High-filling highly-pressure-resistant U-PVC water supply pipe fitting

A technology for water supply pipe fittings and high-speed mixers, which is applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., which can solve the problems of pressure resistance, physical and mechanical performance degradation, silver cracks, etc., and improve interface compatibility , good stability, high pressure and high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

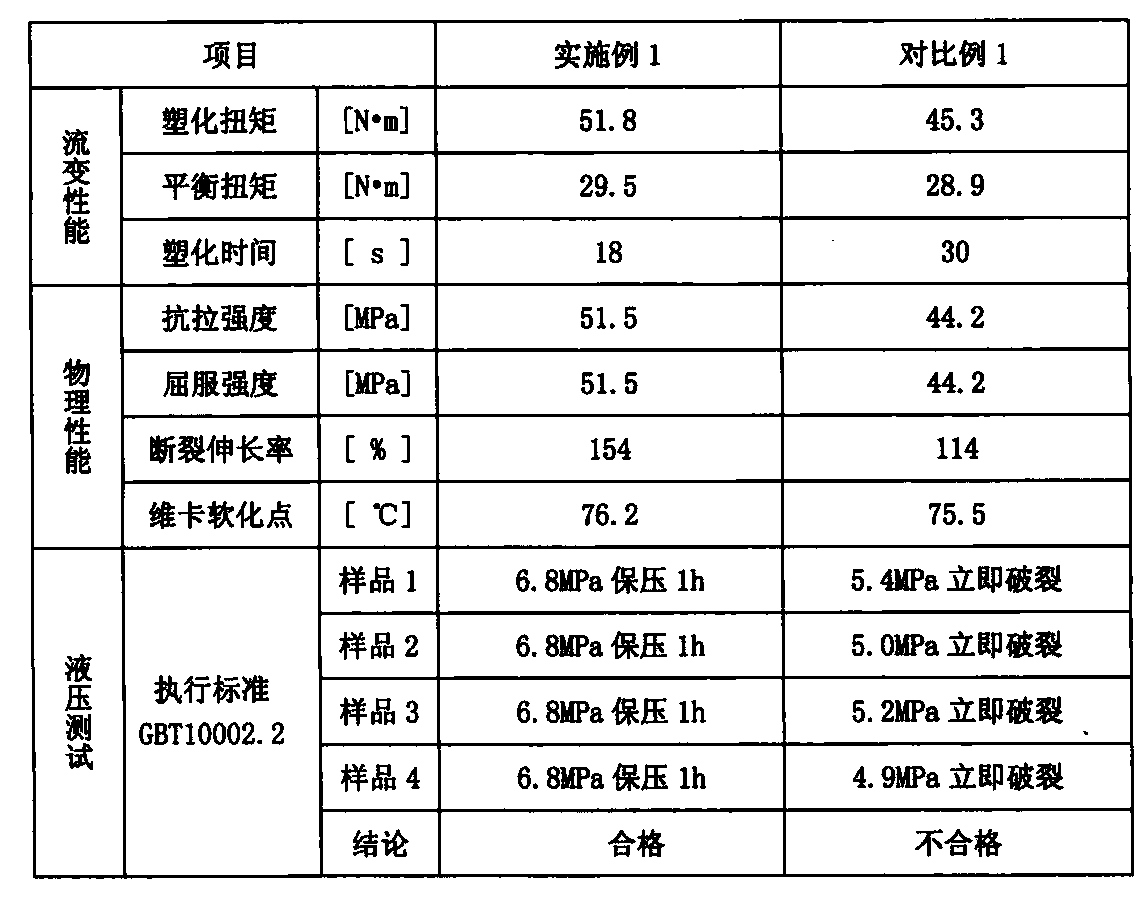

Embodiment 1

[0026] The raw materials in the following parts by mass are uniformly mixed by a high-speed mixer, and then molded by an injection molding machine at a processing temperature of 160~190°C into a U-PVC water supply pipe fitting with a Φ75mm (inner diameter) tee for water supply of the national standard GBT10002.2.

