Preparation method of polyether ester multi-block alternating copolymer

A technology of alternating copolymers and polyether esters, which is applied in the field of preparation of new high-performance polymers, can solve problems such as difficult to obtain polyether ester copolymers, reduce high-temperature polymerization time, and complex product structures, and achieve high polymer molecular weight, The effect of fast polymerization reaction rate and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

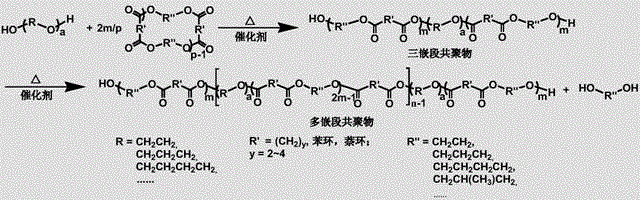

[0029] see figure 1 Shown, the synthetic preparation method of a kind of novel polyether ester multi-block alternating copolymer comprises the following steps:

[0030] Step 1) Adding the corresponding cyclic oligoester and polyether diol in the reaction device, mechanically stirring, and vacuumizing;

[0031] Step 2) heating to 120-180°C, adding the catalyst after the reactants are evenly mixed, and vacuuming;

[0032] Step 3) Elevate the temperature to 220-280°C and continue the reaction to obtain the desired target product.

Embodiment 1

[0034] Under the vacuum condition, prepare polyethylene adipate (PEA) and polytetrahydrofuran (PTMO) mass ratio as the alternating multi-block copolymer of 3:1 with ring-opening-condensation polymerization method:

[0035] Add polyethylene adipate cyclic oligomers (COEAs, 15g) and polytetrahydrofuran (M n,PTMO =2900g / mol, 45g), the device was placed in a 120°C salt bath, vacuumed, and mechanically stirred. After stirring evenly, add 60 μL (0.1wt%) tetrabutyl titanate catalyst, vacuumize, and the vacuum degree is 1×10 -3 MPa. Place the reaction device in a 220°C salt bath, start the reaction, and take samples every 30 minutes to obtain multi-block polymers with different block numbers (PEA-b-PTMO-b-PEA) n . The structural formula is as follows:

[0036]

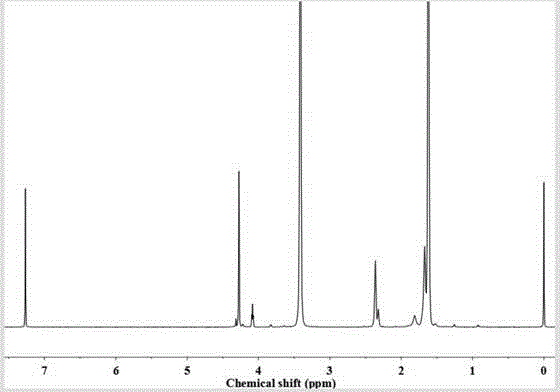

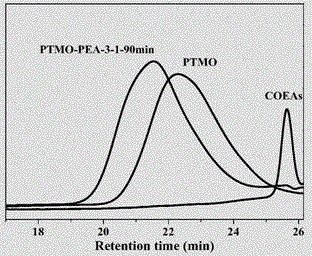

[0037] The H NMR spectrum is shown in figure 2 , proving that the target product has been successfully synthesized; in addition, the size exclusion chromatogram is shown in image 3 , which also demonstrated the succ...

Embodiment 2

[0039] Alternating multi-block copolymers with a mass ratio of polybutylene terephthalate (PBT) and polytetrahydrofuran of 3:1 were prepared by ring-opening-condensation polymerization under vacuum conditions:

[0040] In a 50mL three-necked flask, polybutylene terephthalate cyclic oligomers (COBTs, 15g) and polytetrahydrofuran (M n,PTMO =2900g / mol, 45g), the device was placed in a 180°C salt bath, vacuumed, and mechanically stirred. After stirring evenly, add 60 μL (0.1wt%) tetrabutyl titanate catalyst, vacuumize, and the vacuum degree is 1×10 -3MPa. Place the reaction device in a 240°C salt bath, start the reaction, and take samples every 30 minutes to obtain multi-block polymers with different block numbers (PBT-b-PTMO-b-PBT) n . The structural formula is as follows:

[0041]

[0042] The H NMR spectrum is shown in Figure 4 , proving that the target product has been successfully synthesized; in addition, the size exclusion chromatogram is shown in Figure 5 , whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com