Vacuum heat insulating material and refrigerator

A technology of vacuum heat insulation materials and refrigerators, applied in the direction of heat insulation protection pipelines, heat exchange equipment, lighting and heating equipment, etc., can solve problems such as low heat insulation performance, and achieve the effect of expanding the installation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

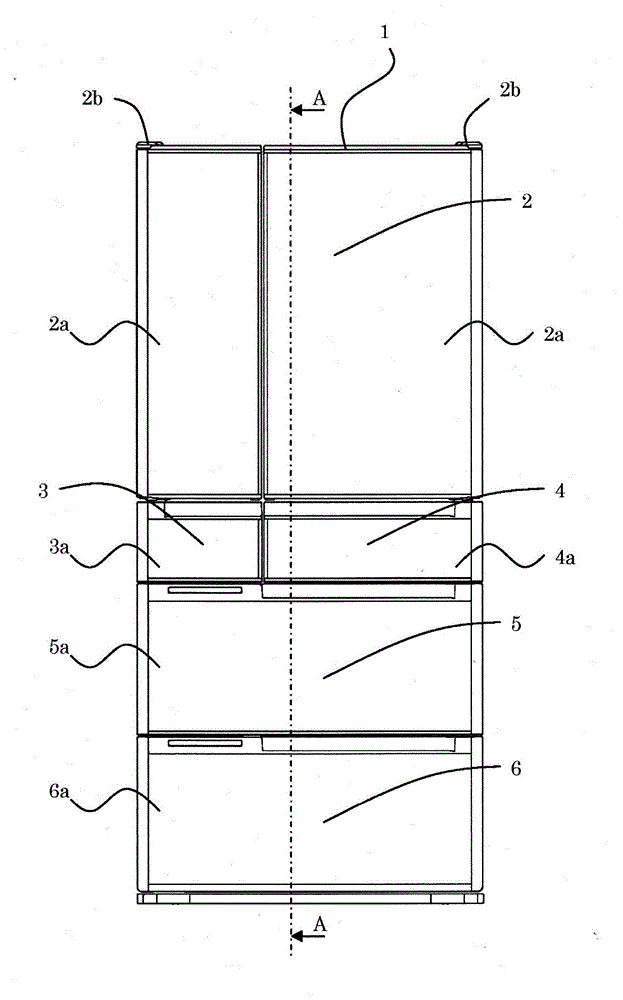

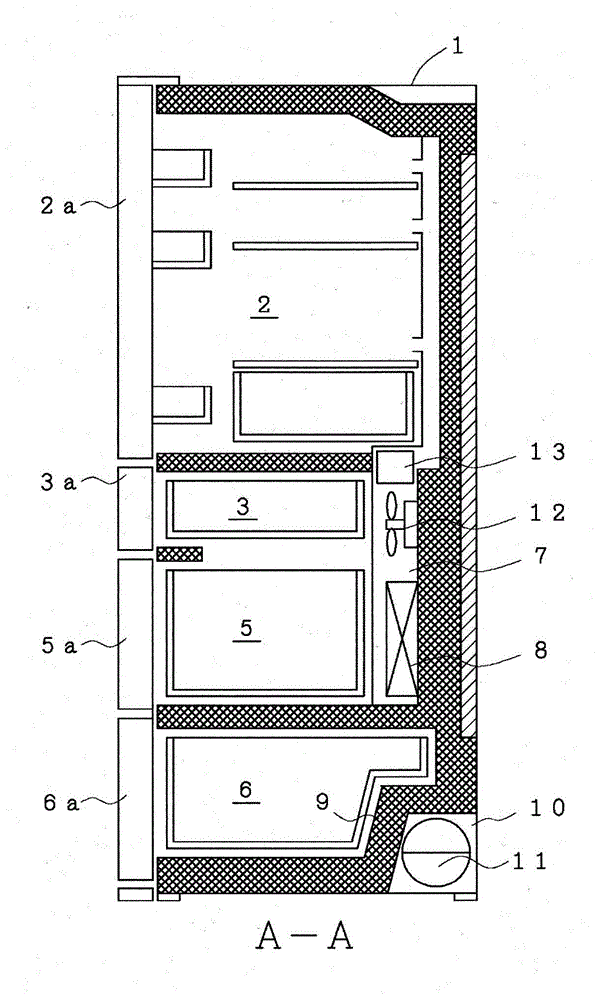

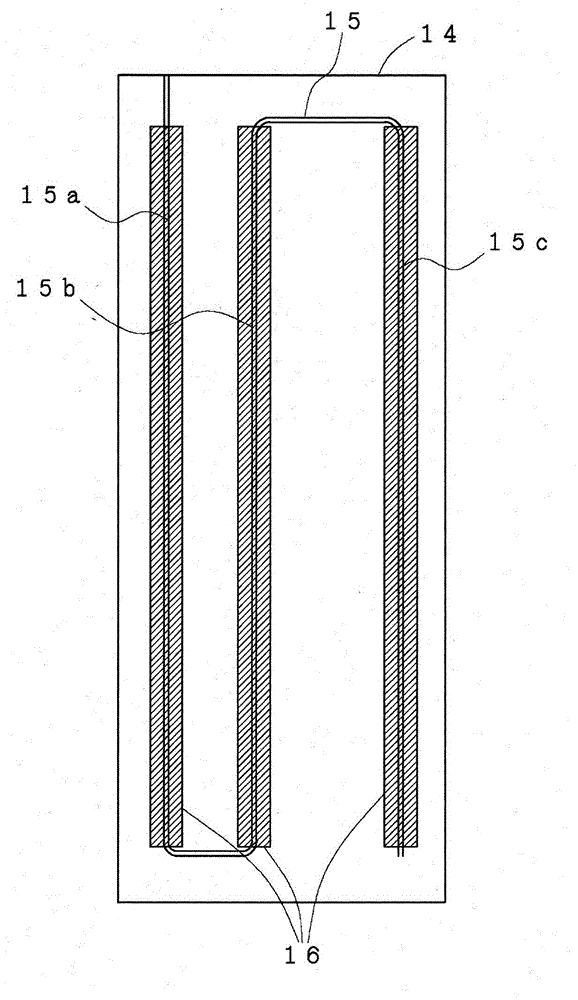

[0029] figure 1 It is a front view of the refrigerator which concerns on Example of this invention. figure 2 yes figure 1 A-A cutaway view.

[0030] exist figure 1 In the refrigerator main body 1, a refrigerator compartment 2, an ice-making compartment 3, a second freezer compartment 4, a first freezer compartment 5, and a vegetable compartment 6 arranged laterally side by side with the ice-maker compartment 3 are arranged in sequence from top to bottom as storage compartments. . Moreover, the doors 2a, 3a, 4a, 5a, 6a for closing the front opening are attached to each of these storage rooms, respectively. The left and right refrigerator compartment doors 2a that close the front opening of the refrigerator compartment 2 are French doors held by hinges 2b so as to be individually rotatable and openable. The other doors 3a, 4a, 5a, and 6a are pull-out doors that move in the front-rear direction and close the openings of the respective storage compartments.

[0031] exist ...

Embodiment 2

[0060] Image 6 It is a partial enlarged sectional view of the heat insulating wall of Example 2.

