Piezoelectric vibration generating set and manufacturing method thereof

A technology of vibration power generation and manufacturing method, applied in the field of micro-energy, can solve the problems of unstable quality, poor assembly accuracy and high assembly cost, and achieve the effects of reducing production cost, simple structure and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. The manufacturing method of the piezoelectric vibration power generation device provided by the present invention is convenient for accurate alignment during the assembly production process, thereby improving the assembly accuracy, and greatly improving the production efficiency in batch production, thereby reducing the production cost.

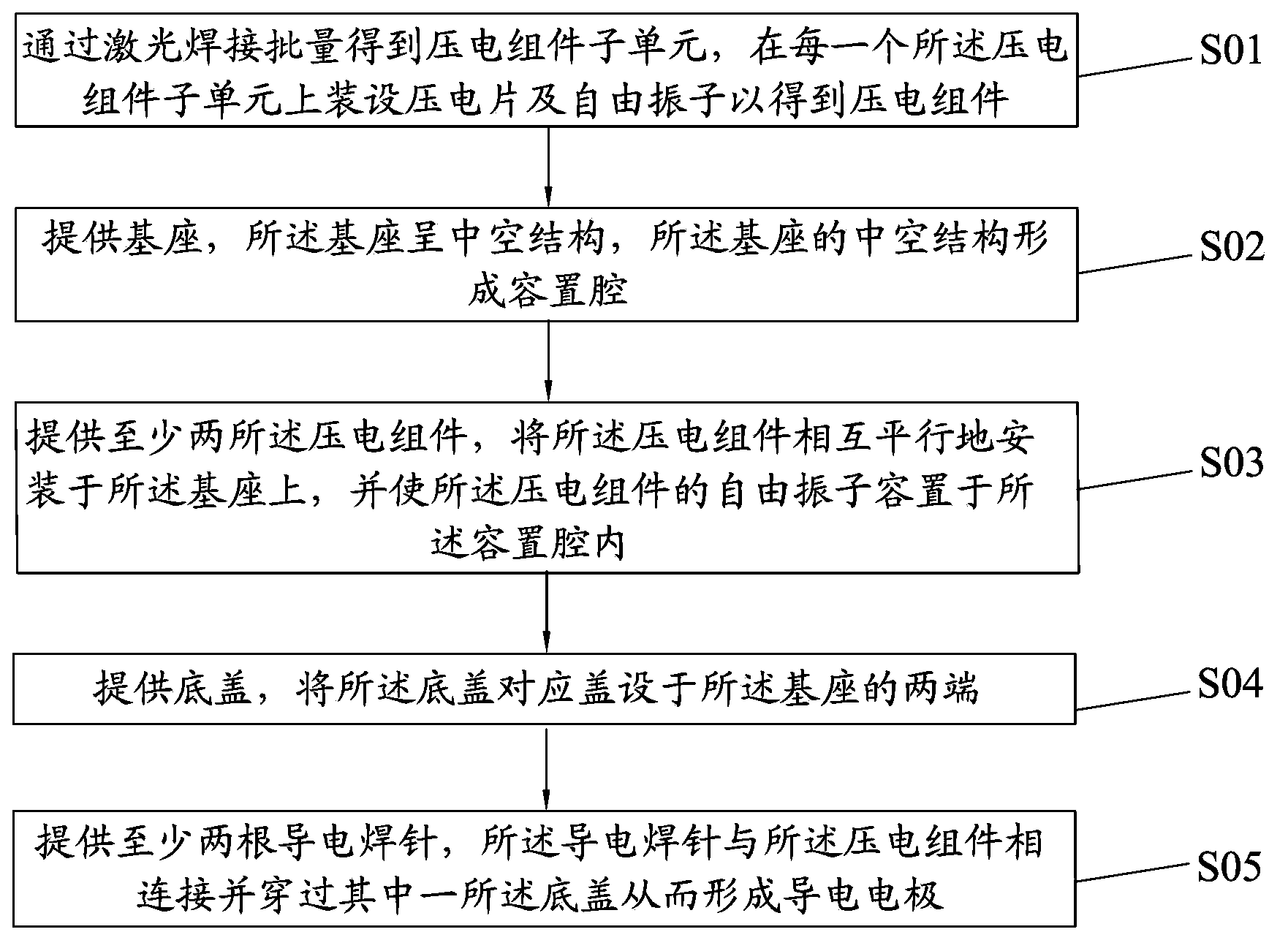

[0037] Such as figure 1 As shown, the manufacturing method of the piezoelectric vibration generating device provided by the present invention comprises the following steps:

