Steam injection technology method of high-temperature mixer generators

A process method and mixer technology, which is applied in the direction of earthwork drilling, mining fluid, wellbore/well components, etc., to achieve the effect of sufficient combustion process and vaporization mixing process, prolonging service life and improving cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

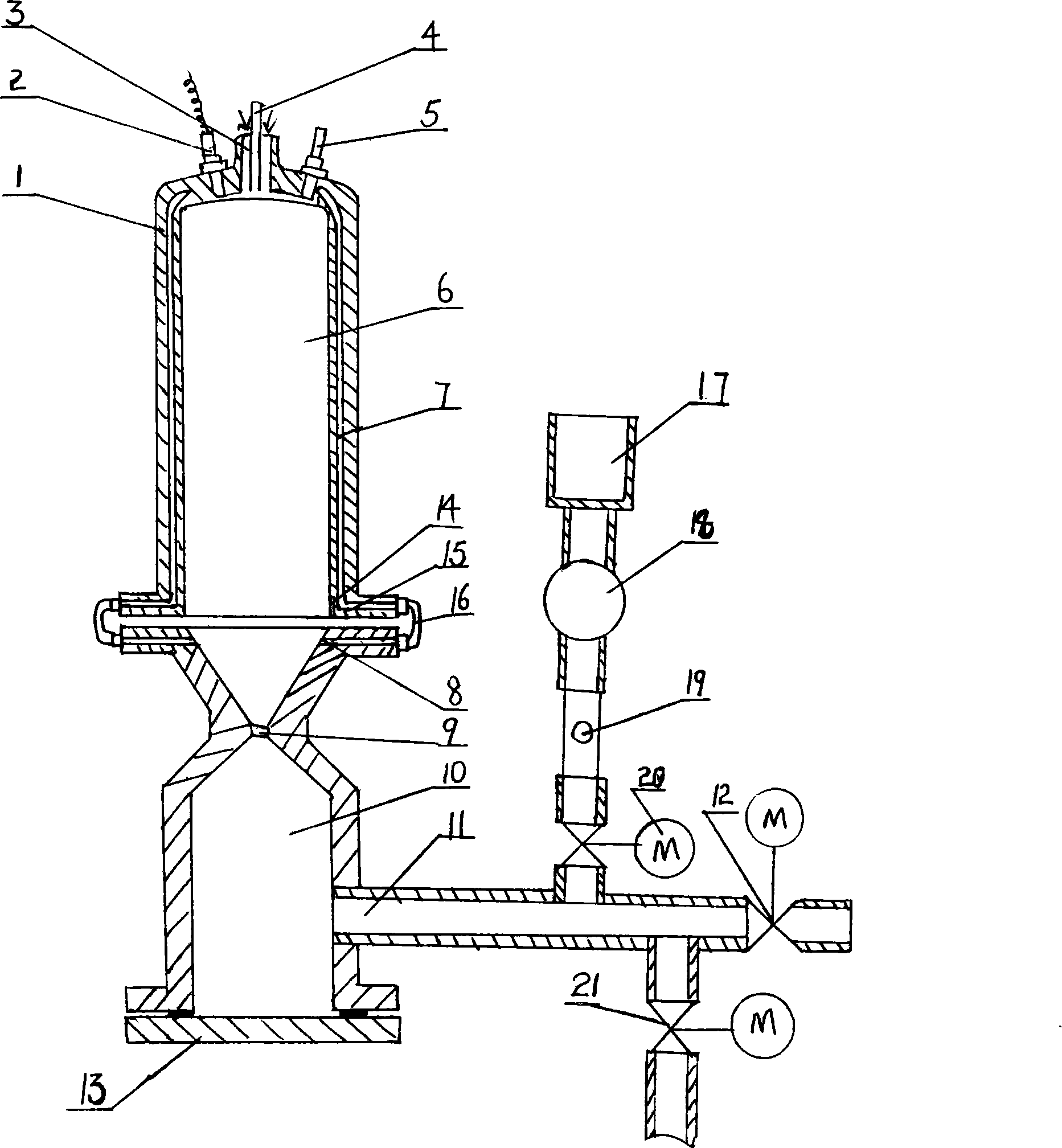

Image

Examples

Embodiment Construction

[0016] The concrete technical scheme of the present invention will be further described below in conjunction with embodiment:

[0017] As shown in the figure, this high-temperature mixer generator used in the present invention includes a body composed of a combined head, a combustion chamber 6, a buffer chamber 10 and a base 13, and an independent combustion chamber between the inner wall 14 and the outer wall 7. Closed-circuit cooling water circulation system 1, water inlet 5 and vaporized water injector 8, in which the combined head with high-pressure air nozzle 3, high-voltage electric spark plug 2 and fuel nozzle 4 is assembled with a detachable connection structure At the upper end of the combustion chamber 6, it can be replaced at any time according to the actual operating conditions, so as to adapt to the combustion conditions of various fuels, such as diesel oil, crude oil, natural gas, etc., and widen the scope of application of the fuel nozzle; wherein the lower end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com