Novel vertical mechanical reversing energy-saving pumping unit

A mechanical commutation, pumping unit technology, applied in mechanical equipment, production fluids, wellbore/well components, etc., can solve the problems of reduced buffering effect, deterioration of the use of the whole machine, grid interference, etc., and achieves an increase in the displacement coefficient and full factor, fewer stress cycles, and less actual stroke loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The present invention will be further described below in conjunction with the accompanying drawings. It should be understood that the accompanying drawings only depict some preferred implementations of the present invention, and do not limit the protection scope of the present invention, which is only limited by the claims.

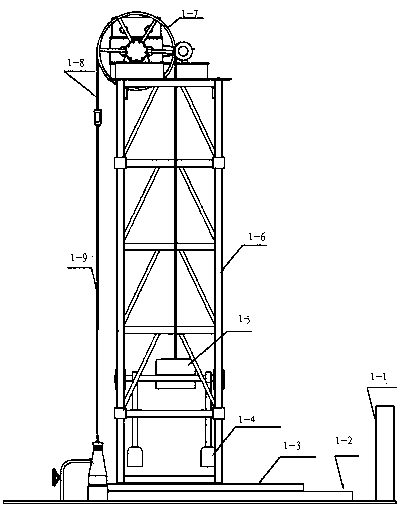

[0081] combine figure 1 The overall structure of the vertical mechanical reversing energy-saving pumping unit of the present invention can be understood. The pumping unit of the present invention adopts a vertical structure layout, mainly including frame 1-6, sky wheel 1-7, mechanical reversing reducer, crank buffer device 1-4, steel wire rope 1-8, rope suspension device, counterweight 1-5. Auxiliary hydraulic system, electrical control cabinet 1-1, workover shifting device and other parts. The upper end of the polished rod 1-9 is connected with the steel wire rope 1-8, and the lower end is connected with the oil production rod. The workover sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com