High-flux polyamide/ZIF-8 nanofiltration composite film and preparation method thereof

A ZIF-8 and polyamide nanotechnology, which is applied in the field of interfacial polymerization to prepare polyamide/ZIF-8 nanofiltration membranes, can solve problems such as defects, MOFs agglomeration interface, and affecting membrane separation performance, so as to improve membrane performance and make membranes The process is simple and feasible, and the effect of excellent selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a novel PA / ZIF-8 membrane used for separating aqueous solution by nanofiltration and a preparation method thereof. First, ZIF-8 particles are grown on the surface of the ultrafiltration bottom membrane by an in-situ growth method, and then a PA / ZIF-8 dense skin layer is prepared by an interface polymerization method, and the composite membrane is obtained through post-processing.

[0024] The prepared PA / ZIF-8 nanofiltration membrane uses a flat-panel membrane performance evaluation device to evaluate the separation performance of the separated aqueous solution system, that is, the permeation flux and rejection rate of the membrane.

[0025] 1) Osmotic flux ( J ), the permeability of the reaction membrane is defined as:

[0026] J = M / ( A · t ) or J = V / ( A · t )

[0027] In the formula, M and V respectively is the mass (kg) and volume (m) of permeate permeated through the membrane 3 ); A is the membrane area, m 2 ; t is the ...

Embodiment 1~4

[0032] 5.0 g Zn(NO 3 ) 2 ·6H 2 O was dissolved in a mixture of 100 mL methanol and 50 ml water to make Zn(NO 3 ) 2 ·6H 2 O solution, 15.0 g 2-methylimidazole was dissolved in 100 mL methanol to form a 2-methylimidazole solution; Zn(NO 3 ) 2 ·6H 2 The O solution was quickly poured into the 2-methylimidazole solution and stirred for 10 min to obtain a white ZIF-8 dispersion. The polyethersulfone ultrafiltration bottom membrane (30,000 Dal molecular weight cut-off) was immersed in the dispersion solution and allowed to stand at room temperature for 12 hours to allow ZIF-8 particles to grow on the bottom membrane surface. The bottom membrane was taken out, washed repeatedly with distilled water and methanol, and dried at 60 °C for 2 h to obtain the bottom membrane of a single growth of ZIF-8. Repeat the above ZIF-8 growth process to prepare the bottom membrane of ZIF-8 grown multiple times.

[0033] A flat-panel membrane performance evaluation device was used to evaluate ...

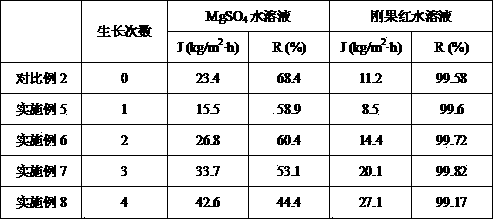

Embodiment 5-8

[0036]At room temperature, the TMC monomer was dissolved in n-hexane to prepare a 0.1% (w / v) organic phase solution, and the MPD monomer was dissolved in ultrapure water to prepare a 2% (w / v) aqueous phase solution. The ultrafiltration bottom membranes of Comparative Example 1 and Examples 1 to 4 were respectively selected and immersed in the MPD aqueous phase solution for 2 min, and the bottom membrane in the aqueous phase solution was removed to remove the excess water phase on the surface of the membrane; then the bottom membrane was placed on the The interfacial polymerization reaction occurred in the TMC organic phase solution for 20 s, took it out to dry in air, and heat-treated at 60 °C for 2 min, and finally washed repeatedly with deionized water to obtain the nanofiltration membrane.

[0037] The separation performance of the nanofiltration membrane separation aqueous solution system was measured by a flat-plate membrane performance evaluation device: the feed liquid w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com