Method for recycling multiple precious metals from anode mud

A rare precious metal, anode slime technology, applied in the improvement of process efficiency, photography process, instruments, etc., can solve problems such as large pollution, achieve the effect of solving arsenic pollution and solving the problem of excessive production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

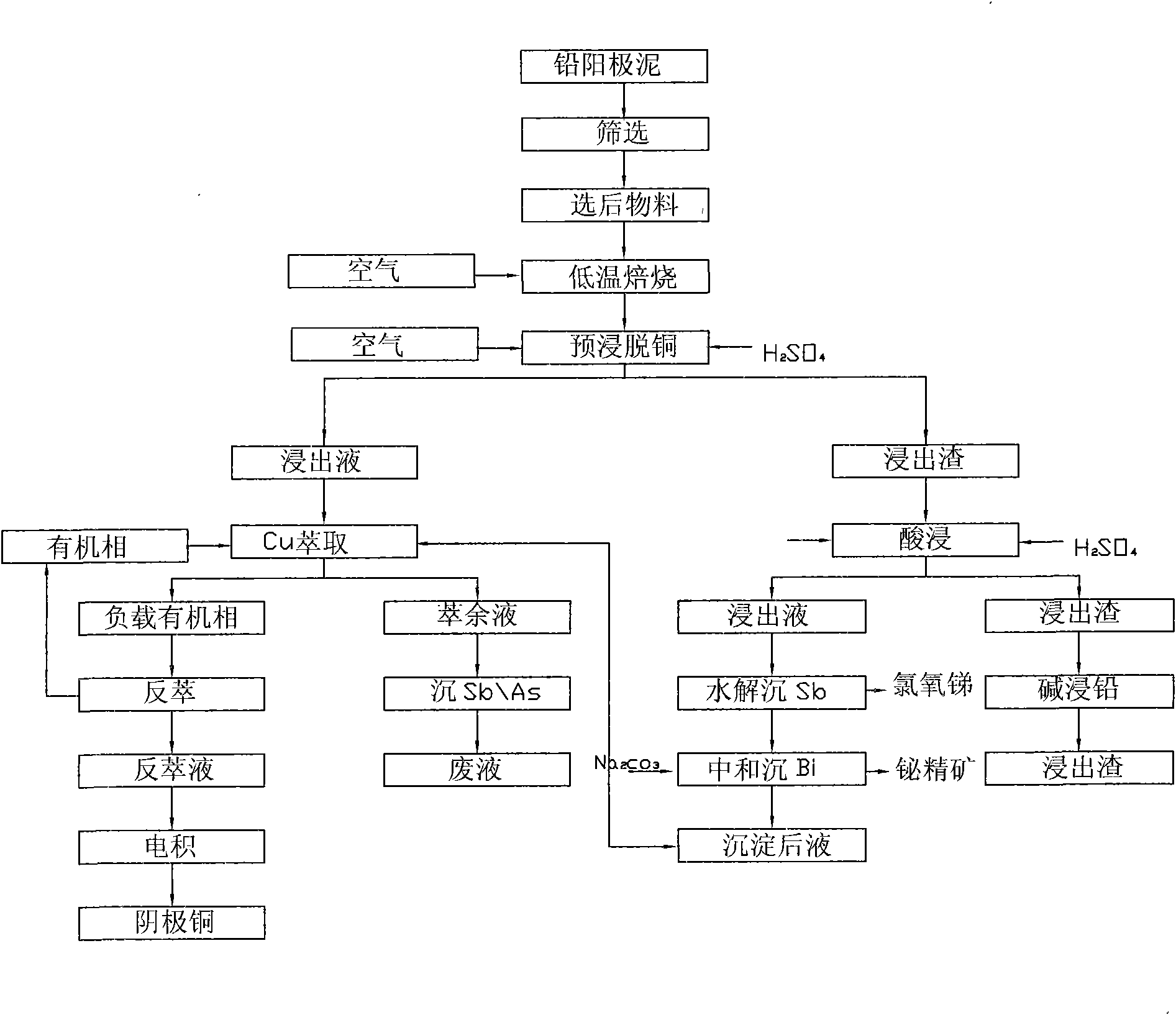

[0017] The technology of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018] Screening is carried out first, and screening is carried out by high-temperature smelting treatment of anode slime containing electrolyte in a smelting furnace, and the temperature is controlled at 1000-1100 degrees Celsius; the screened materials are sent to a low-temperature roasting furnace with a blower to add air and then roasted at a low temperature , the temperature is controlled at 500-600 degrees Celsius. After the roasted material is cooled, it enters the decopper tank for pre-soaking decopper. Sulfuric acid is added during the decopper process. There are electrodes in the decopper tank to control the pH value, and the pH value is controlled from 1- 2. The leaching solution and leaching slag are obtained through the decopper pre-preg treatment in the decopper pool.

[0019] The leaching slag obtained in the copper remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com