[0061] exist Image 6 In the space 18 formed between the outer box 14 and the inner box 17, the first vacuum insulation material 19 and the foam insulation material 21 are filled. This vacuum heat insulating material 19 is formed by putting the core material 22 and an adsorbent in a bag-shaped covering material 23 , vacuumizing the inside of the covering material 23 , and sealing it.

[0062] The fiber aggregate 22 is comprised by three layers of the 1st fiber aggregate 22a, the 2nd fiber aggregate 22b, and the 3rd fiber aggregate 22c. The second fiber aggregate 22b is longer than the first fiber aggregate 22a and the third fiber aggregate 22c, and the third fiber aggregate 22c is shorter than the first fiber aggregate 22a. The second groove 19b and the third groove 19c (as Figure 4 shown) is formed by pressing the evacuated first vacuum heat insulating material 19 with a m...

Embodiment 3

[0067] Figure 7 It is a partial enlarged sectional view of the heat insulating wall of Example 3.

[0068] exist Figure 7 In the space 18 formed between the outer box 14 and the inner box 17, the first vacuum insulation material 19 and the foam insulation material 21 are filled. This vacuum heat insulating material 19 is formed by putting the core material 22 and an adsorbent in a bag-shaped covering material 23 , vacuumizing the inside of the covering material 23 , and sealing it.

[0069] The fiber aggregate 22 is comprised by three layers of the 1st fiber aggregate 22a, the 2nd fiber aggregate 22b, and the 3rd fiber aggregate 22c. The first fiber aggregate 22a and the second fiber aggregate 22b have the same length and width. On the other hand, the third fiber aggregate 22c is shorter in width than the first and second fiber aggregates 22a and 22b. The second groove 19b and the third groove 19c (as Figure 4 shown) is formed by pressing the evacuated first vacuum hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com