Method for testing and dislodging oil well intelligent delamination

A technology of layered testing and intelligent switch, applied in earth-moving drilling, wellbore/well components, sealing/packing, etc., can solve the problems of complex operation, high cost, and many processes, and achieve simple operation and high success rate , the effect of reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

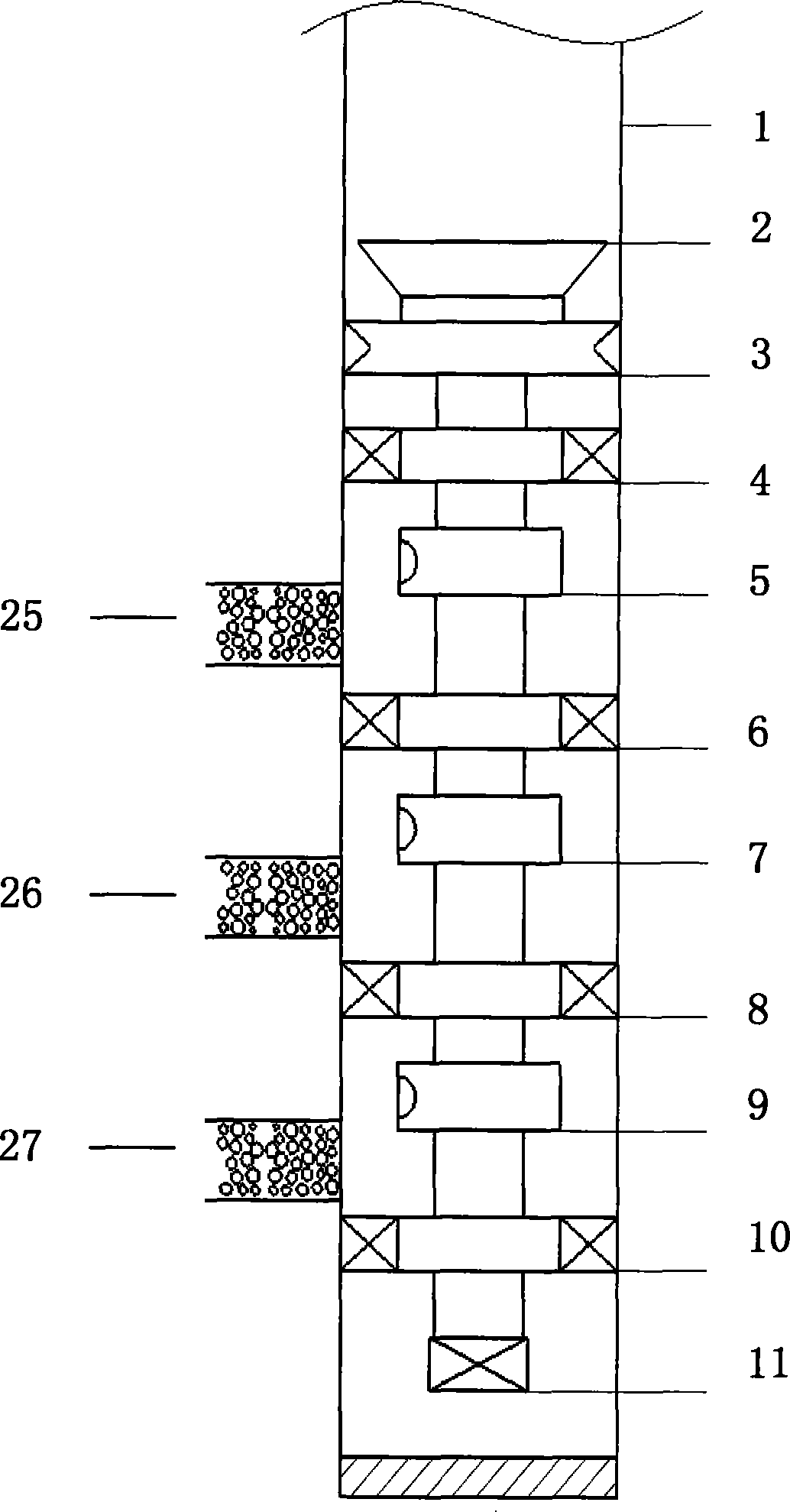

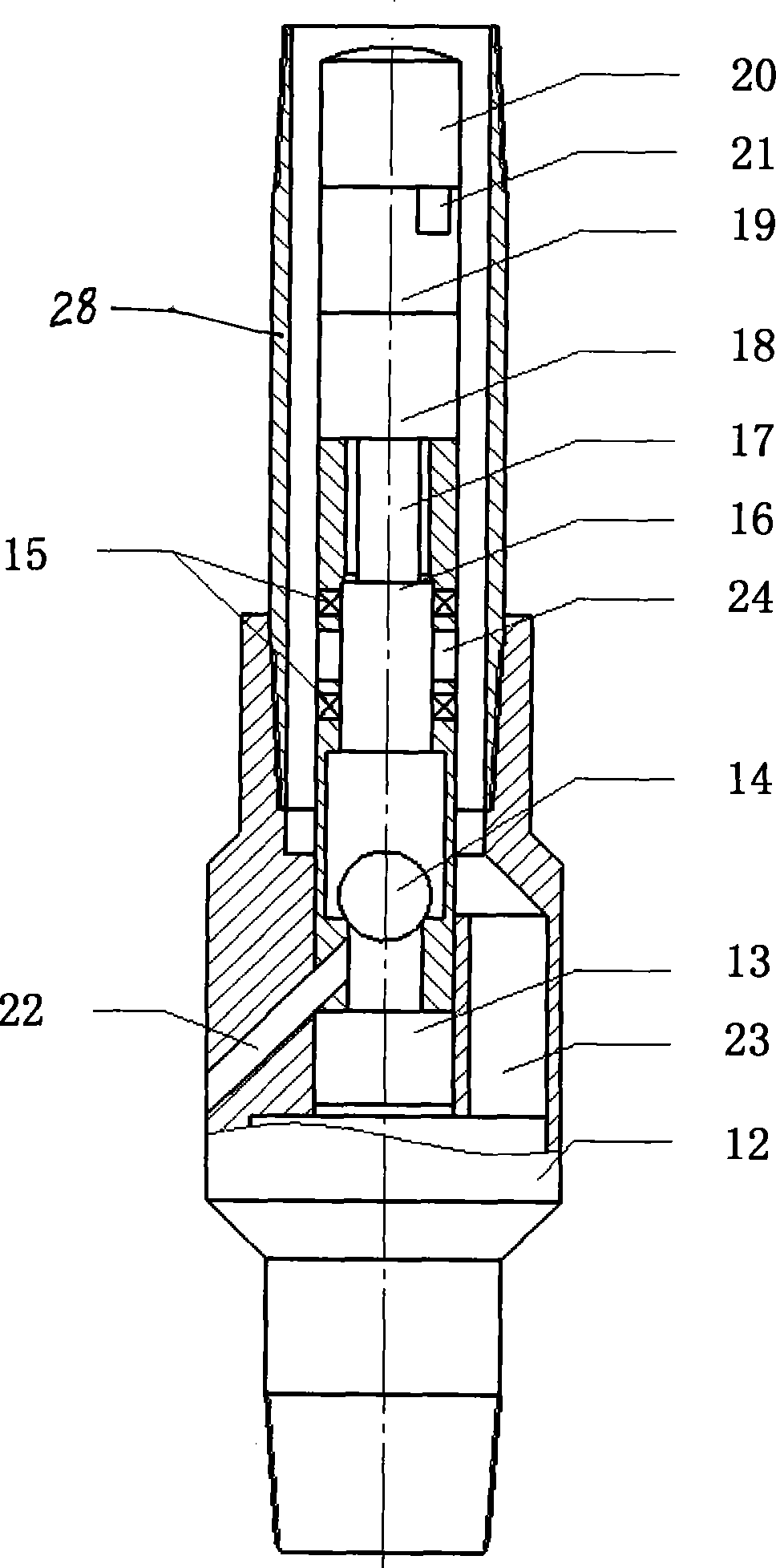

[0014] see figure 1 , figure 2 , the concrete embodiment that design is production layer 1 (25), production layer 2 (26), production layer 3 (27) three layers of oil layer exploitation. Discarding joint (2), safety joint (3), water blocking packer 1 (4), smart switch 1 (5), water blocking packer 2 (6), smart switch 2 (7), plugging The water packer 3 (8), the intelligent switcher 3 (9), and the water plugging packer 4 (10) are connected from top to bottom through short joints of tubing. Combined with the needs of the production process, the end of the water plugging packer 4 (10) is equipped with a plug (11), and according to the number of production and production layers of the oil well, the multi-level connection of the water plugging packer and the intelligent switch can be realized. Thereby, the multi-layer test of the production production layer can be realized; the intelligent intelligent switch is designed as a tool nipple, which is connected with the oil pipe up and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com