Movable barrel type rotary plunger oil well pump

A rotary column and moving cylinder type technology, applied in the field of moving cylinder rotary plunger oil well pump, can solve problems such as increased energy consumption, impact on oil production, increased friction between the plunger and the pump barrel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

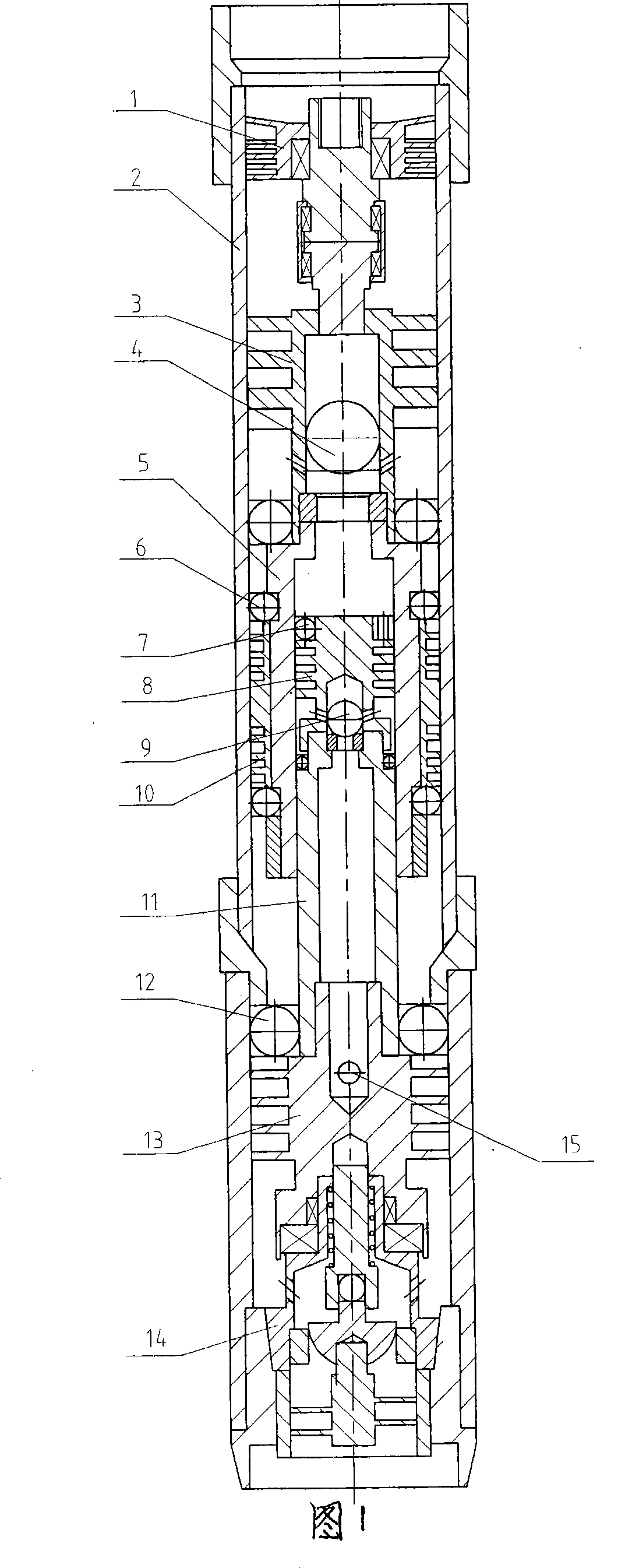

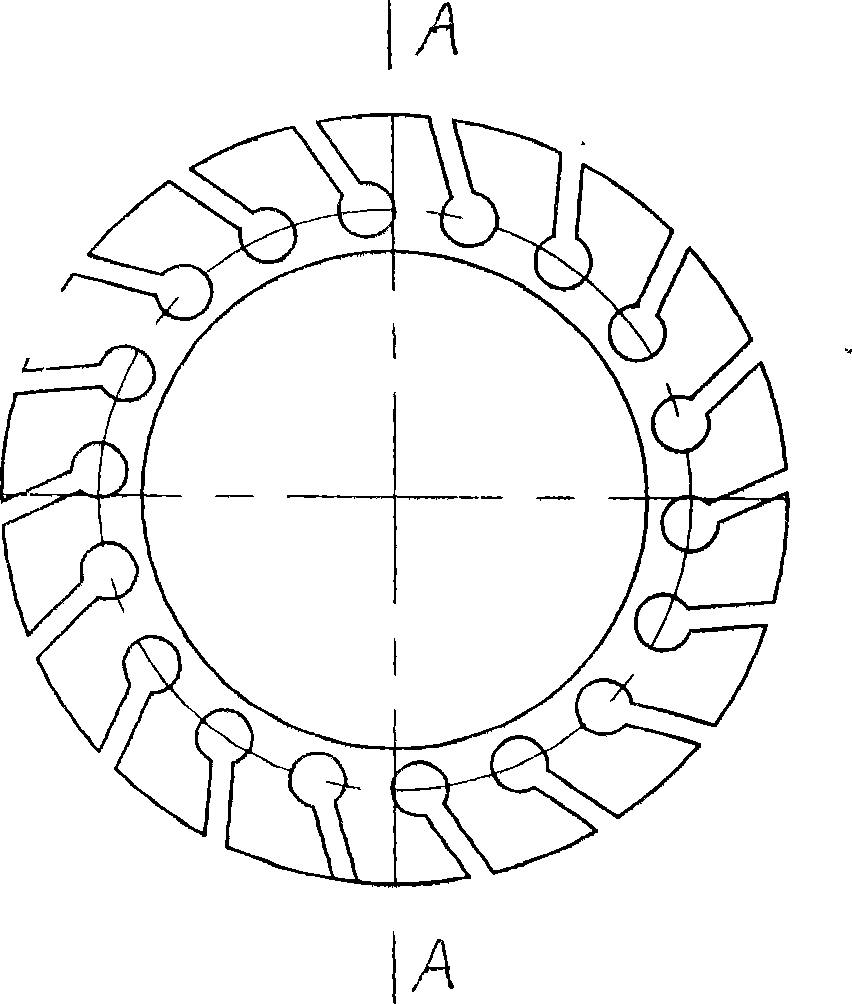

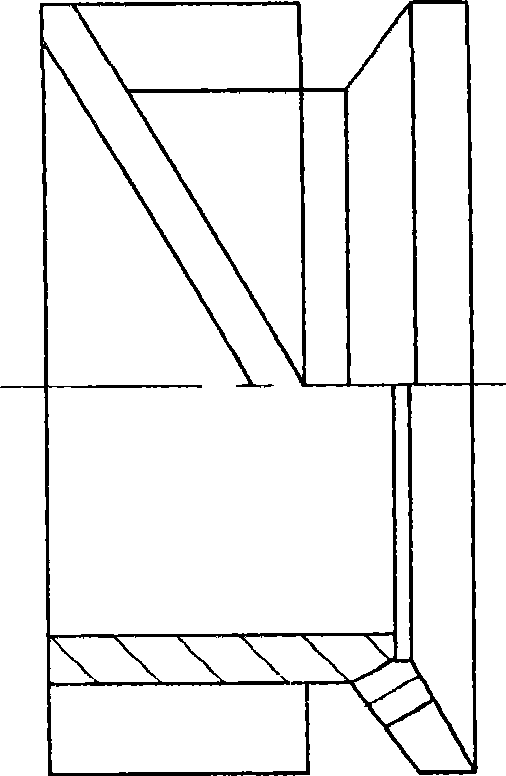

[0005] The present invention is described in detail in conjunction with the above accompanying drawings. In the pump cylinder 2, a moving cylinder 5 and a plunger body 11 are provided. Spiral pieces are evenly distributed on the top, and the lower end of the spiral flow channel formed between the spiral pieces communicates with the axial hole in the plunger body through the radial oblique hole 15 and the axial blind hole of the thruster body. The lower thruster is rotatably supported on the pump body. On the hemispherical fixed valve 14 at the lower end of the barrel, the lower end of the thruster 8 on the plunger is connected with the upper end of the plunger 11 with threads, and the upper end of the plunger is provided with an oil inlet valve and a valve ball 9, and the upper end of the thruster on the plunger is The body is evenly distributed with spiral pieces, and the spiral flow channel formed between the spiral pieces communicates with the plunger oil outlet valve throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com