Method for manufacturing oil-gas-exploration special fiber rope

A special fiber and cable technology, applied in the field of oil and gas exploration, can solve problems such as performance degradation, and achieve the effect of reducing oil production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

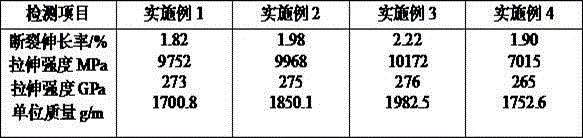

Examples

Embodiment 1

[0013] First, the carbon fiber is pretreated, subjected to acetone ultrasonication for 5 minutes, and then roughened. Then, the carbon fiber is passed through the glue tank of the hot-melt adhesive film machine equipped with the prepared resin matrix, 30 parts of epoxy resin, 10 parts of methyl tetrahydrophthalic anhydride, and 3 parts of toughening agent. Evenly transfer the resin to the release paper, so that the prepared film is continuous, uniform and flat, with an area density of 37±3g / m.

[0014] Then, 60 parts of 500k carbon fibers are flattened and soaked with an adhesive film to make a prepreg with an area density of 210±10g / m (the mass of fiber in the area density is 160g / m), and the temperature of the prepreg is 75°C , The prepreg pressure is 0.3MPa, the prepreg running speed is 1.0m / min, and the precuring is 1.5h.

[0015] The impregnated carbon fiber tow is twisted by a twisting machine at a twisting speed of 15n / m, and cured for 1h. The twisted tow is coated wi...

Embodiment 2

[0017] First, the carbon fiber is pretreated, subjected to acetone ultrasonication for 5 minutes, and then roughened. Then, the carbon fiber is passed through the glue tank of the hot-melt adhesive film machine equipped with the prepared resin matrix, 35 parts of epoxy resin, 10 parts of methyl tetrahydrophthalic anhydride, and 0.3 part of toughening agent. Evenly transfer the resin to the release paper, so that the prepared film is continuous, uniform and flat, with an area density of 37±3g / m.

[0018] Then, 55 parts of 500k carbon fibers are flattened and soaked with an adhesive film to make a prepreg with an area density of 210±10g / m (the mass of fiber in the area density is 160g / m), and the temperature of the prepreg is 75°C , The prepreg pressure is 0.3MPa, the prepreg running speed is 1.0m / min, and the precuring is 1.5h.

[0019] The carbon fiber tow of the prepreg is twisted by a twisting machine at a twisting speed of 15n / m, and cured for 1h. The twisted tow is coate...

Embodiment 3

[0021] First, the carbon fibers were pretreated, ultrasonically treated with acetone for 5 minutes, and then roughened. Then, the carbon fiber is passed through the glue tank of the hot-melt adhesive film machine equipped with the prepared resin matrix, 40 parts of epoxy resin, 10 parts of methyl tetrahydrophthalic anhydride, and 0.3 part of toughening agent. Evenly transfer the resin to the release paper, so that the prepared film is continuous, uniform and flat, with an area density of 37±3g / m.

[0022] Then, 50 parts of 500k carbon fibers are flattened and soaked with an adhesive film to make a prepreg with an area density of 210±10g / m (the fiber content in the area density is 160g / m), and the temperature of the prepreg is 75°C , The prepreg pressure is 0.3MPa, the prepreg running speed is 1.0m / min, and the precuring is 1.5h.

[0023] The impregnated carbon fiber tow is twisted by a twisting machine at a twisting speed of 15n / m, and cured for 1h. The twisted tow is coated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| linear density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com