PLA (polylactic acid)/MMT (montmorillonite) degradation enhanced master batch blending modification PLA/PBAT (polyethylene terephthalate-adipic acid-butanediol copolyester) composite material and preparation method thereof

A technology for enhancing masterbatch and composite materials, applied in the field of biodegradable materials, can solve the problems of poor compatibility between polylactic acid and montmorillonite, and poor intercalation effect, so as to improve intercalation effect, improve compatibility, The effect of excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

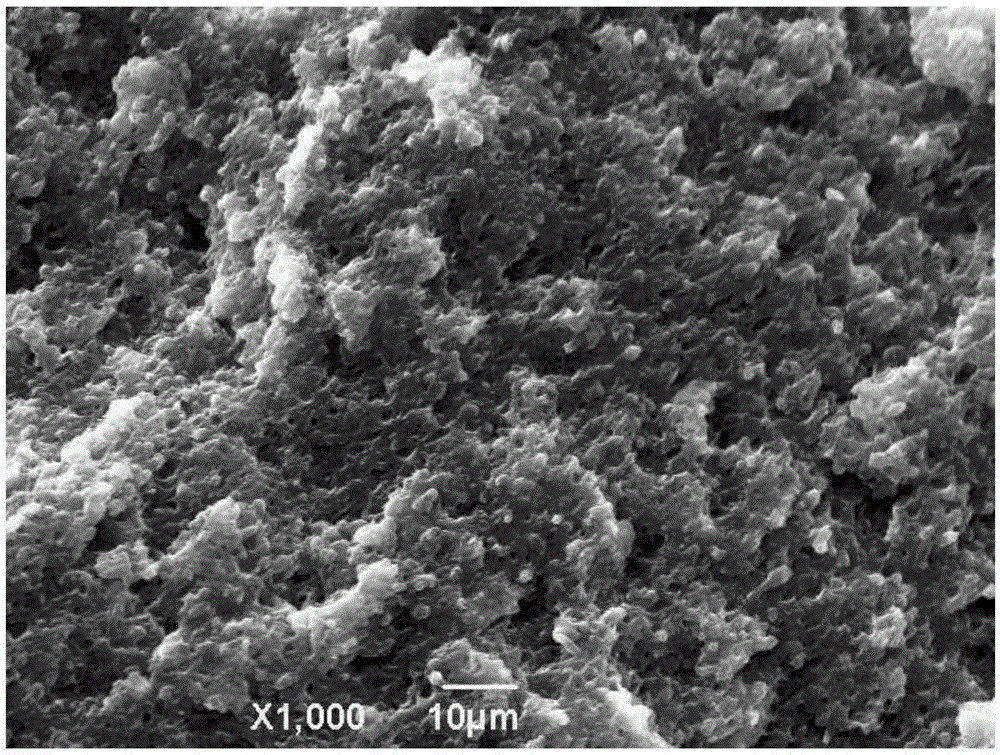

Image

Examples

Embodiment 1

[0037] A PLA / MMT degradation-enhancing masterbatch blended modified PLA / PBAT composite material in this embodiment, the modified PLA / PBAT composite material is prepared by in-situ polymerization of the following raw materials in parts by weight:

[0038] 10 parts of PLA / MMT degradation enhancement masterbatch

[0039] Polylactic acid PLA63 parts

[0040] 27 parts of polyterephthalic acid-adipic acid-butylene glycol copolyester PBAT.

[0041] The PLA / MMT degradation enhancing masterbatch blending modified PLA / PBAT composite material described above is prepared by the following method, including the following steps:

[0042] (1) Take 100 parts of sodium montmorillonite and 3500 parts of deionized water to make a suspension of sodium montmorillonite, adjust the pH of the suspension to pH=6 with dilute hydrochloric acid and sodium hydroxide solution, and then Slowly add 40 parts of cetyltrimethylammonium bromide, 123 parts of isopropanol, and 1666 parts of deionized water, then ...

Embodiment 2

[0050] A PLA / MMT degradation-enhancing masterbatch blended modified PLA / PBAT composite material in this embodiment, the modified PLA / PBAT composite material is prepared by in-situ polymerization of the following raw materials in parts by weight:

[0051] 20 parts of PLA / MMT degradation enhancement masterbatch

[0052] Polylactic acid PLA56 parts

[0053] 24 parts of polyterephthalic acid-adipic acid-butylene glycol copolyester PBAT.

[0054] The PLA / MMT degradation enhancing masterbatch blending modified PLA / PBAT composite material described above is prepared by the following method, including the following steps:

[0055] (1) Take 100 parts of sodium montmorillonite and 3500 parts of deionized water to make a suspension of sodium montmorillonite, adjust the pH of the suspension to pH=6 with dilute hydrochloric acid and sodium hydroxide solution, and then Slowly add 40 parts of cetyltrimethylammonium bromide, 123 parts of isopropanol, and 1666 parts of deionized water to the...

Embodiment 3

[0062] A PLA / MMT degradation-enhancing masterbatch blended modified PLA / PBAT composite material in this embodiment, the modified PLA / PBAT composite material is prepared by in-situ polymerization of the following raw materials in parts by weight:

[0063] PLA / MMT Degradation Enhanced Masterbatch 30 parts

[0064] Polylactic acid PLA49 parts

[0065] 21 parts of polyterephthalic acid-adipic acid-butylene glycol copolyester PBAT.

[0066] The PLA / MMT degradation enhancing masterbatch blending modified PLA / PBAT composite material described above is prepared by the following method, including the following steps:

[0067] (1) Take 100 parts of sodium montmorillonite and 3500 parts of deionized water to make a suspension of sodium montmorillonite, adjust the pH of the suspension to pH=6 with dilute hydrochloric acid and sodium hydroxide solution, and then Slowly add 40 parts of cetyltrimethylammonium bromide, 123 parts of isopropanol, and 1666 parts of deionized water to the suspe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com