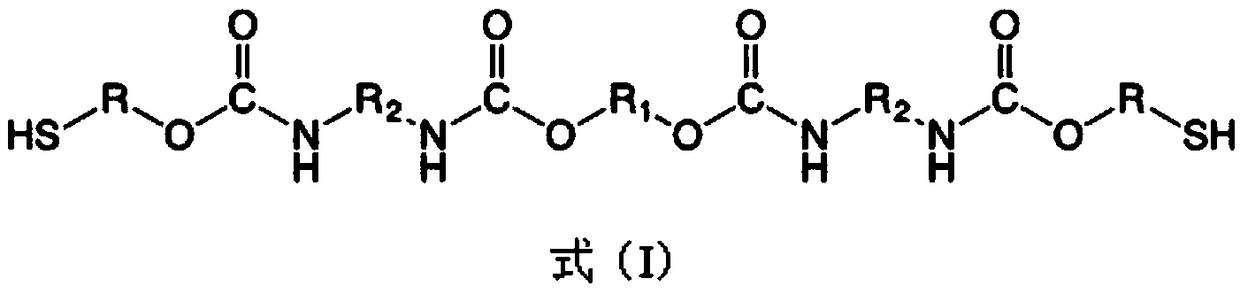

Polyurethane dithiol prepolymer, photosensitive resin composition as well as preparation method and application of prepolymer

A technology of binary mercaptan and photosensitive resin, applied in the field of polymer materials, can solve the problems of not solving the smell of mercaptan monomer, hindering the application of mercaptan-olefin photosensitive resin, and the smell of small molecule mercaptan monomer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] This embodiment provides a polyurethane dihydric thiol prepolymer (odorless polyurethane thiol monomer T1) and a photosensitive resin (photosensitive resin system S1) prepared therefrom.

[0074] The composition (mass fraction) of the photosensitive resin system S1 is as follows: polyamic acid dibasic thiol monomer T160%, tetrakis (ethylene glycol) diacrylate 38%, hydroquinone 1%, 2-hydroxy-2-methyl Base - p-hydroxyethyl ether base phenylacetone 1%.

[0075] Odorless polyurethane thiol monomer T1 and photosensitive resin system S1 can be prepared by the following method:

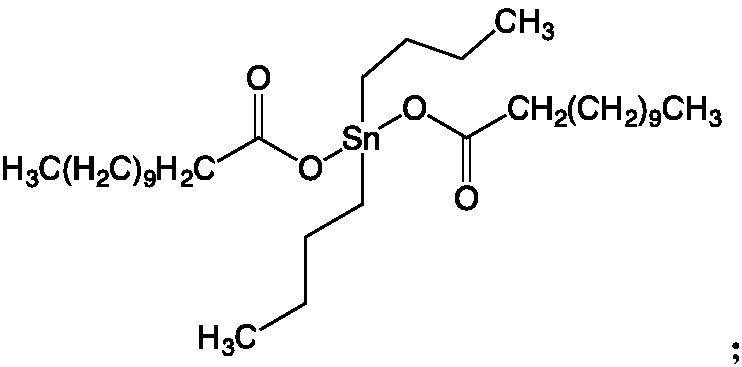

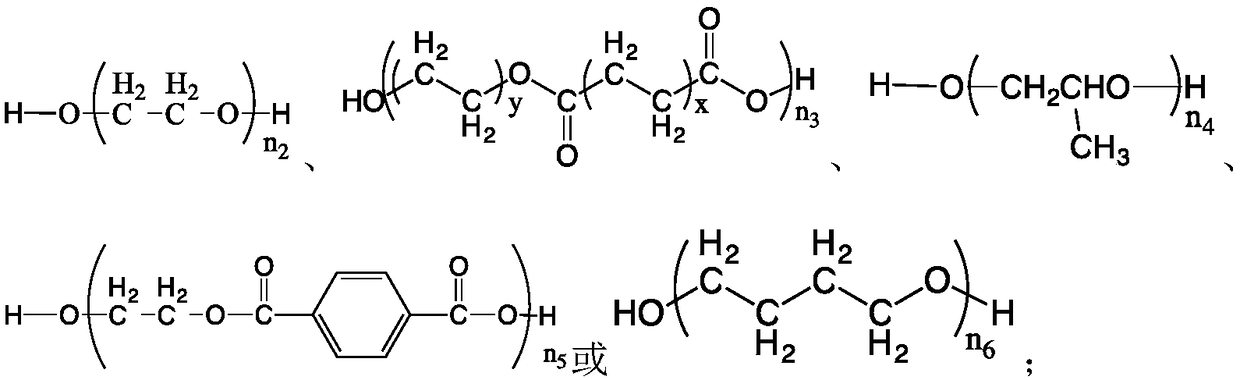

[0076] (1) Synthesis of odorless polyurethane thiol monomer T1: in a three-necked round-bottomed flask of 1000mL, under nitrogen protection, first 6-bromohexanol of 181g, isophorone diisocyanate (IPDI) of 147g and Dissolve 0.97g of dibutyltin dilaurate in 200mL of acetone, react at 50°C for 5 hours, then add 21g of polyethylene glycol (molecular weight 200), heat up to 75°C and continue to react for ...

Embodiment 2

[0079] This embodiment provides a polyurethane dihydric thiol prepolymer (odorless polyurethane thiol monomer T2) and a photosensitive resin (photosensitive resin system S2) prepared therefrom.

[0080] The composition (mass fraction) of the photosensitive resin system S2 is as follows: polyamic acid dibasic thiol monomer T250%, tetrakis (ethylene glycol) diacrylate 30%, tripropoxylated glycerol triacrylate 10%, Hydroquinone 5%, 2-hydroxy-2-methyl-p-hydroxyethyl ether phenylacetone 5%.

[0081] Odorless polyurethane thiol monomer T2 and photosensitive resin system S2 can be prepared by the following method:

[0082] (1) Synthesis of odorless polyurethane thiol monomer T2: In a 1000mL three-necked round-bottomed flask, under nitrogen protection, 150g of 2-bromoethanol, 300g of diphenylmethane diisocyanate (MDI) and 0.97 2 g of dibutyltin dilaurate, dissolved in 200 mL of acetone, reacted at 50 ° C for 5 hours, then added 290 g of polyethylene glycol (molecular weight 2000), ra...

Embodiment 3

[0085] This embodiment provides a polyurethane dihydric thiol prepolymer (odorless polyurethane thiol monomer T3) and a photosensitive resin (photosensitive resin system S3) prepared therefrom.

[0086] Odorless polyurethane thiol monomer T3 and photosensitive resin system S3 can be prepared by the following method:

[0087] The composition (mass fraction) of the photosensitive resin system S3 is as follows: polyamic acid dibasic thiol monomer T360%, tetra(ethylene glycol) diacrylate 30%, tripropoxylated glycerol triacrylate 6%, Hydroquinone 2%, 2-hydroxy-2-methyl-p-hydroxyethyl ether phenylacetone 2%.

[0088] (1) Synthesis of odorless polyurethane thiol monomer T3: in a three-necked round-bottomed flask of 1000mL, under nitrogen protection, 120g of 6-bromohexanol, 147g of dicyclohexylmethane diisocyanate (HMDI) and 0.2 g of dibutyltin dilaurate was dissolved in 200 mL of acetone, and reacted at 50° C. for 7 hours, then 620 g of polyethylene glycol oxalate (molecular weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com