Sheet application device and application method

A technology for sticking devices and sheets, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc. It can solve the problems of increased risk of wafers and adhesive sheets, easy to fall on wafers, etc., to reduce risks and suppress settings The effect of increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 〕

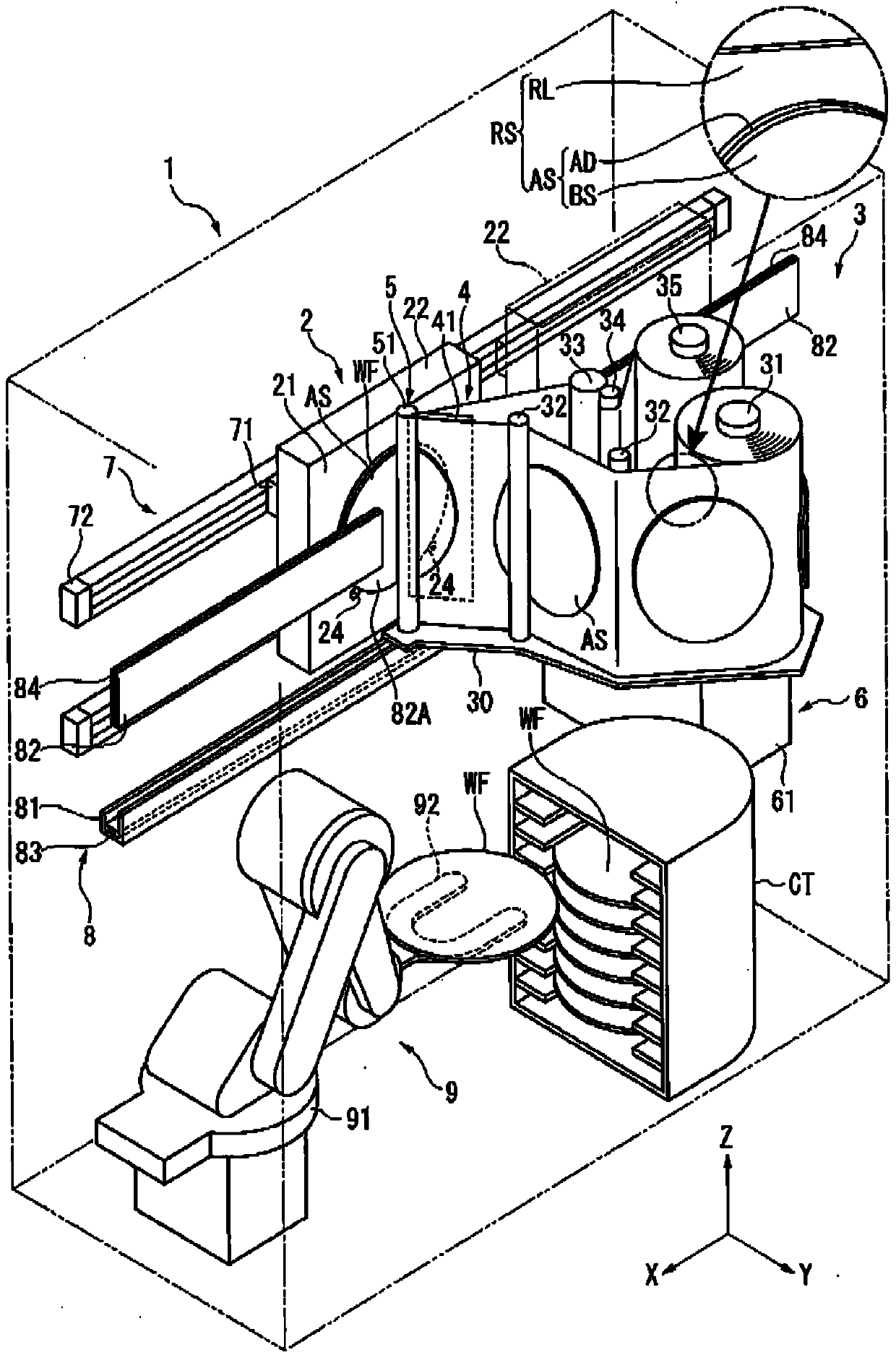

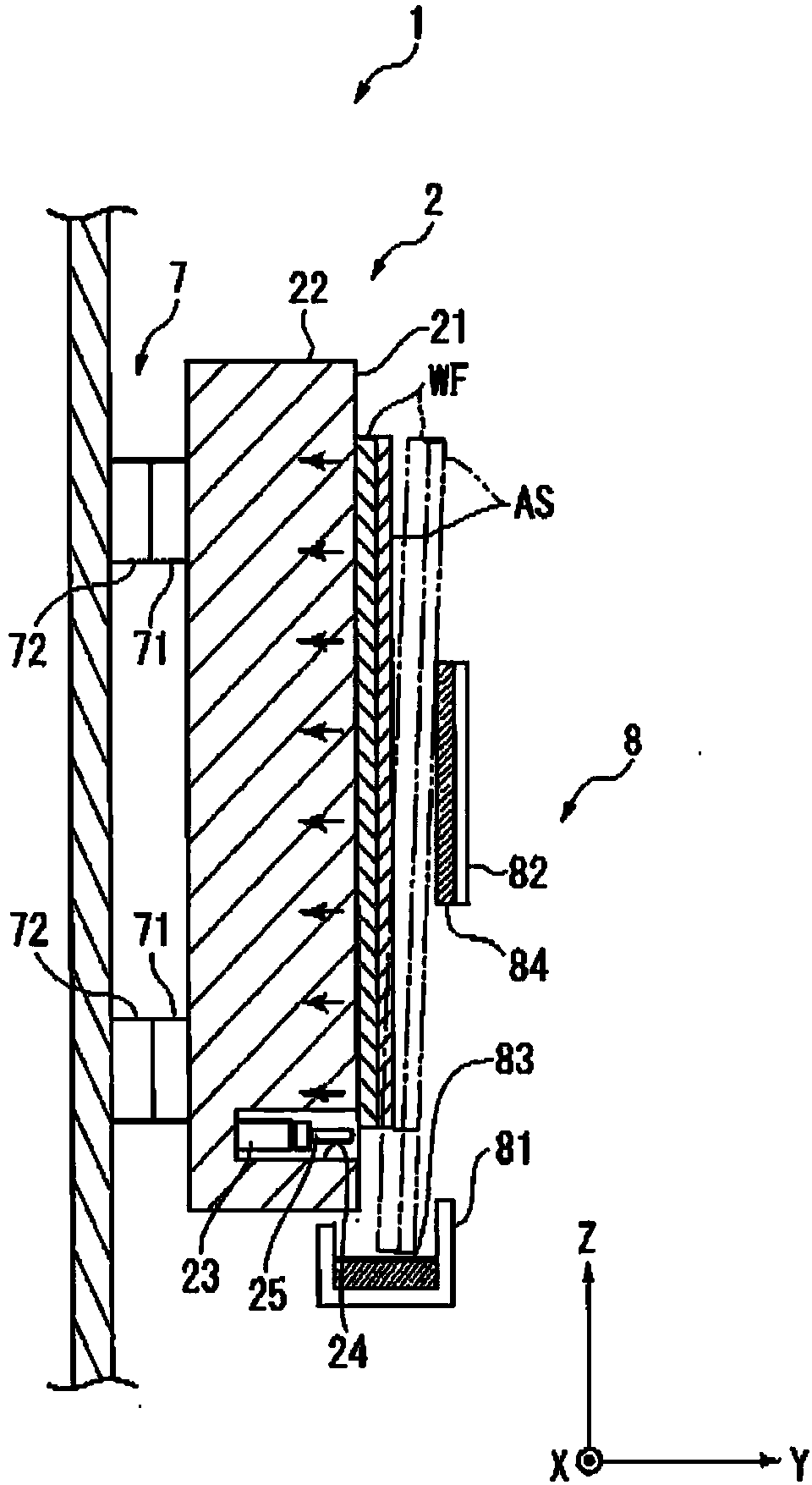

[0048] exist figure 1 Among them, the sheet sticking device 1 is a device for sticking an adhesive sheet AS on a wafer WF which is a plate-shaped member. Here, the adhesive sheet AS has an adhesive layer AD on one side of the base sheet BS, and is cut in advance into an outer shape of a predetermined size, and is temporarily attached to the tape-shaped release sheet RL via the adhesive layer AD. It is prepared in advance as the roll material RS of the object to be extracted.

[0049] The sheet sticking device 1 is provided with: a supporting device 2 for supporting the wafer WF; a drawing-out device 3 for drawing out the roll material RS; a peeling device 4 for peeling the adhesive sheet AS from the peeling sheet RL of the rolled-out material RS; A pressing device 5 for pressing the peeled adhesive sheet AS against the wafer WF; a sheet positioning device 6 as a second positioning device for positioning the adhesive sheet AS relative to the wafer WF; and making the support de...

