Aramid fiber reinforced 3D graphene/epoxy resin composite material as well as preparation method and application thereof

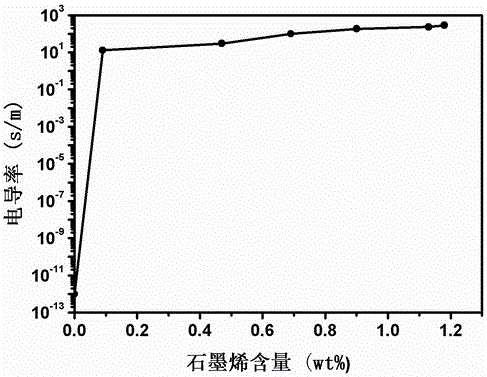

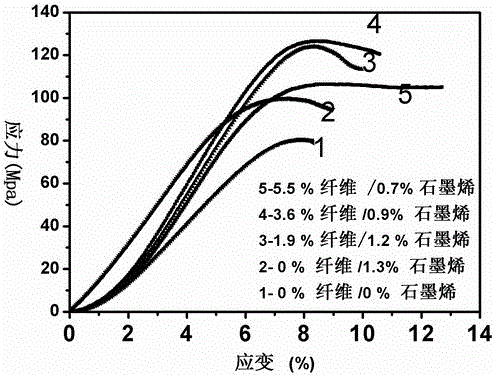

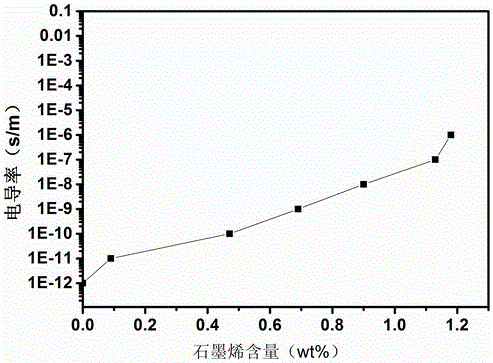

A kind of aramid fiber, composite material technology, applied in conductive materials dispersed in non-conductive inorganic materials, magnetic field/electric field shielding, electrical components, etc. , to achieve the effect of enhanced conductivity, high conductivity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Graphite oxide can be prepared by the following method: Add 300 mesh flake graphite into a 1000mL three-necked flask, put it in an ice bath, slowly add concentrated sulfuric acid and sodium nitrate, and keep stirring, keeping the temperature not higher than 5°C until it is completely dissolved. Add potassium permanganate, react the mixture in an oil bath at 35°C for 6 hours, stop stirring, then slowly add 460mL of deionized water to ensure that the temperature does not exceed 95°C, keep the mixture at 95°C for 15min, end the reaction, and mix the solution Move to a 2L beaker, add 1.4L of deionized water, stir for 2 hours, then slowly add 25mL of 30% hydrogen peroxide, let it stand overnight, remove excess potassium permanganate, and let it stand. (4) After the mixture settles, remove the supernatant, wash with a large amount of 5% HCl solution, then wash with water until neutral, centrifuge, and finally freeze-dry to obtain graphite oxide powder. According to the desire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com