[0027] Polyvinyl chloride resin PVC HG-800 (Hanwha Chemical) 100 parts;

[0028] Butyltin mercaptide (T395C, Arkema) 2.0 parts;

[0029] LOXIOL G72: 1.0 parts;

[0030] 0.6 parts of glyceryl mono and distearate;

[0031] 0.5 parts of calcium stearate;

[0032] 0.1 part of oxidized polyethylene wax;

[0033] HPA-40: 1.5 parts;

[0034] ACR LP-21: 0.8 parts;

[0035] MBS B564: 3.0 copies;

[0036] PP-G-MAH: 3.0 parts;

[0037] 2.2 parts of titanium dioxide;

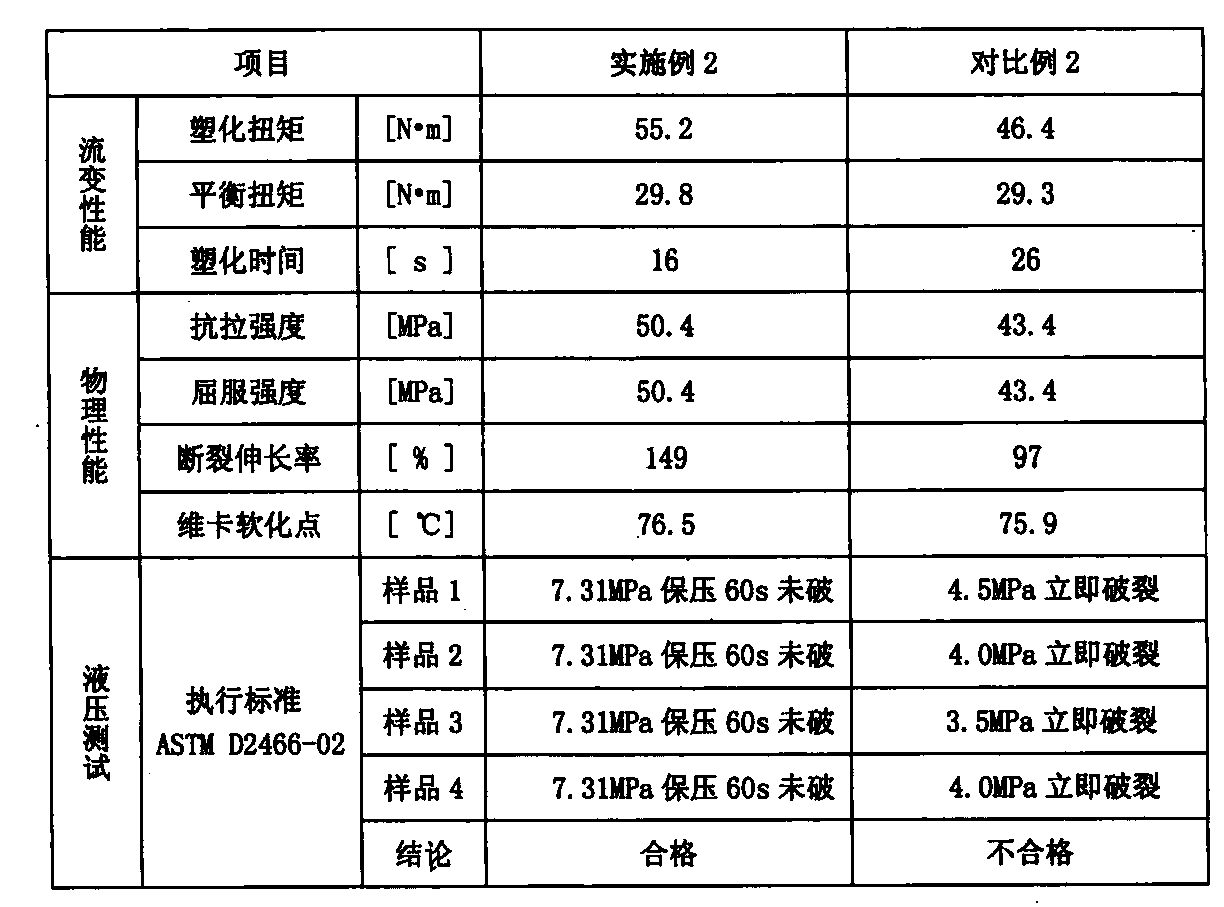

Embodiment 2

[0051] The raw materials in the following parts by mass are uniformly mixed by a high-speed mixer, and then injection molded by an injection molding machine at a processing temperature of 160~190°C into a Φ50mm (inner diameter) tee for water supply according to American Standard ASTM D2466-02.

[0052] PVC HG-800 (Hanwha Chemical): 100 parts;

[0053] Butyltin mercaptide (T395C, Arkema) 2.2 parts;

[0054] LOXIOL G72: 1.4 parts;

[0055] 0.5 parts of calcium stearate;

[0056] 0.6 parts of oxidized polyethylene wax;

[0057] HPA-40: 2.5 parts;

[0058] MBS B564: 5.0 copies;

[0059] PP-G-MAH: 4.0 parts;

[0060] 2.5 parts of titanium dioxide;

[0061] 30 parts of superfine activated calcium carbonate;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com