no. 2 approach 〕

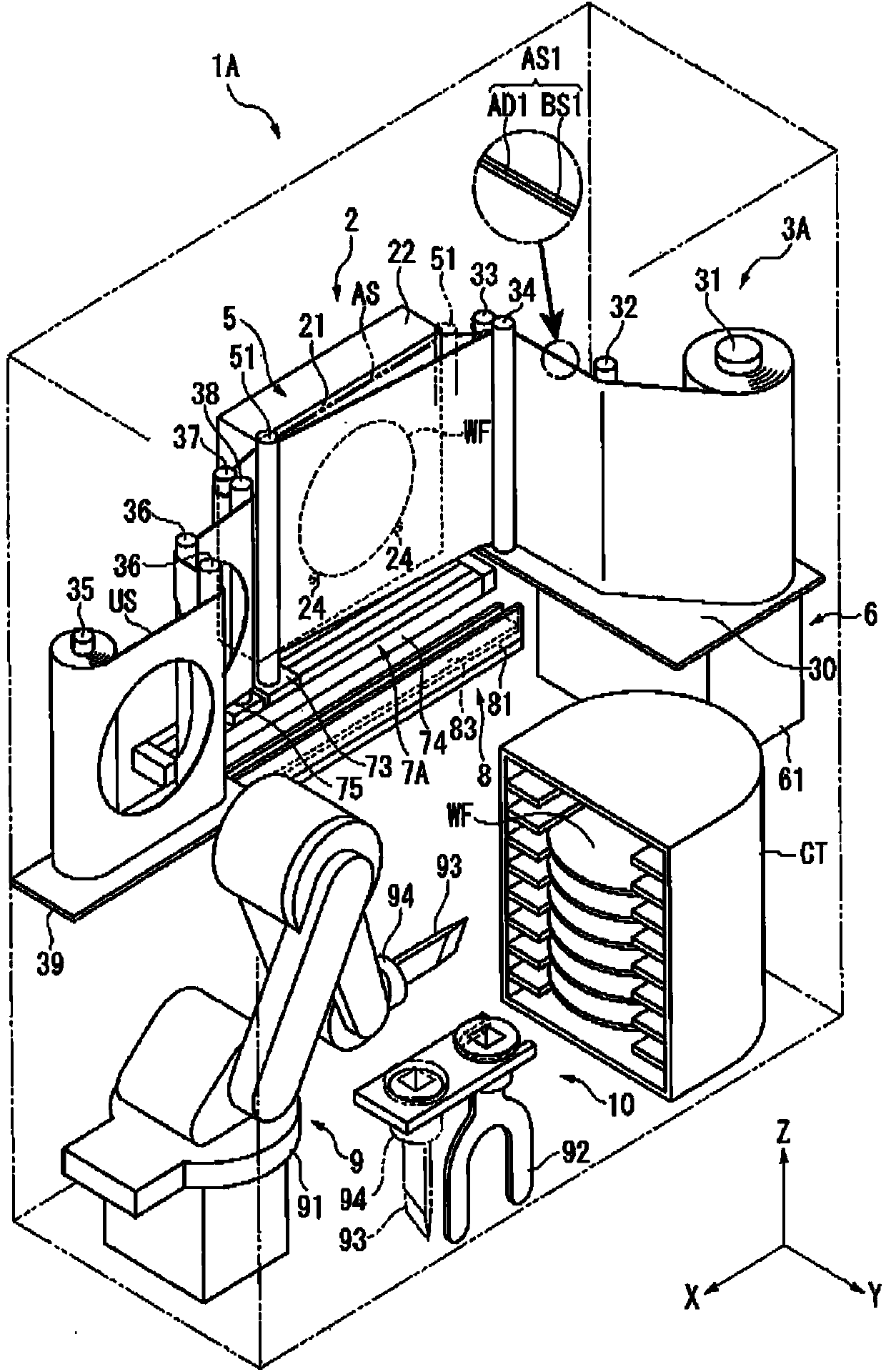

[0069] Next, based on image 3 A second embodiment of the present invention will be described.

[0070] The sheet sticking apparatus 1A of this embodiment differs from the first embodiment in that it does not include a peeling device and that it includes a cutting device 10 and has an adhesive layer AD1 on one side of the strip-shaped base sheet BS1. After sticking the tape-shaped adhesive sheet AS1 as the object to be extracted on the wafer WF, the adhesive sheet AS1 is cut. In addition, the configurations of the drawing device 3A and the moving device 7A are different from those of the first embodiment.

[0071] The take-out device 3A is equipped with: a support roller 31 that winds and supports the adhesive sheet AS1 in the form of a belt; a guide roller 32 that guides the adhesive sheet AS1; a driving roller 33 driven by a driving device not shown in the figure; The pinch roller 34 with the sheet AS1 sandwiched between it and the driving roller 33; a plurality of guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com