Binary alkali-free complex composition for flooding, suitable for high-temperature and high-salinity reservoir, and application thereof

An alkali-free composite flooding, high-temperature and high-salt technology, which is applied to drilling compositions, production fluids, wellbore/well components, etc. Solve problems such as salt and temperature resistance, and achieve the effect of overcoming the rise of interfacial tension, good emulsification performance, and low interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

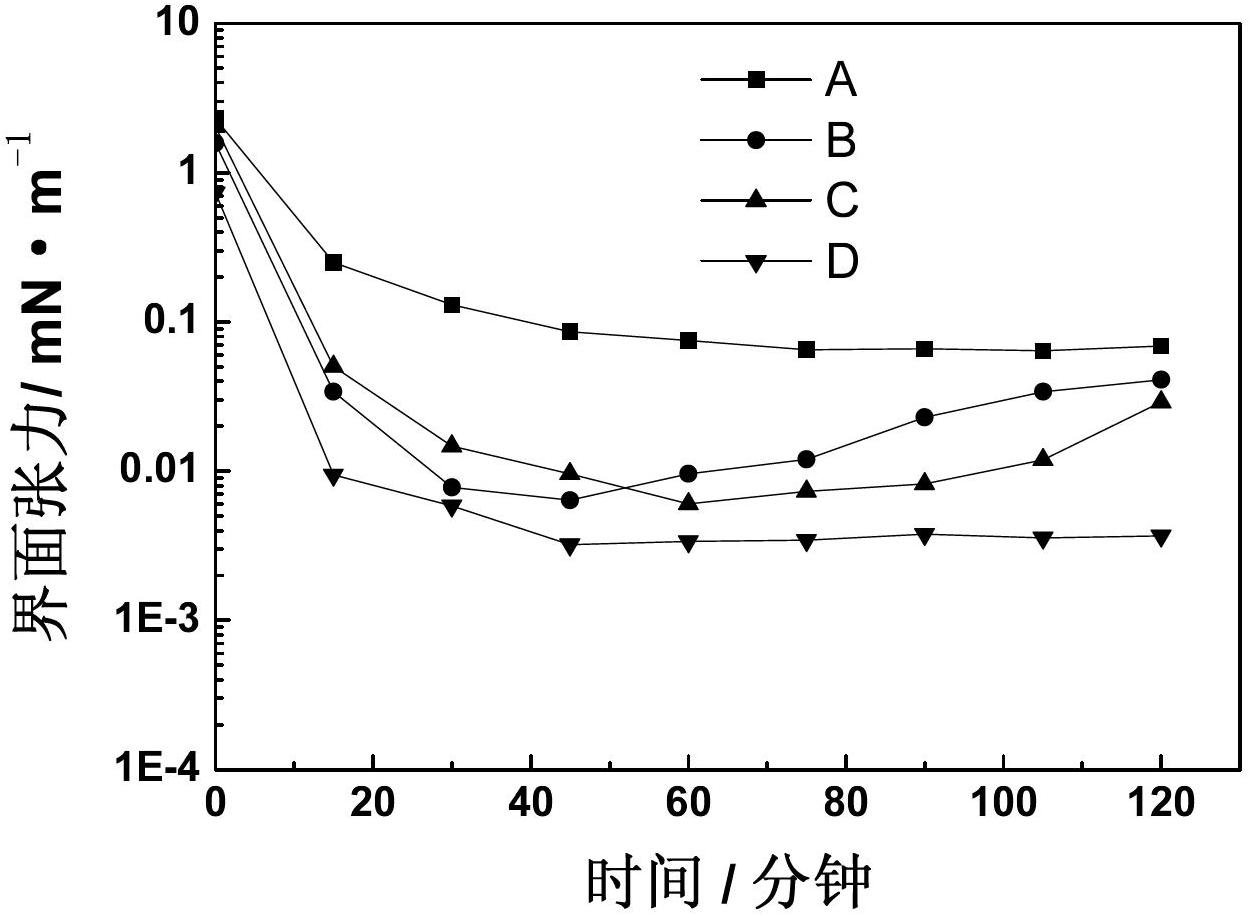

[0032] Embodiment 1 interface performance test

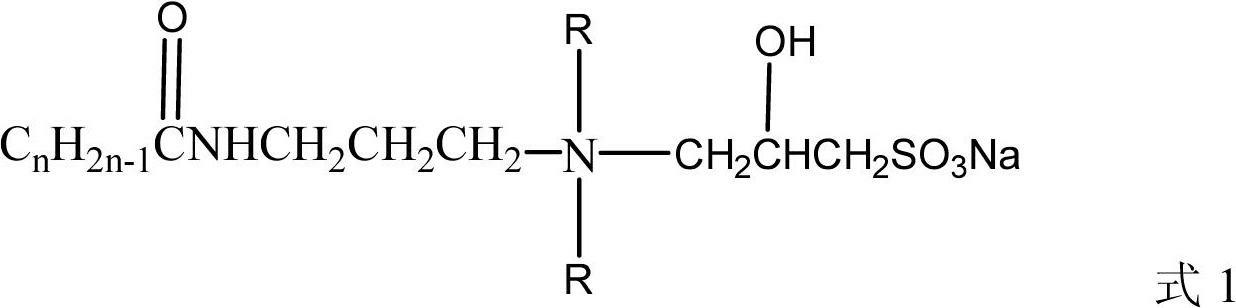

[0033] In this example, the compositions for oil displacement using carbooctadecyl dimethyl hydroxysultaine, oleic acid amido hydroxysultaine, and erucic acid amido hydroxysultaine as surfactants and the Oleic acid amido sulfobetaine and carbon octadecyl dimethyl hydroxysulfobetaine as a composite surfactant binary non-alkali composite oil flooding composition has been tested for interfacial properties, wherein the above-mentioned oleic acid The structures of amido sulfobetaine, erucic acid amido sulfobetaine and carbooctadecyl dimethyl sulfobetaine are shown below respectively (the hydroxysulfobetaine in the following examples is the same as here same as sulfobetaine):

[0034] Oleamide Hydroxysultaine:

[0035]

[0036]Erucic acid amido sulfobetaine:

[0037]

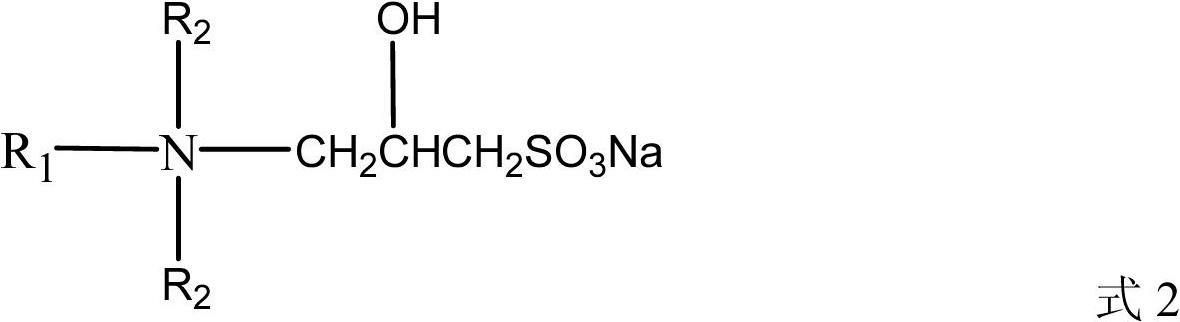

[0038] Carbooctadecyldimethylhydroxysultaine:

[0039]

[0040] experiment method:

[0041] Formation water with a salinity of 84000mg / L was used to prepa...

Embodiment 2

[0047] Embodiment 2 Composite surfactant ratio optimization

