Generator for automobile

A technology for alternators and vehicles, applied in engine-driven traction, applications, electromechanical devices, etc., which can solve problems such as deterioration of radiator cooling performance and temperature rise of voltage regulators, and achieve the goal of suppressing temperature rise and expanding the installation area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

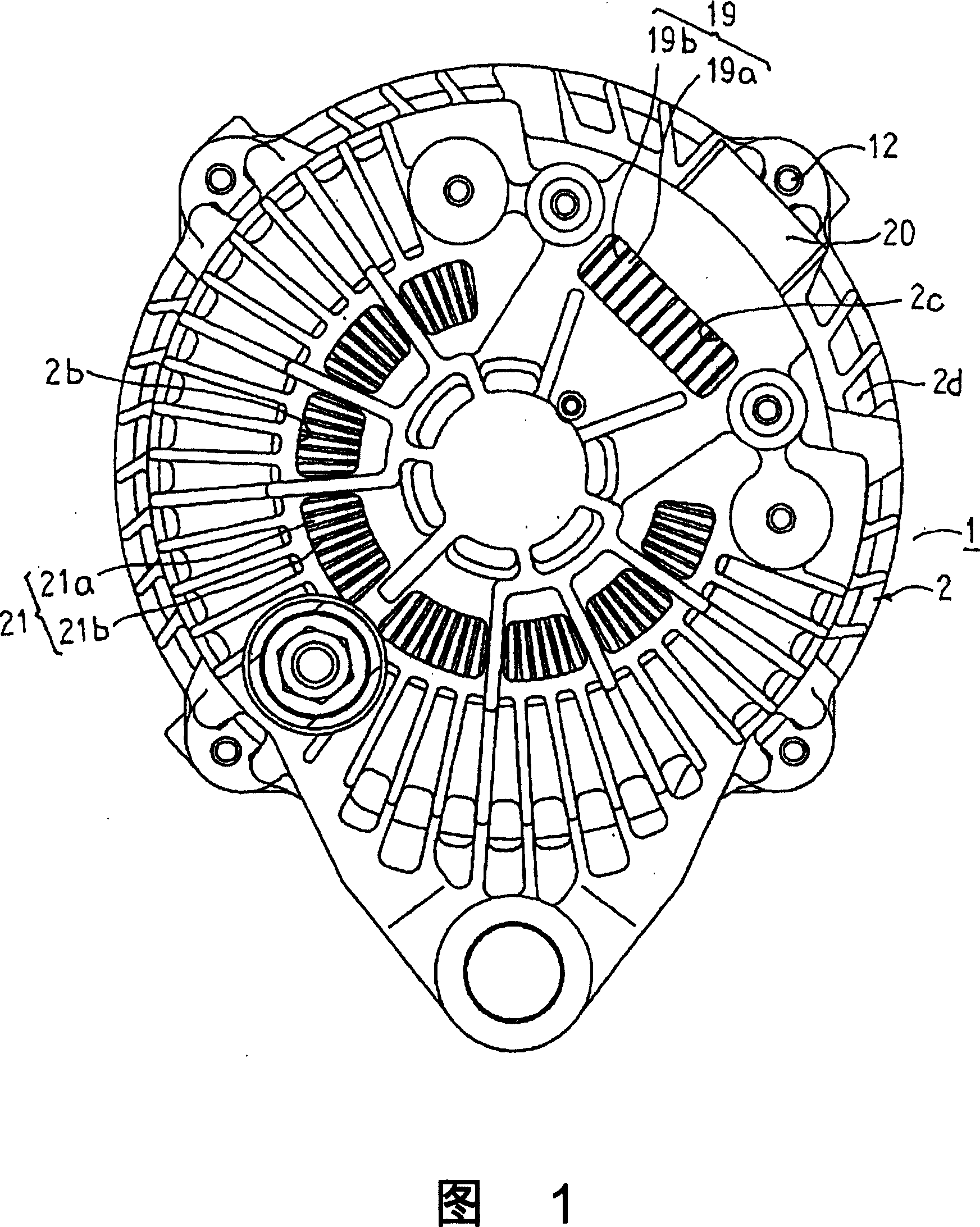

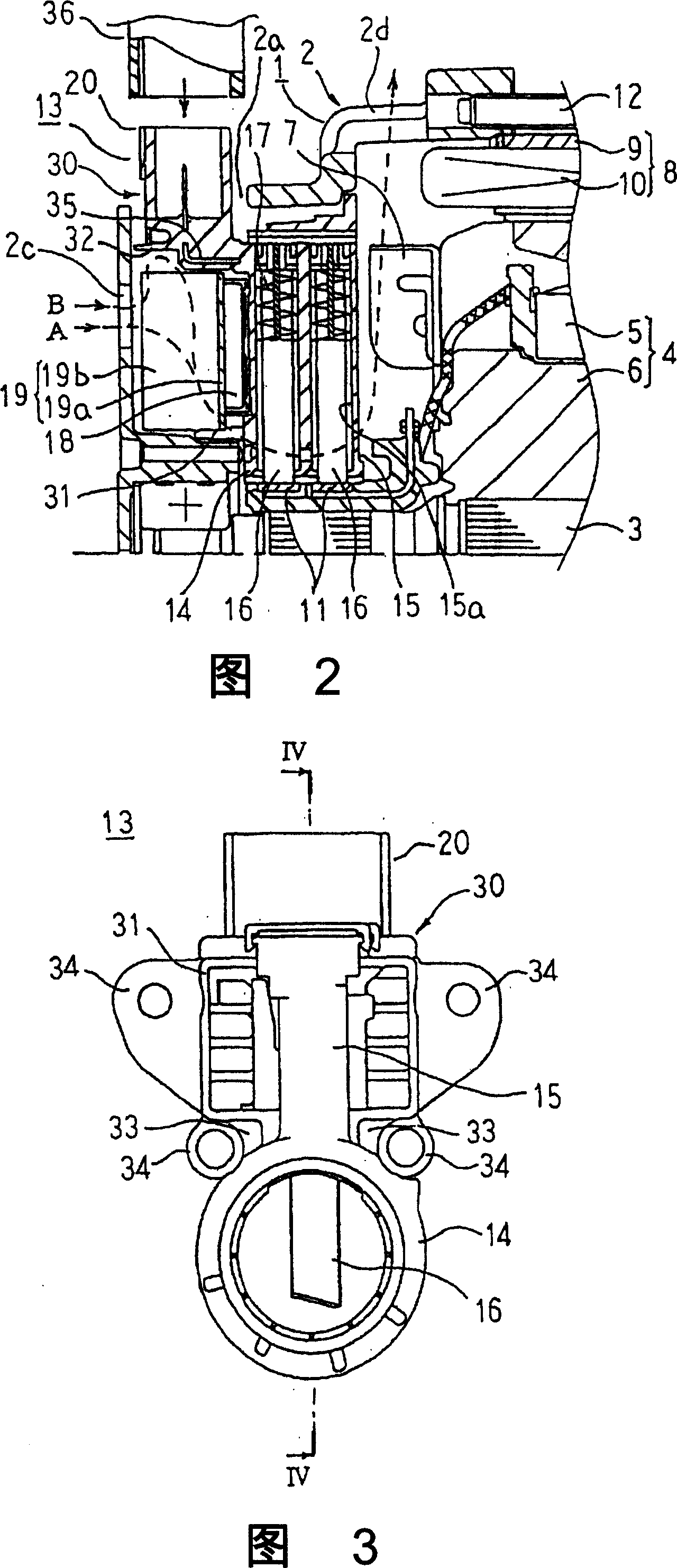

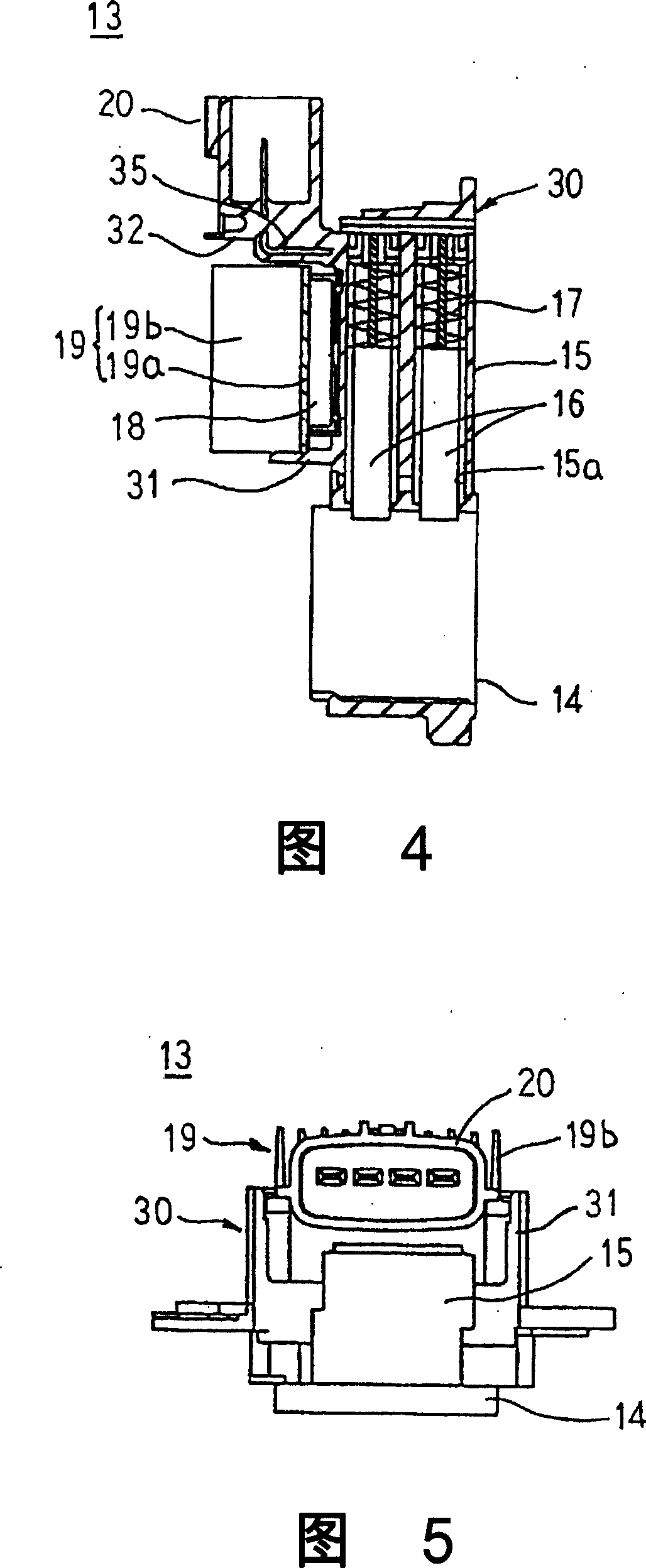

[0037] 1 is a view from the back of the vehicle alternator according to the embodiment of the present invention, FIG. 2 is a sectional view showing the main part of the vehicle alternator according to the embodiment of the present invention, The front view of the regulator assembly applicable to the vehicle alternator related to the embodiment of the present invention, Fig. 4 is a longitudinal sectional view of the IV-IV arrow in Fig. 3, Fig. 5 is a view from the side of the connector opening. Figure 6 and Figure 7 are diagrams for explaining the flow of cooling air in the vehicle alternator according to the embodiment of the present invention, respectively. A perspective view of the main parts.

[0038] In FIGS. 1 and 2 , the vehicle alternator has a housing 1 composed of a roughly bowl-shaped aluminum front cover (not shown) and a rear cover 2, supported by the housing 1 and capable of The rotating shaft 3 that rotates freely, the rotor 4 that is fixed on the rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com