Magnetic fluid polished rod sealer for oil production in oilfield

A polished rod sealer, magnetic fluid technology, applied in sealing/isolation, earthwork drilling, wellbore/well components, etc., can solve the problems of easy to wear and break sucker rods, waste of oil and gas resources, hidden dangers of oilfield safety, etc. , to avoid air pollution and ground pollution, reduce friction loss, and improve resource recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

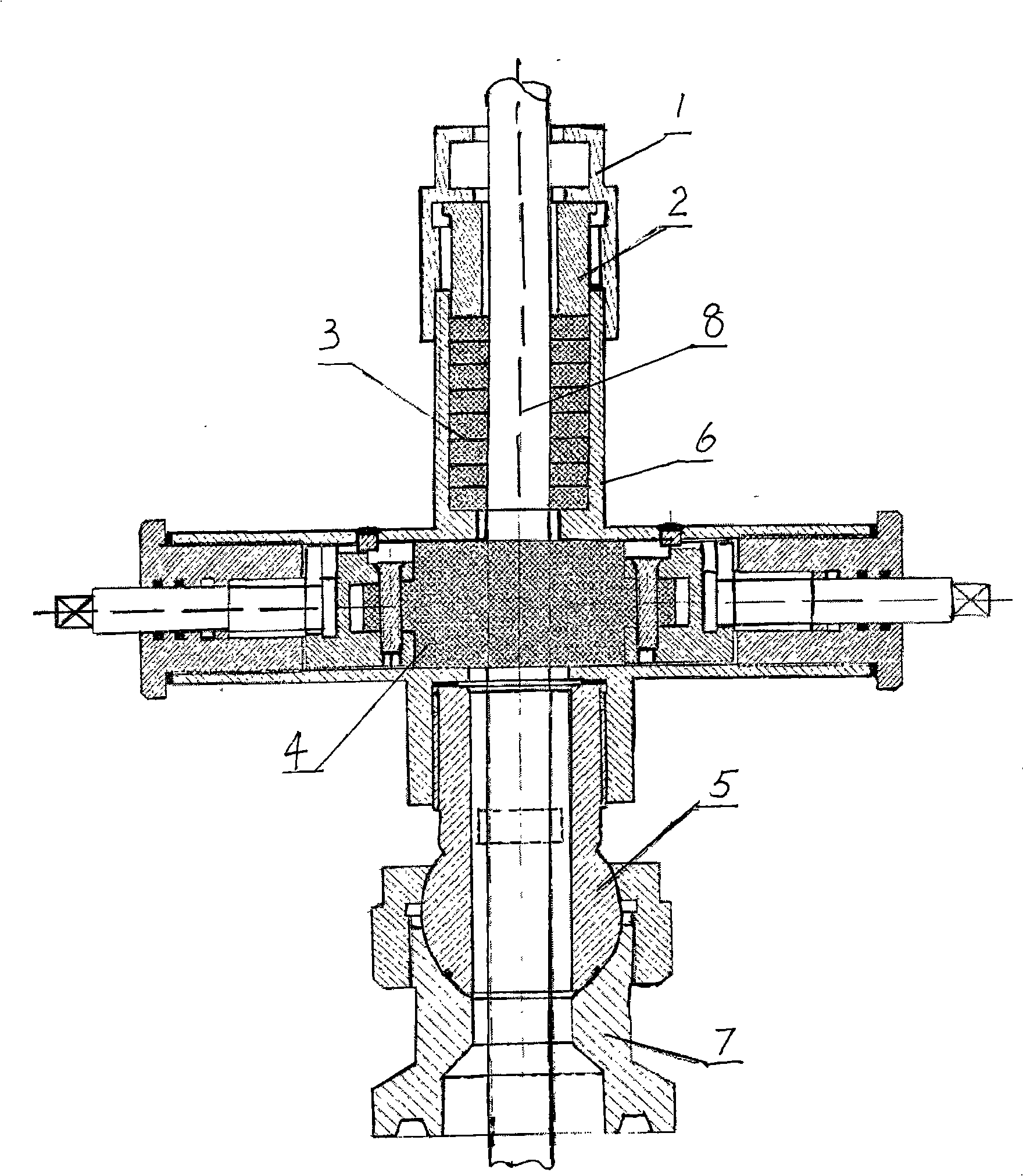

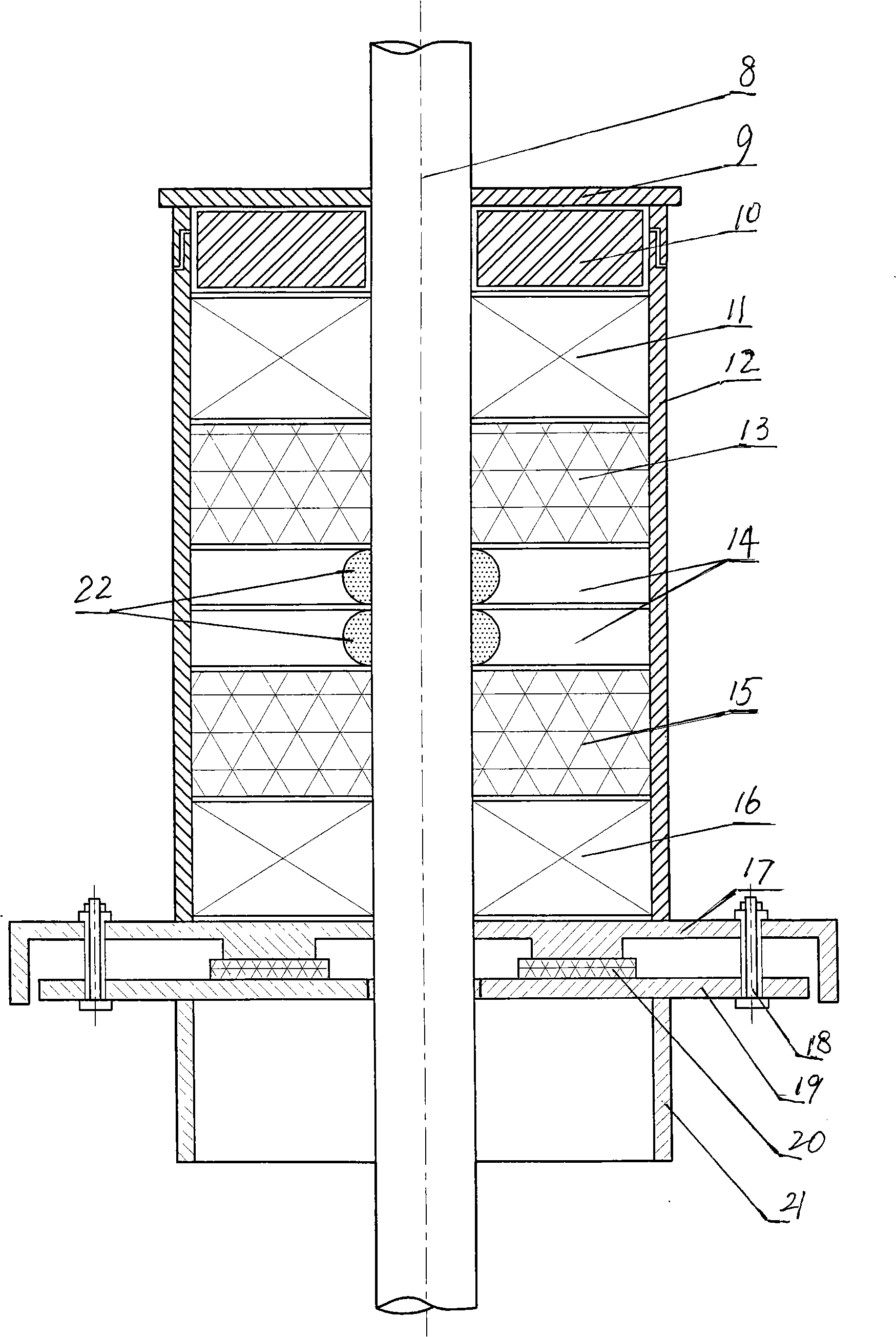