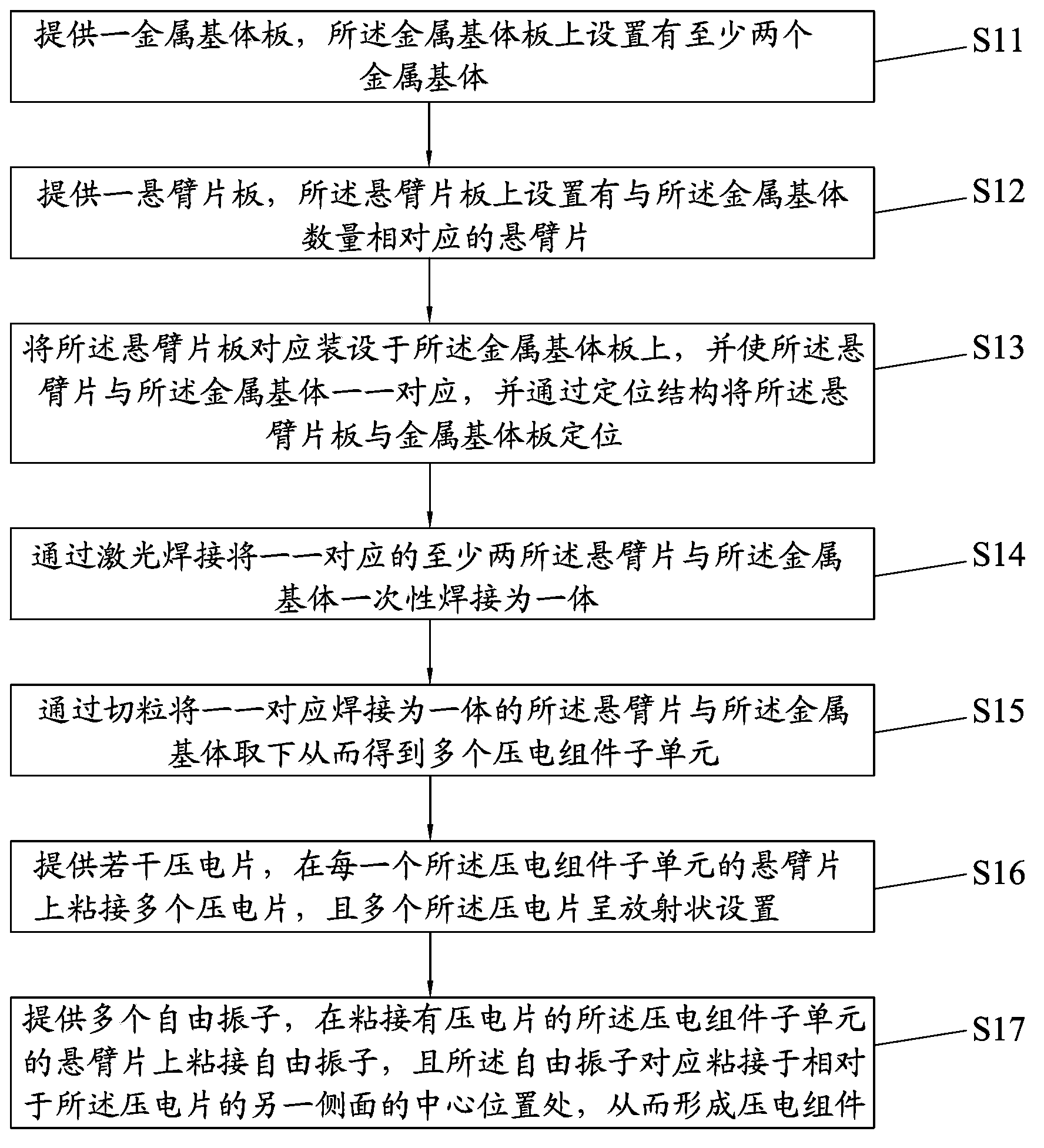

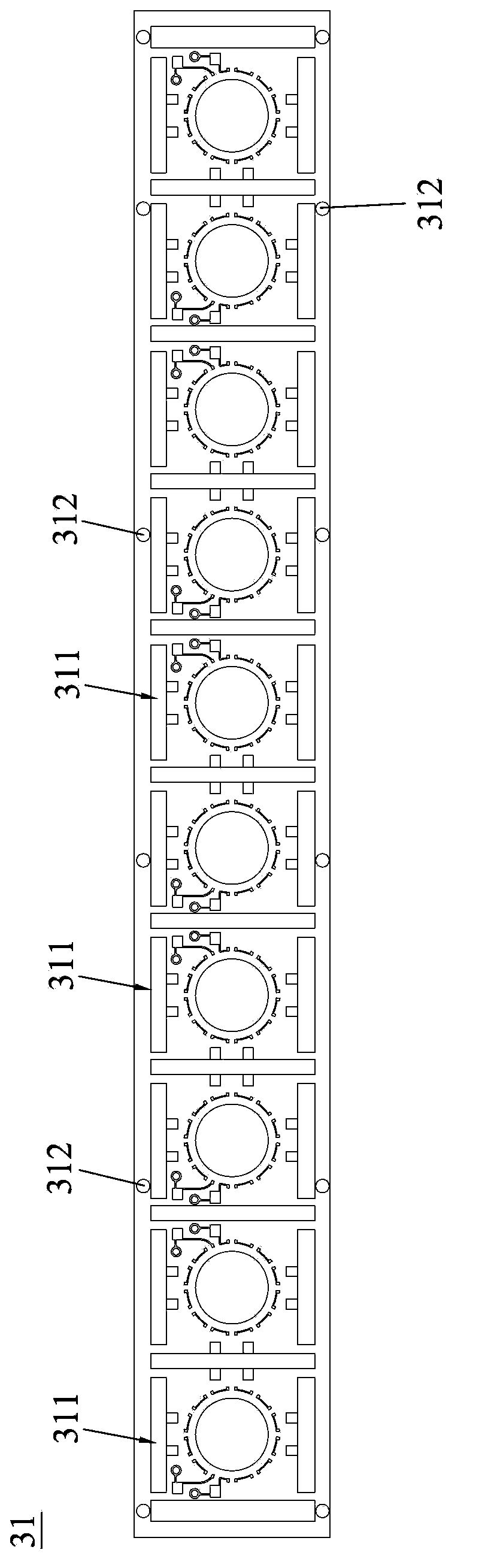

[0038] S01: Obtain piezoelectric component subunits in batches by laser welding, and install piezoelectric sheets and free oscillators on each of the piezoelectric component subunits to obtain piezoelectric components;

[0039]S02: Provide a base, the base has a hollow structure, and the hollow structure of the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com