Steam assisted gravity drainage technology of double-branch horizontal well

A technology for assisting gravity and horizontal wells, which is applied in wellbore/well components, production fluids, earthwork drilling and production, etc. It can solve the problems of high drilling and oil production costs, reduce drilling and oil production costs, and increase oil recovery and oil production speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

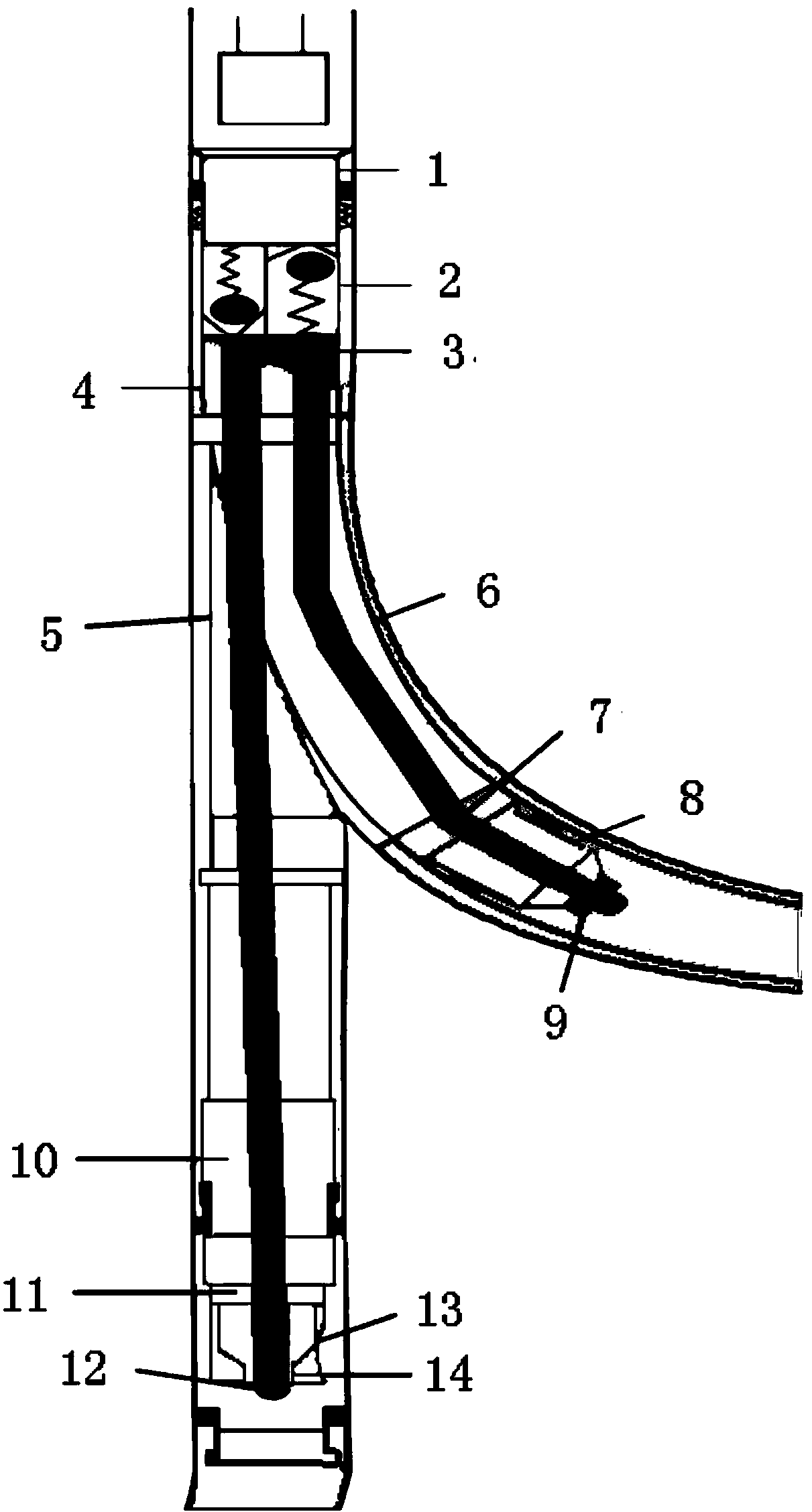

[0009] Such as figure 1 As shown, a steam-assisted gravity drainage process for a double-branched horizontal well, the following tools are required in the process of realizing this process: main borehole packer 1, injection-production valve 2, directional joint 3, directional upper bell mouth 4, Hollow deflector 5, hanger 6, Z2 inserted tubing 7, Z2 packer 8, sealing joint II 9, base 10, casing 11, sealing joint I 12, Z1 packer 13, Z1 inserted tubing 14. The process steps are as follows: in the completion process of the bibranch horizontal well, first install the directional upper bell mouth 4, and keep the slope orientation of the directional upper bell mouth 4 consistent with the hollow deflector 5; secondly, Z1 branch borehole and Z2 The branch wellbore is run into the packer and the sealing joint respectively to seal off the annulus of the Z1 branch wellbore and the Z2 branch wellbore to maintain pressure tightness; again, the main wellbore packer 1, the injection-producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com