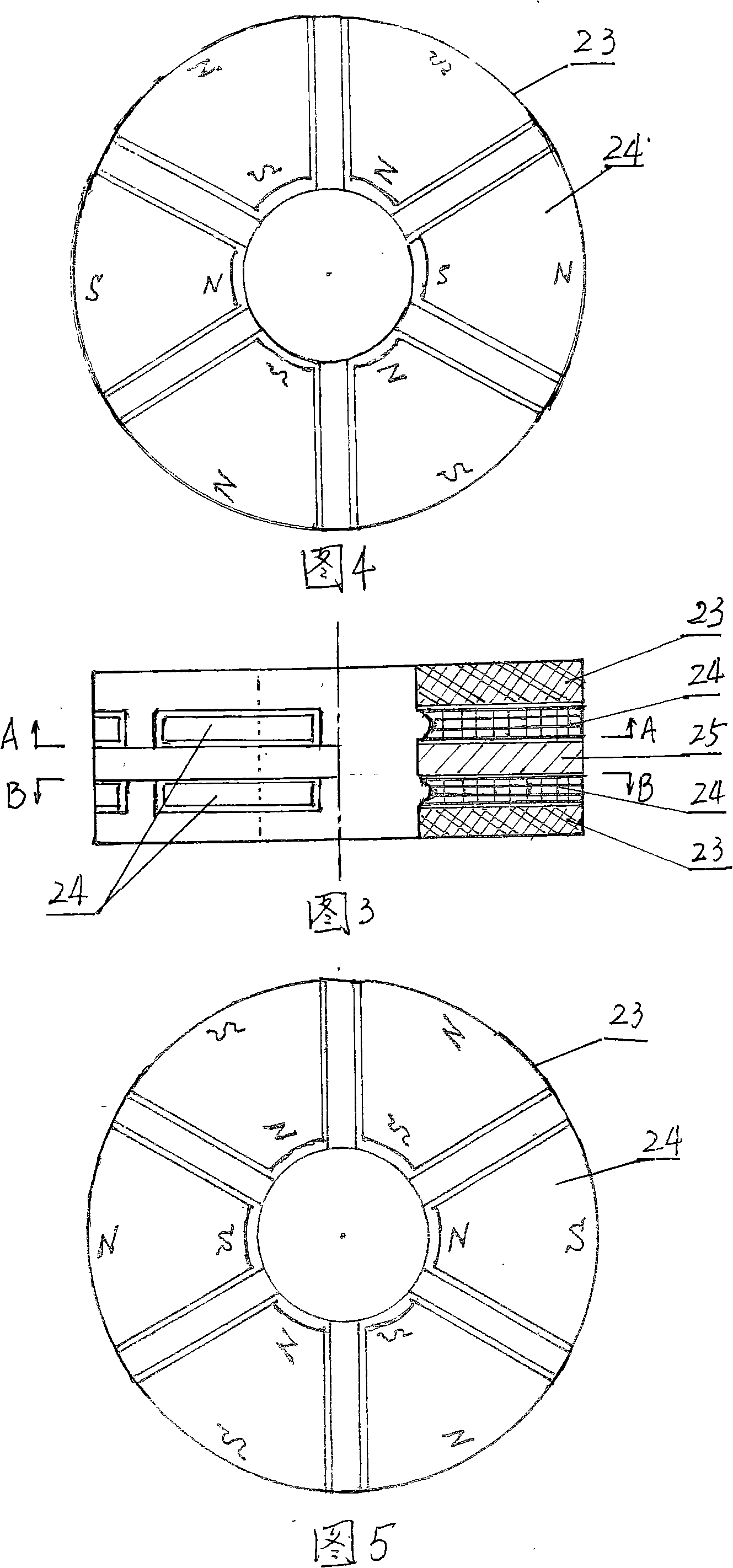

[0049] see figure 2, the present invention adopts the steel pipe to make the case 12, the upper end of the case 12 is equipped with a gram 10 and a gland 9, the bottom of the case 12 is welded with an upper flange 17, and the case 12 is set on the outside of the polished rod 8; and Two layers of magnetic sealing sleeves 14 are stacked in the casing, and its structure is shown in Fig. Silicon steel sheets 25 are installed, and six permanent magnet blocks 24 are respectively installed in the two magnetic block casings 23. The permanent magnet blocks 24 in the same layer are arranged in pairs with opposite poles, and the upper and lower permanent magnet blocks 24 have the same magnetic poles reversed. layout. (Permanent magnet block 24 can select Nd for use 2 Fe14B rare earth permanent magnet material or Sm-Fe-N series rare earth permanent magnet material or other permanent magnet materials, its main technical indicators are: saturation magnetization Mo = 1.6T; coercive force ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com