Electric die-casting machine with core-riving hydraulic unit

A hydraulic unit and die-casting machine technology, applied in the field of electric die-casting machines, can solve the problems of inability to share hydraulic units for core driving, low output grid, etc., achieve easy movement and storage, prevent the increase of installation area, easy installation and removed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

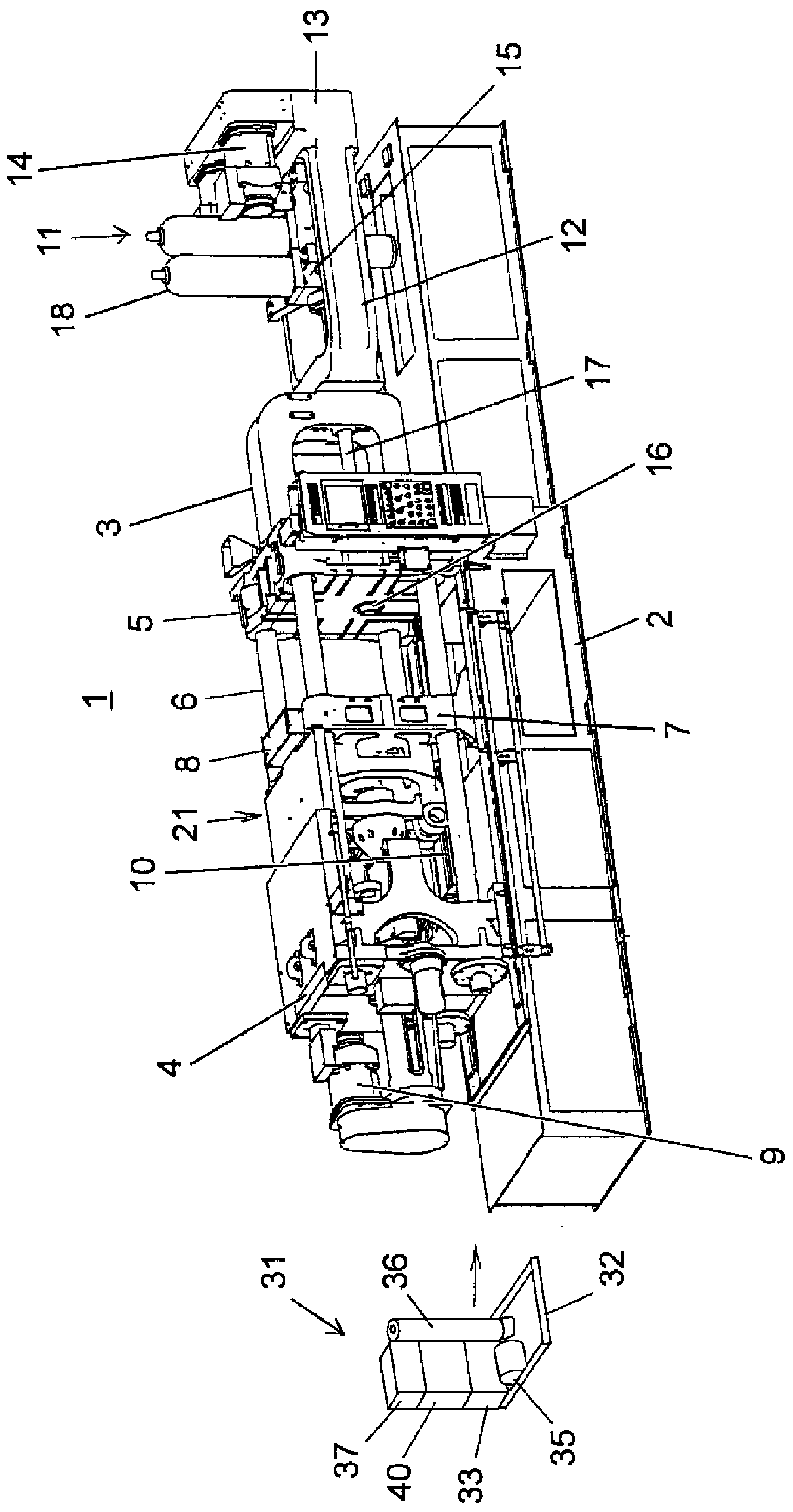

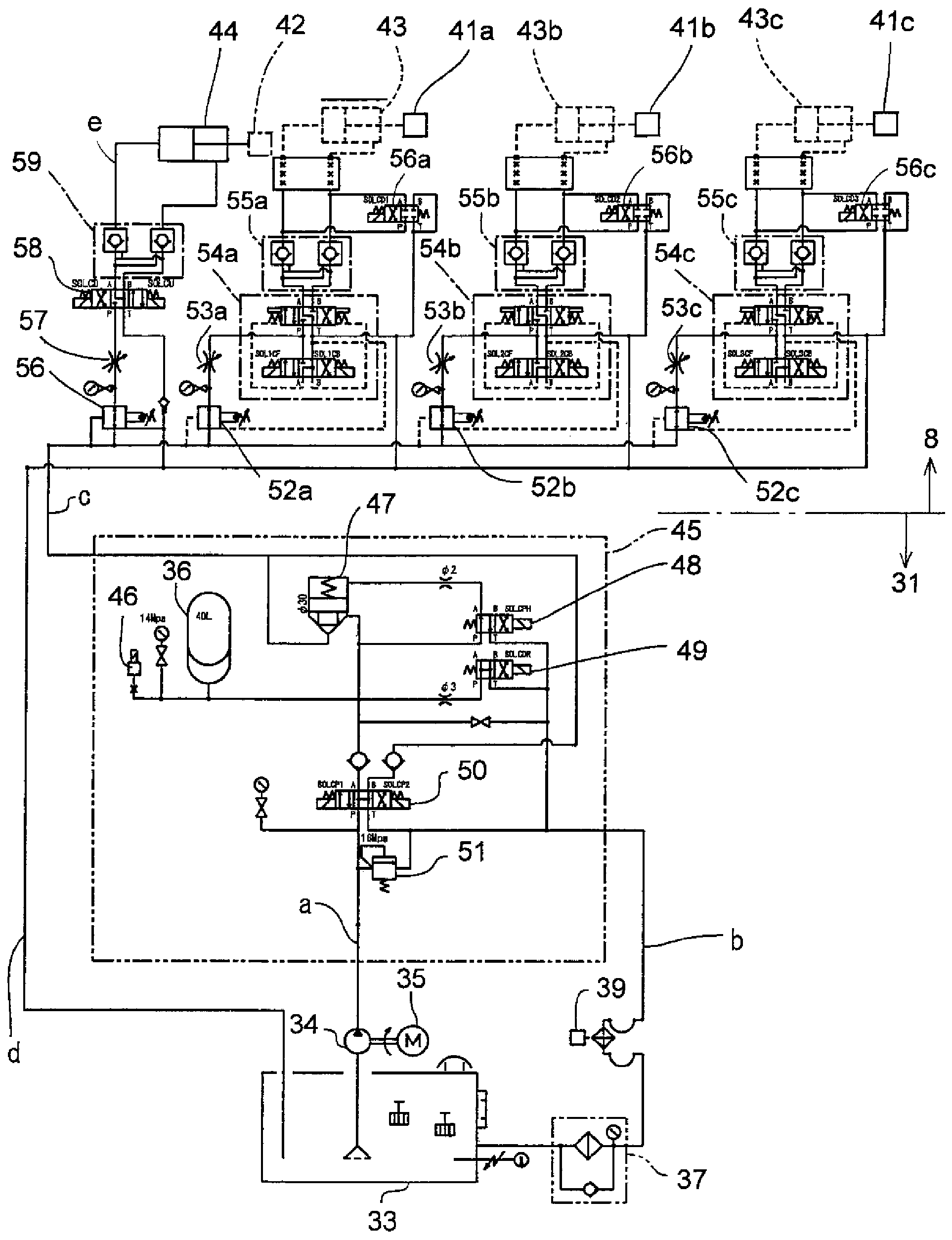