[0048] In this example, the interfacial properties of the composite surfactant composed of oleic acid amido sulfobetaine and carbadecyl dimethyl sulfobetaine were studied. The above composite surfactants are oleic acid amido sulfobetaine and carbooctadecyl dimethyl sulfobetaine in different mass ratios.

[0049] Test method: Formation water with a salinity of 84000 mg / L was used as a solvent to prepare a solution with a composite surfactant concentration of 0.2 wt%, and no polymer was added. The interfacial tension of the above solution was tested with a TX500C interfacial tension tester by the rotating drop method. The test temperature was 80° C. and the rotational speed was 5000 RPM. The test results are shown in Table 1.

[0050] Table 1 Interfacial Tension Test Results

[0051] Oleic acid amido sulfobetaine: carbooctadecyldimethyl sulfobetaine

[0052] As can be seen from Table 1, within the formula ...

Embodiment 3

[0053] Embodiment 3 Viscosity test

[0054] In this example, the viscosity of the binary non-alkali composite oil flooding composition using a composite surfactant is tested.

[0055] Test method: Formation water with a salinity of 84000mg / L is used to prepare a polymer one-component system solution and a polymer / composite surfactant binary system solution (that is, a composition for binary alkali-free composite oil flooding), wherein the polymer and the concentration of composite surfactant are respectively 2000mg / L, and composite surfactant is oleic acid amido sulfobetaine and carbon octadecyl dimethyl sulfobetaine, and the mass ratio of the two is 7: 3. Three polymers were used to prepare solutions respectively, and their physical and chemical indexes are shown in Table 2. Viscosity test was carried out with American Brookfield LVDVII rotational viscometer, 0# rotor, rotating speed was 6RPM, and test temperature was 95°C. The experimental results are shown in Table 3, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com