Environment-friendly solar cell back film

A solar cell, environmentally friendly technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of poor fluoropolymer layer compactness, short storage time of fluororesin solution, environmental pollution, etc., and achieves low performance requirements, reducing Pollution and personal injury, the effect of reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

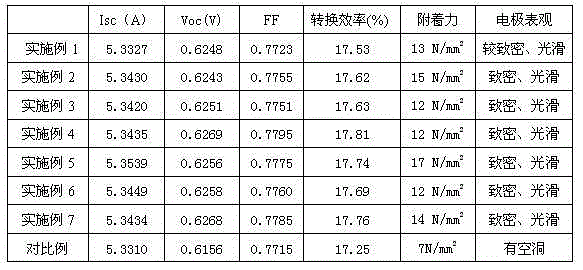

Examples

Embodiment 1

[0042] 15 parts of polyvinylidene fluoride (manufactured by Aldrich),

[0043] 5 parts of amine modified polyvinylidene fluoride-tetrafluoroethylene-hexafluoropropylene resin,

[0044] (Made by Lucky Film Co., Ltd. of China Lucky Film Group)

[0045] 7.5 parts of hydroxyl modified polyvinylidene fluoride-tetrafluoroethylene-hexafluoropropylene resin,

[0046] (Made by Lucky Film Co., Ltd. of China Lucky Film Group)

[0047] 1.5 parts of polytetrafluoroethylene powder (made by Solvay solexis),

[0048] 40 parts of water,

[0049] 1 part of N-methylpyrrolidone (manufactured by Nanjing Ruize Fine Chemical Co., Ltd.),

[0050] Add 40 parts of water to a container equipped with a stirring device, add 1 part of cosolvent N-methylpyrrolidone to the water and stir evenly, then add 15 parts of polyvinylidene fluoride and 5 parts of amine modified polyvinylidene fluoride Ethylene-tetrafluoroethylene-hexafluoropropylene resin, 7.5 parts of hydroxyl-modified polyvinylidene fluoride-tetrafluoroethylen...

Embodiment 2

[0053] 35 parts of polyvinylidene fluoride-tetrafluoroethylene-hexafluoropropylene,

[0054] (Made by Lucky Film Co., Ltd. of China Lucky Film Group)

[0055] 10 parts of carboxyl modified polyvinylidene fluoride-tetrafluoroethylene-hexafluoropropylene resin,

[0056] (Made by Lucky Film Co., Ltd. of China Lucky Film Group)

[0057] 8 parts of hydroxyl modified polyvinylidene fluoride-tetrafluoroethylene-hexafluoropropylene resin,

[0058] (Made by Lucky Film Co., Ltd. of China Lucky Film Group)

[0059] Acrylate polymer particles (made by Solvay solexis) 2.5 parts,

[0060] 70 parts of water,

[0061] 5 parts of dipropylene glycol methyl ether (manufactured by LyondellBasell),

[0062] Add 70 parts of deionized water into a container equipped with a stirring device, add 5 parts of co-solvent dipropylene glycol methyl ether into the water and stir evenly, then add 35 parts of polyvinylidene fluoride-tetrafluoroethylene-hexafluoropropylene, 10 parts Carboxyl modified polyvinylidene fluoride...

Embodiment 3

[0065] Polyvinylidene fluoride-hexafluoropropylene (3M Dyneon) 30 parts,

[0066] 8 parts of aziridine modified polyvinylidene fluoride-tetrafluoroethylene-hexafluoropropylene resin,

[0067] (Made by Lucky Film Co., Ltd. of China Lucky Film Group)

[0068] 12 parts of hydroxyl modified polyvinylidene fluoride-tetrafluoroethylene-hexafluoropropylene resin,

[0069] (Made by Lucky Film Co., Ltd. of China Lucky Film Group)

[0070] 3 parts of polyamide pellets (made by Solvay solexis),

[0071] 40 parts of water,

[0072] 4 parts of propylene glycol butyl ether (manufactured by Dow Chemical),

[0073] Add 40 parts of water to a container equipped with a stirring device, add 4 parts of cosolvent propylene glycol butyl ether into the water and stir evenly, then change 30 parts of polyvinylidene fluoride-hexafluoropropylene and 8 parts of aziridine to Polyvinylidene fluoride-tetrafluoroethylene-hexafluoropropylene resin, 12 parts of hydroxyl-modified polyvinylidene fluoride-tetrafluoroethylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com