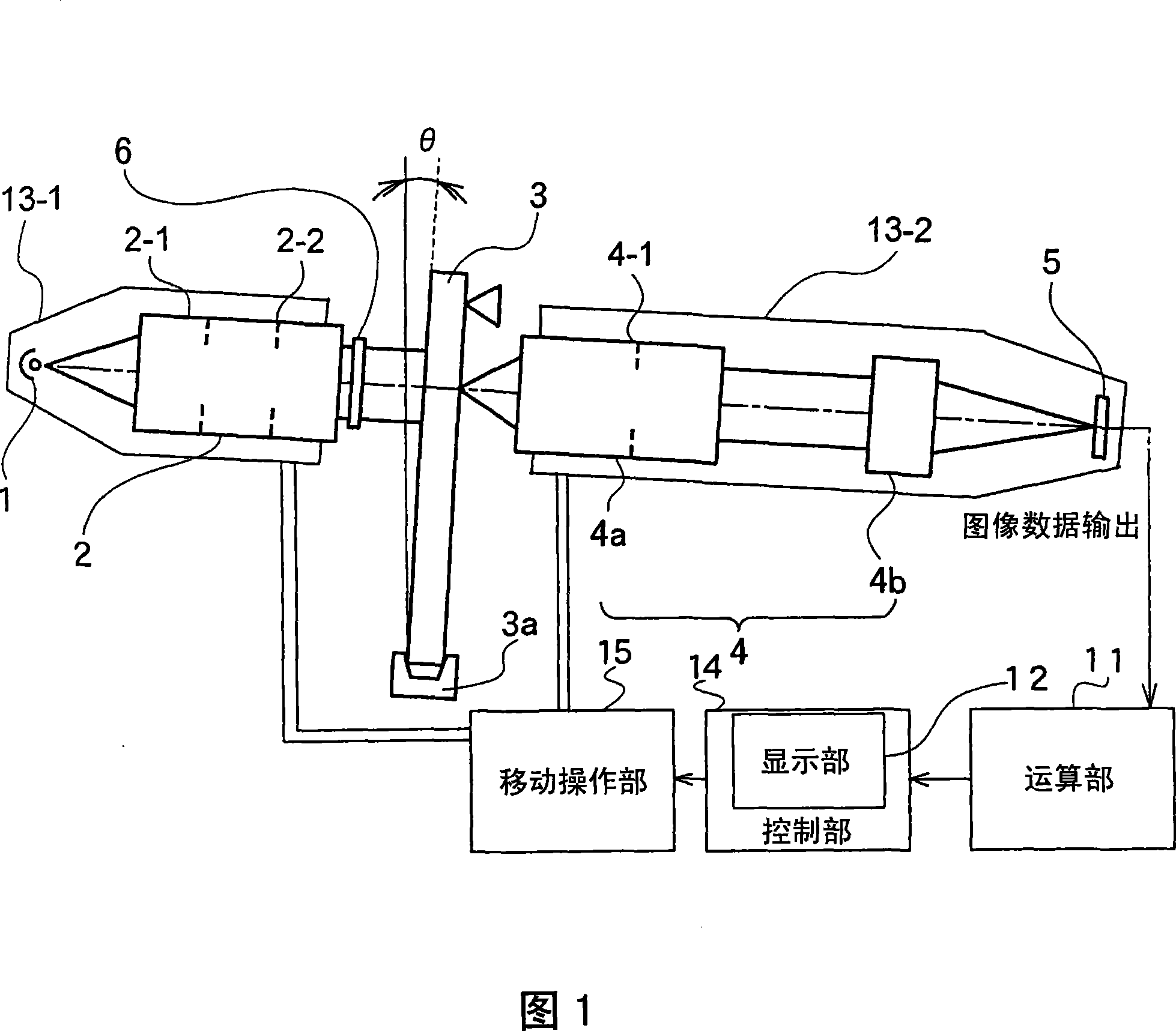

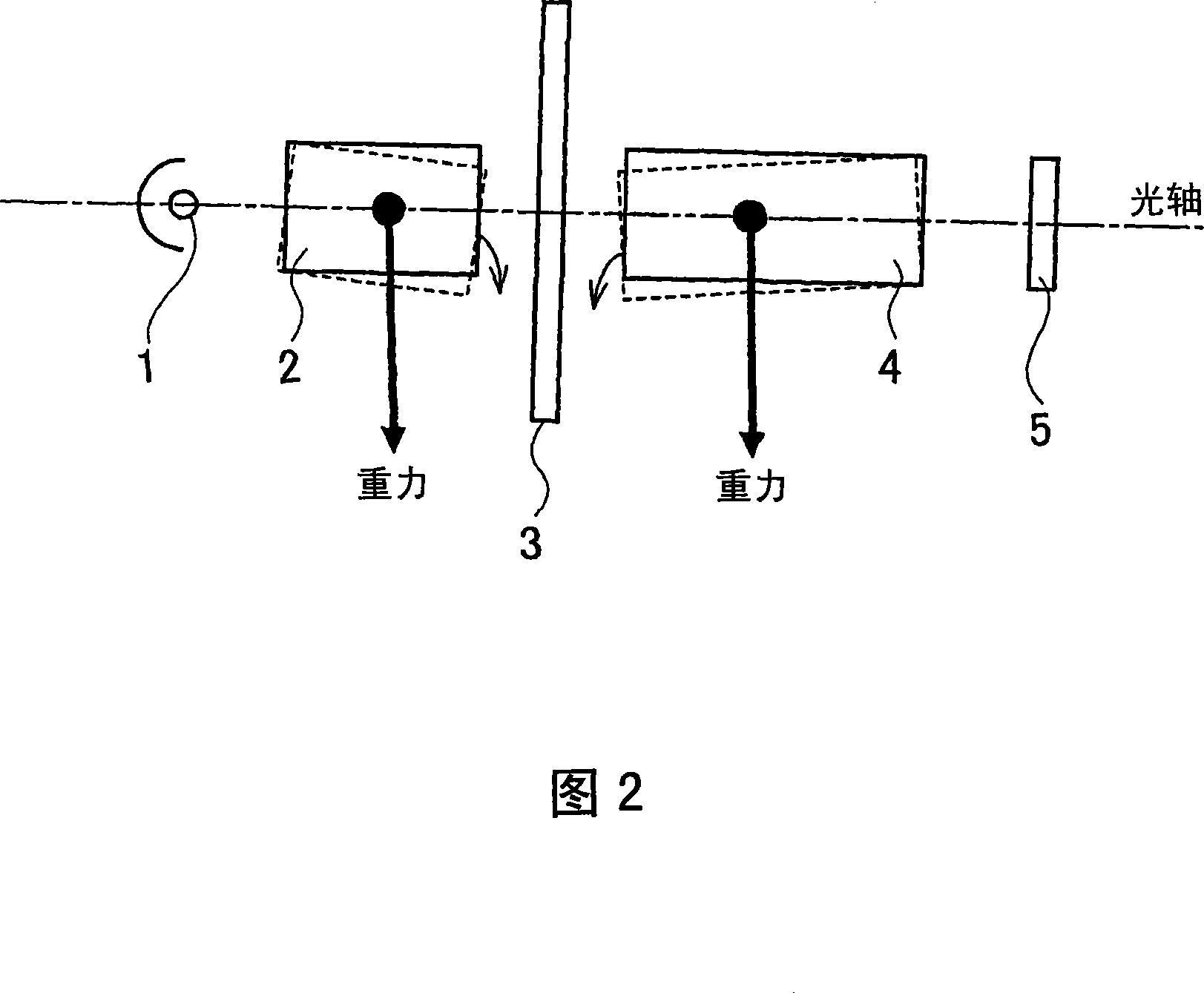

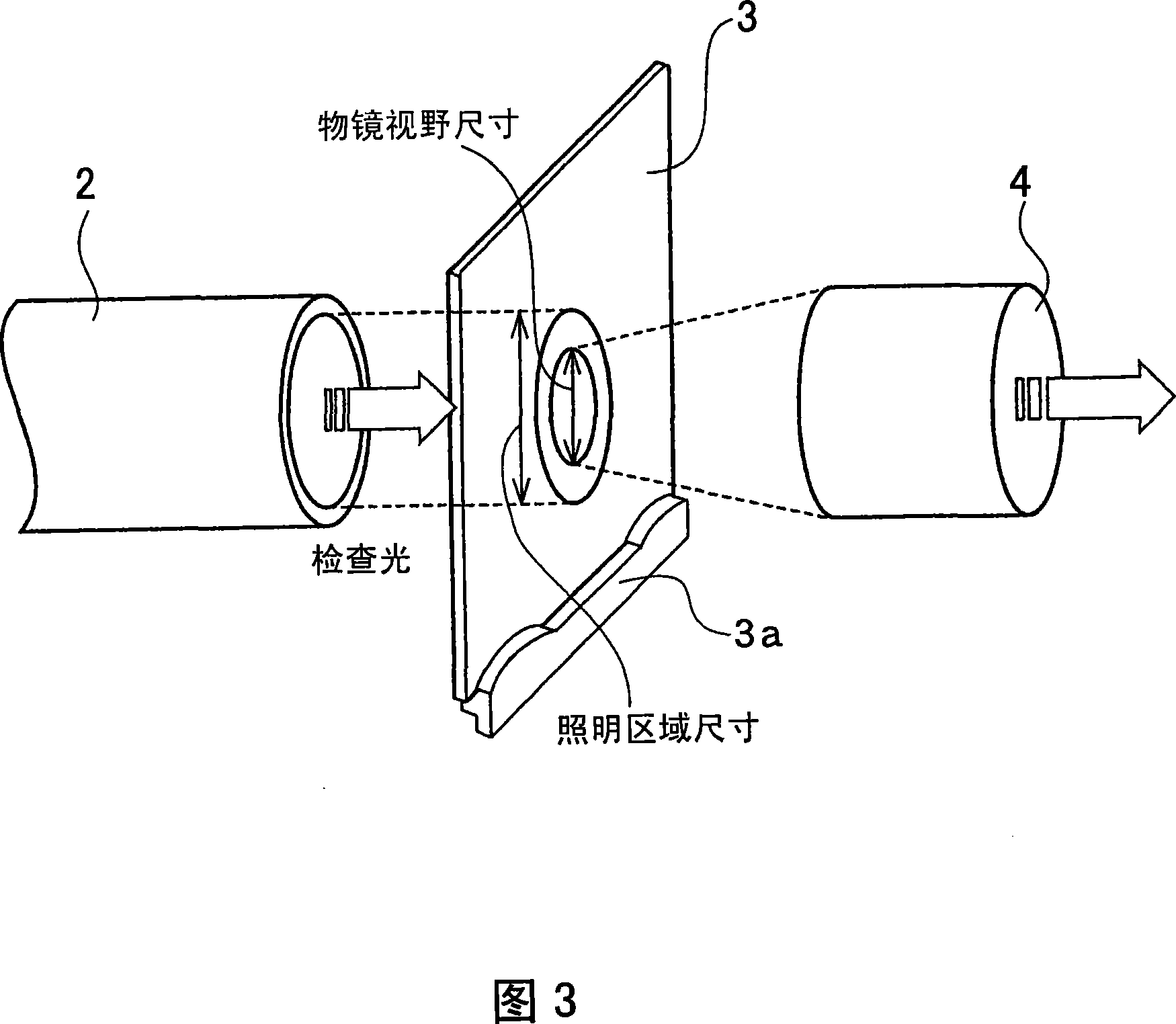

[0126] Next, the best mode for carrying out the present invention will be described.

[0127] [Summary of the photomask inspection device of the present invention]

[0128] The photomask inspection device of the present invention is a device that can perform exposure conditions equal to those in an exposure device that performs exposure by using a photomask made of a transparent substrate, or according to the exposure device The exposure conditions obtained by simulating the exposure by the exposure device are transcribed onto the transcribed image, captured by the imaging unit, and obtained as light intensity distribution data. The exposure device is a device that transcribes the pattern formed in the photomask onto the transcribed body under certain exposure conditions. In addition, a target to be transcribed is, for example, a glass substrate coated with a resist or the like.

[0129] In addition, in this photomask inspection device, based on the light intensity distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com