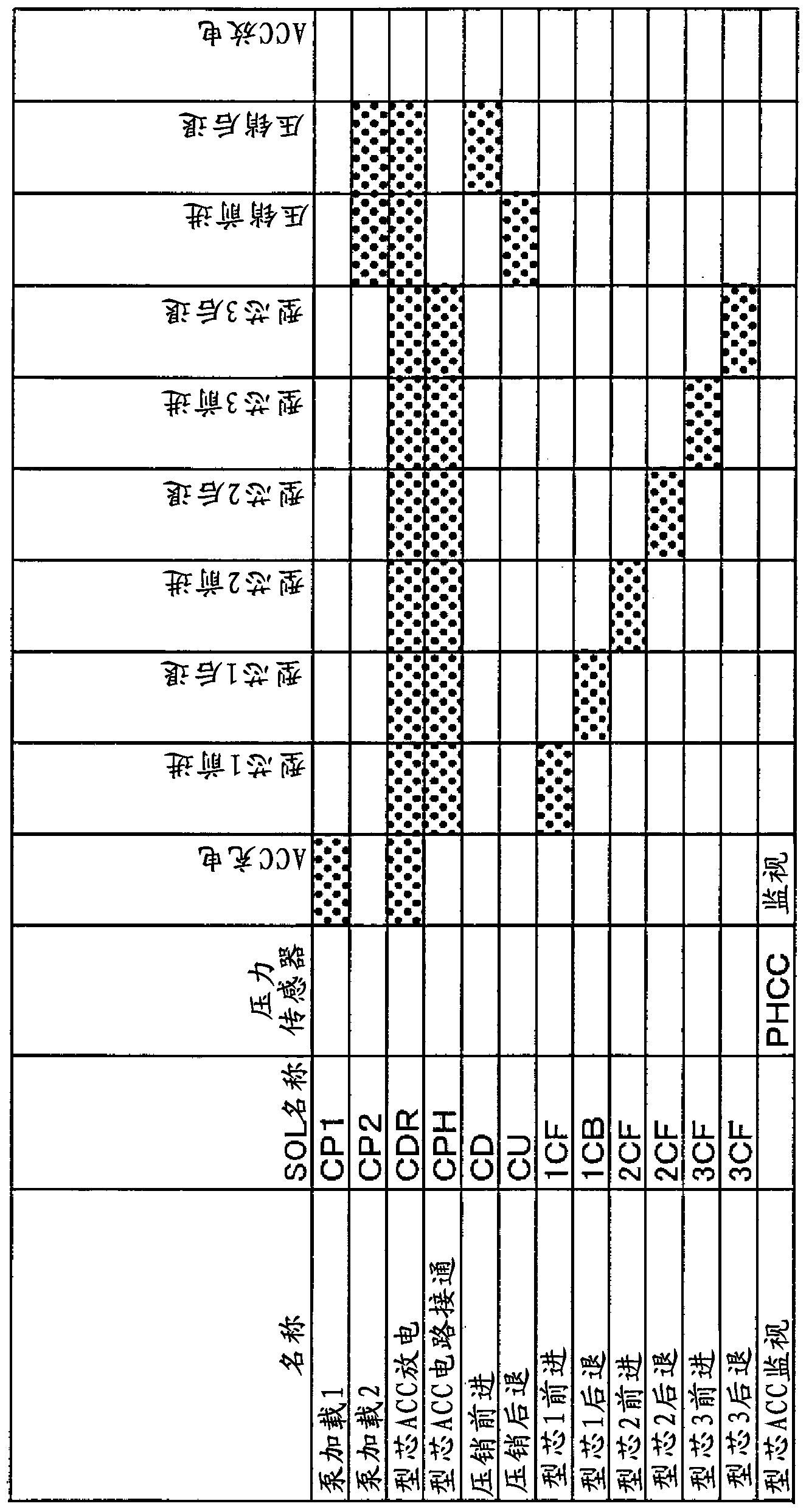

[0032] Next, an embodiment of an electric die-casting machine including a core-driving hydraulic unit according to the present invention will be described with reference to the drawings.

[0033] Such as figure 1 As shown, the electric die-casting machine 1 of this embodiment mainly includes a main base plate 2, a mold clamping unit 21 installed on the main base plate 2, an injection unit 11 held by the main base plate 2 and the mold clamping unit 21, and a A mold not shown on the mold clamping unit 21 and a hydraulic cylinder for driving a core of the mold (refer to figure 2 ), the core unit 8 installed on the mold clamping unit 21 , and the core driving hydraulic unit 31 detachably installed on the main base plate 2 .

[0034] A set of molds consisting of a fixed mold and a movable mold can be provided with a specified number of cores with a specified shape and size. By assembling the cores, a specified shape corresponding to the appearance shape of the product is formed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com