Synthesis method of organosilicon drilling fluid water loss reducing agent

A fluid loss reducing agent and synthetic method technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of high cost of solvent separation and recovery, reduction of polymer molecular weight, low production capacity of equipment, etc., and achieve high polymerization rate Fast, high molecular weight, strong temperature and salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

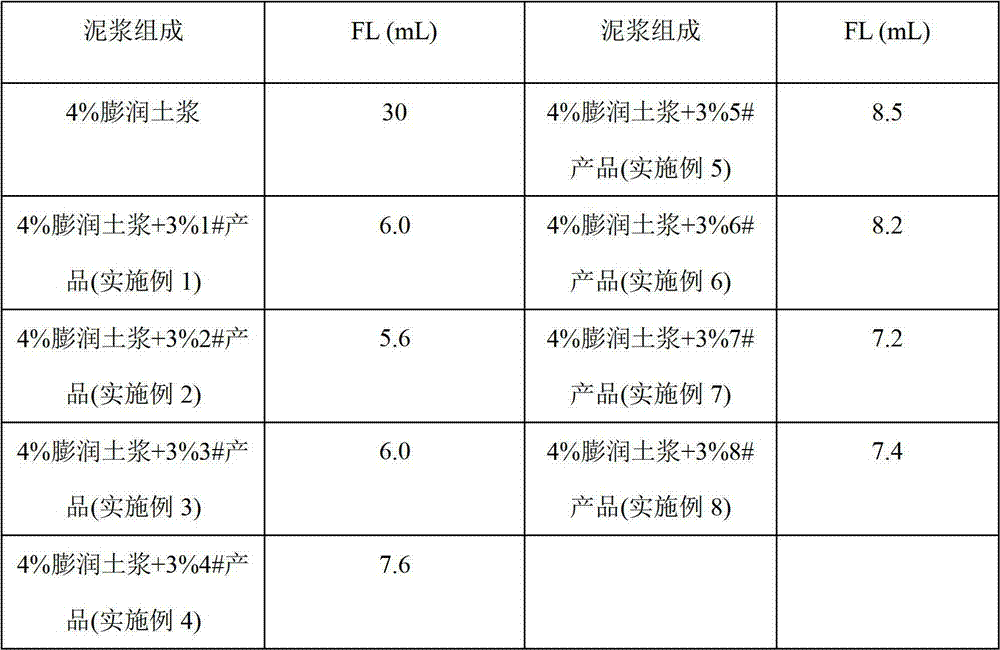

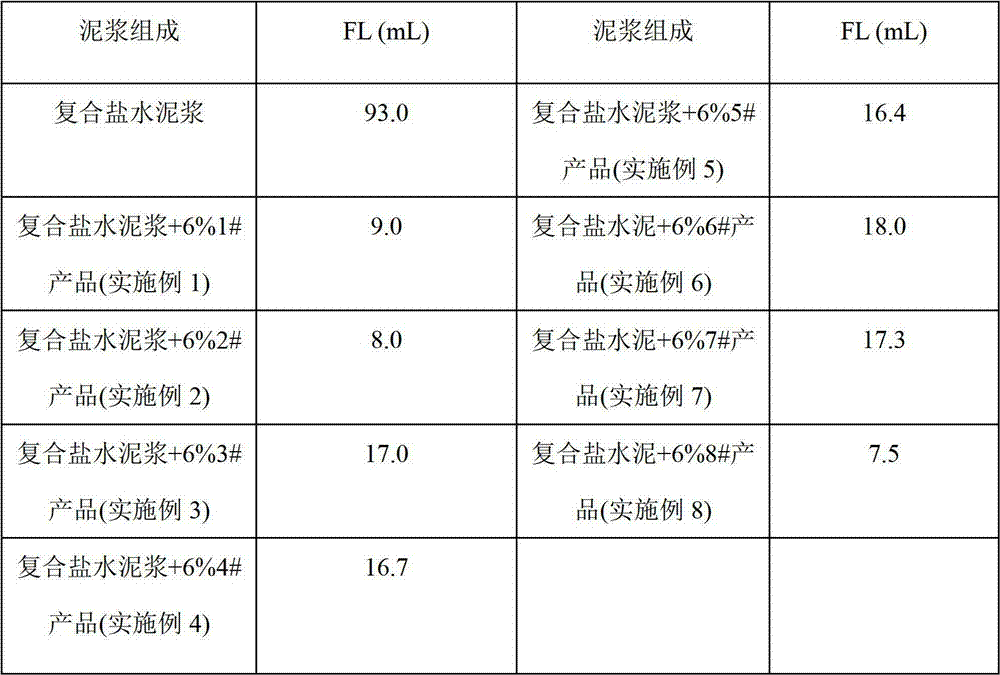

Examples

Embodiment 1

[0024] (1) Add 0.711g of acrylamide, 1.0362g of sodium 2-acrylamido-2-methylpropanesulfonate, and 0.148g of vinyltrimethoxysilane to 2.12g of N,N-dimethylformamide as a solvent , and then add 0.058g of initiator (2,4,6-trimethylbenzoyl) diphenylphosphorus oxide, avoid light and sonicate for a period of time until the mixture is completely dissolved.

[0025] (2) Take an appropriate amount of the solution and light-cure it under a UV lamp for 20 minutes to obtain a gel-like substance, soak it in anhydrous ethanol for several hours, take it out, vacuum-dry it, and grind it to obtain a white powdery copolymer product.

Embodiment 2

[0027] (1) Add 0.711g of acrylamide, 1.0362g of sodium 2-acrylamido-2-methylpropanesulfonate, and 0.739g of vinyltrimethoxysilane to 2.858g of N,N-dimethylformamide as a solvent , and then add 0.058g of initiator (2,4,6-trimethylbenzoyl) diphenylphosphorus oxide, avoid light and sonicate for a period of time until the mixture is completely dissolved.

[0028] (2) Take an appropriate amount of the solution and light-cure it under a UV lamp for 20 minutes to obtain a gel-like substance, soak it in anhydrous ethanol for several hours, take it out, vacuum-dry it, and grind it to obtain a white powdery copolymer product.

Embodiment 3

[0030] (1) Add 0.711g of acrylamide, 1.6499g of sodium 2-acrylamido-2-methylpropanesulfonate, 0.7413g of vinyltrimethoxysilane to 3.3512g of acetone, and then add 0.1548g of initiator 1 -Hydroxycyclohexyl phenyl ketone, protected from light and sonicated for a period of time until the mixture is completely dissolved.

[0031] (2) Take an appropriate amount of the solution and cure it under ultraviolet light for 25 minutes to obtain a gel-like substance, soak it in absolute ethanol for several hours, take it out and vacuum-dry it, and grind it to obtain a white powdery copolymer product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com