Piezoelectric vibration generating set and manufacturing method thereof

A technology of vibration power generation and piezoelectricity, which is applied in the field of micro energy, can solve the problems of increasing production cost and installation cost, limited deformation of piezoelectric sheets, and affecting power generation efficiency, etc., and achieves high mechanical energy conversion efficiency, improved power generation efficiency, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

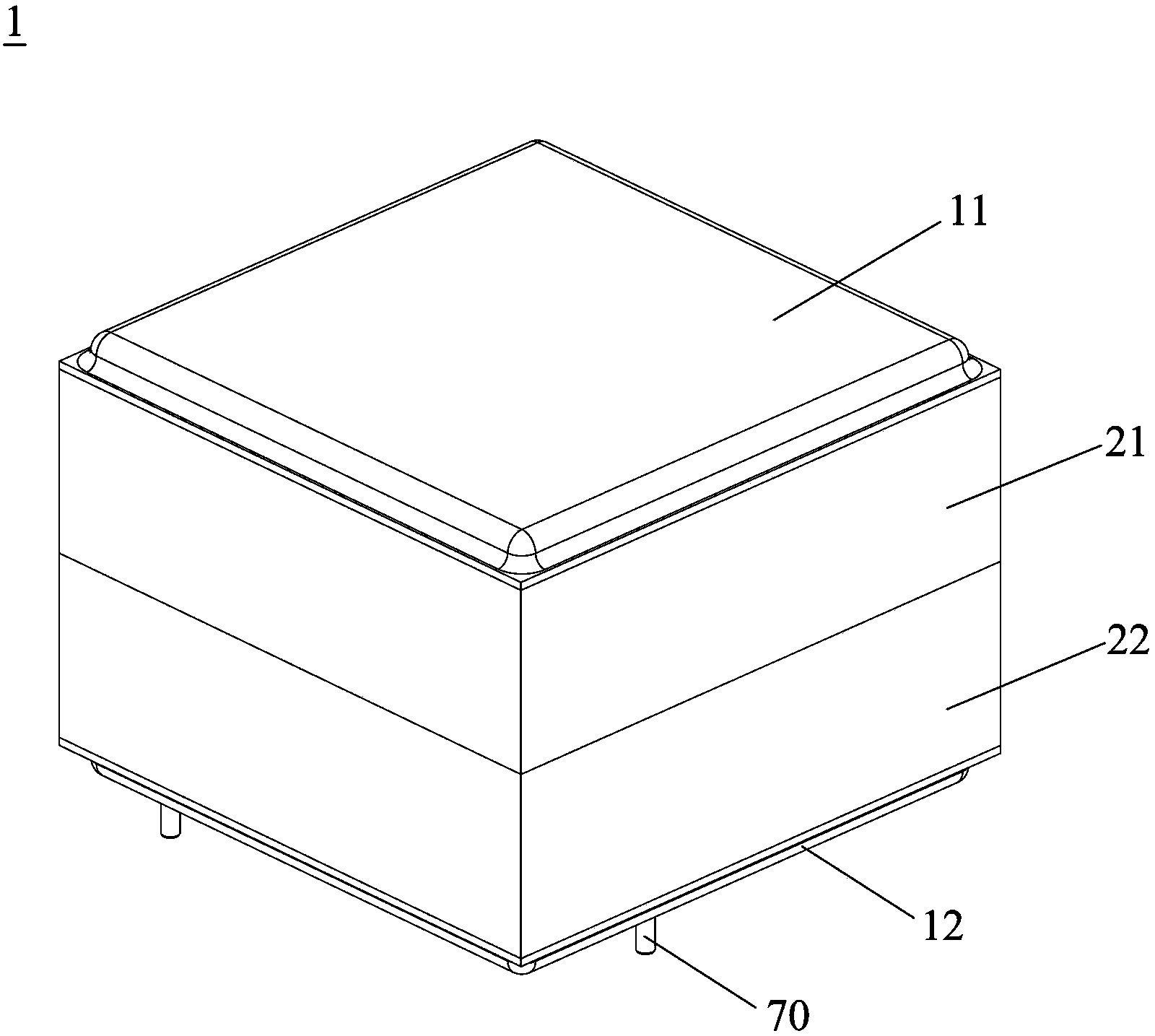

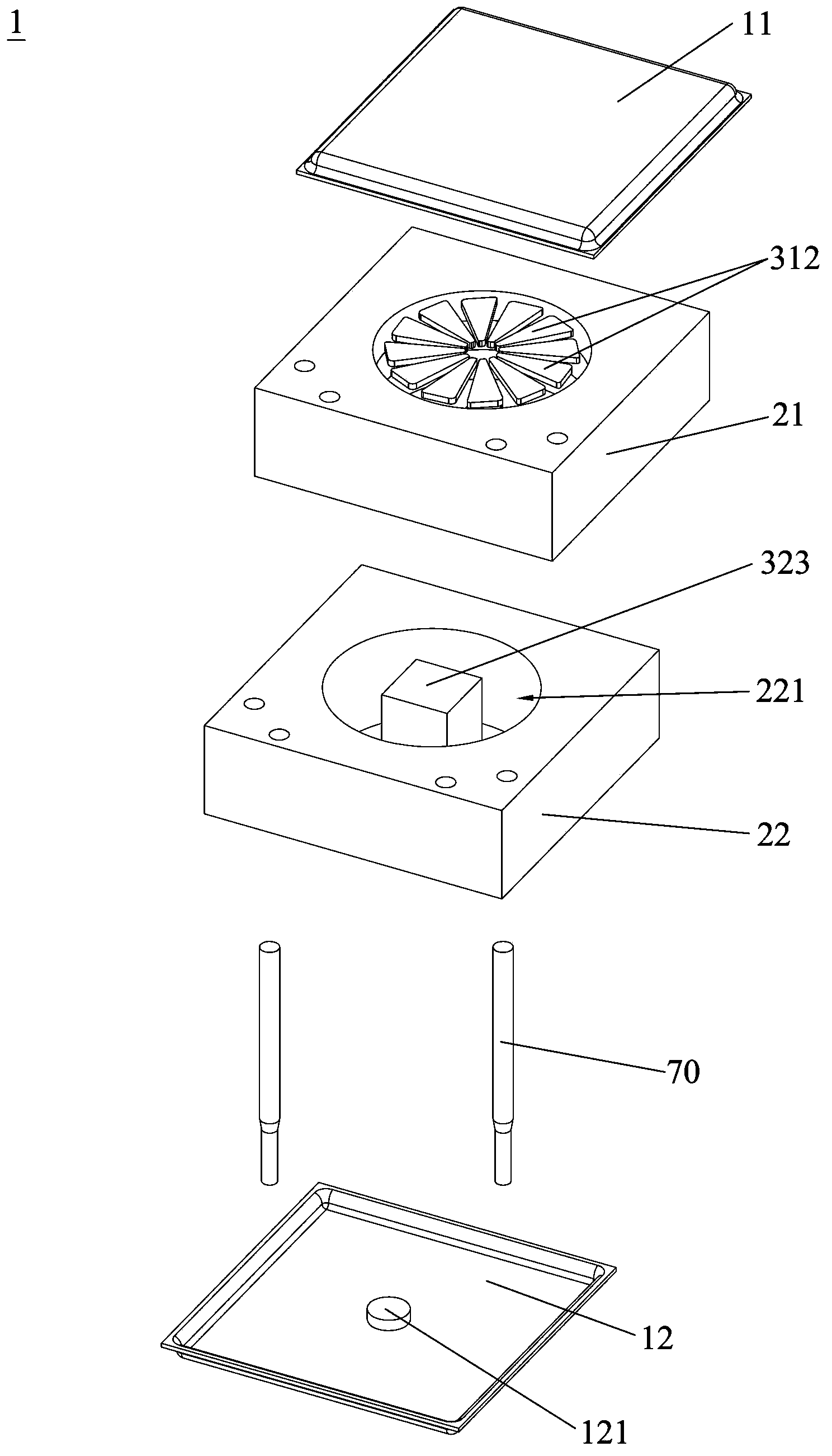

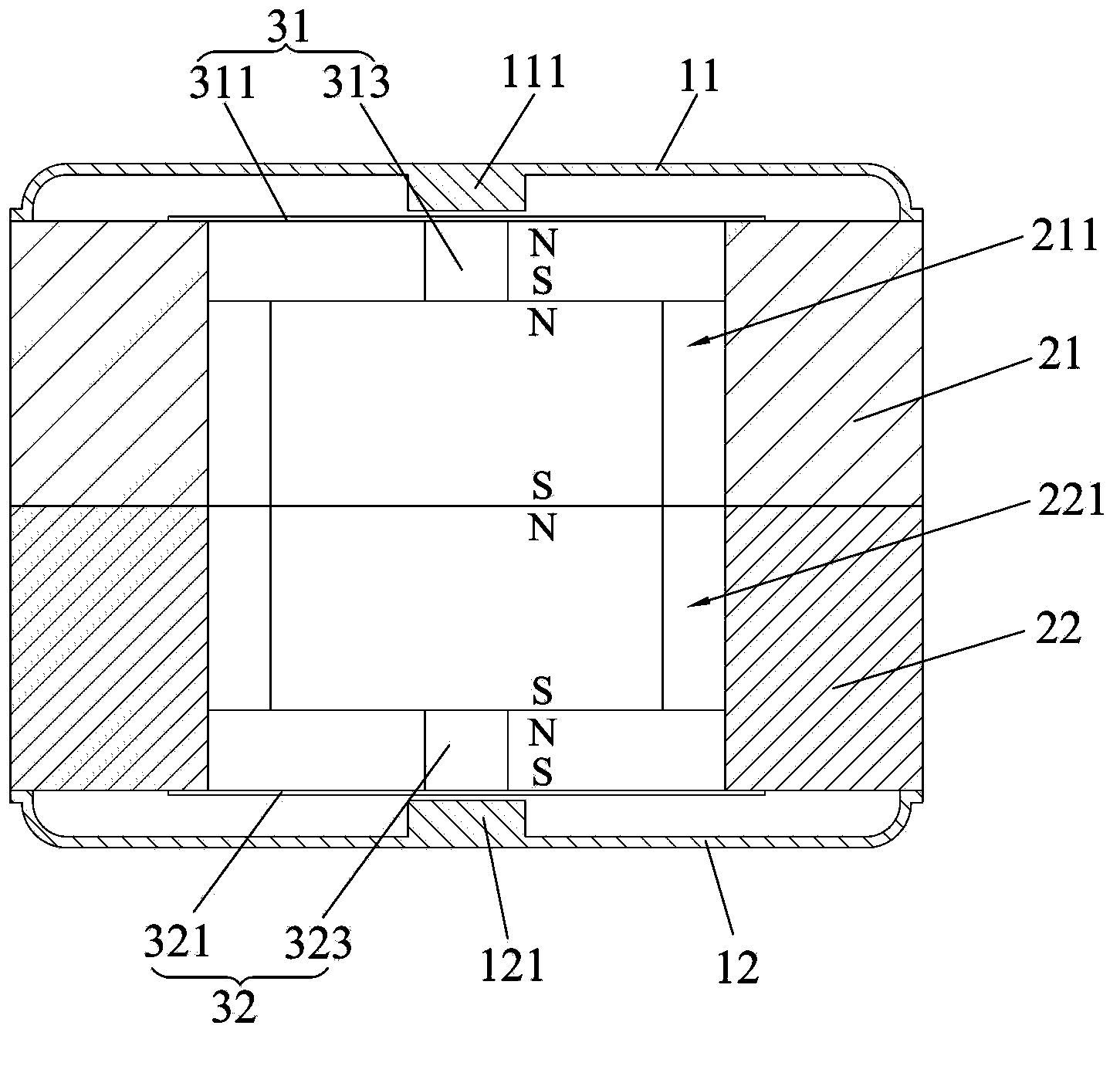

[0043] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. The piezoelectric vibration power generation device 1 of the present invention includes a bottom cover, a base, at least two power generating units and at least two conductive welding pins. The power generation unit is arranged on the base and parallel to each other, and the two bottom covers are respectively provided on two ends of the base, and the two bottom covers seal the accommodating cavity. Wherein, the base can be one, or a plurality of correspondingly connected structures.

[0044] Combine below Figure 1-Figure 12 As shown, different embodiments of the piezoelectric vibration power generation device 1 of the present invention are described respectively.

[0045] Such as Figure 1-Figure 3 As shown, in the first embodiment of the piezoelectric vibration power generation device 1 of the present invention, the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com