Method for dispersing nano calcium carbonate powder material in aqueous solution

A technology of nano-calcium carbonate powder and body materials, which is applied in the field of oilfield chemistry, can solve the problems of nano-calcium carbonate particle size and ultrasonic dispersion, etc., and achieve the effect of obvious stabilization effect and promotion of dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The nano-calcium carbonate powder material used in this embodiment is produced by Henan Keli New Materials Co., Ltd. The solvent used in the experiment is distilled water, and the dispersant is compounded and used in combination with high-speed stirring and ultrasonic dispersion technology to disperse it.

[0043] The dispersant is composed of sodium dodecyl sulfate (SDS), OP-10 emulsifier, cetyltrimethylammonium bromide (CTAB) according to the mass ratio of 1:2:2, and the stabilizer adopts biological Polymer xanthan gum (XC).

[0044] The main instruments used in the experiment: Tester electric distilled water device, GJD-B12K single-axis frequency conversion high-speed mixer, JCP-1118 Shanhe ultrasonic cleaning machine, Zetasizer-3000 colloidal particle size / potential tester.

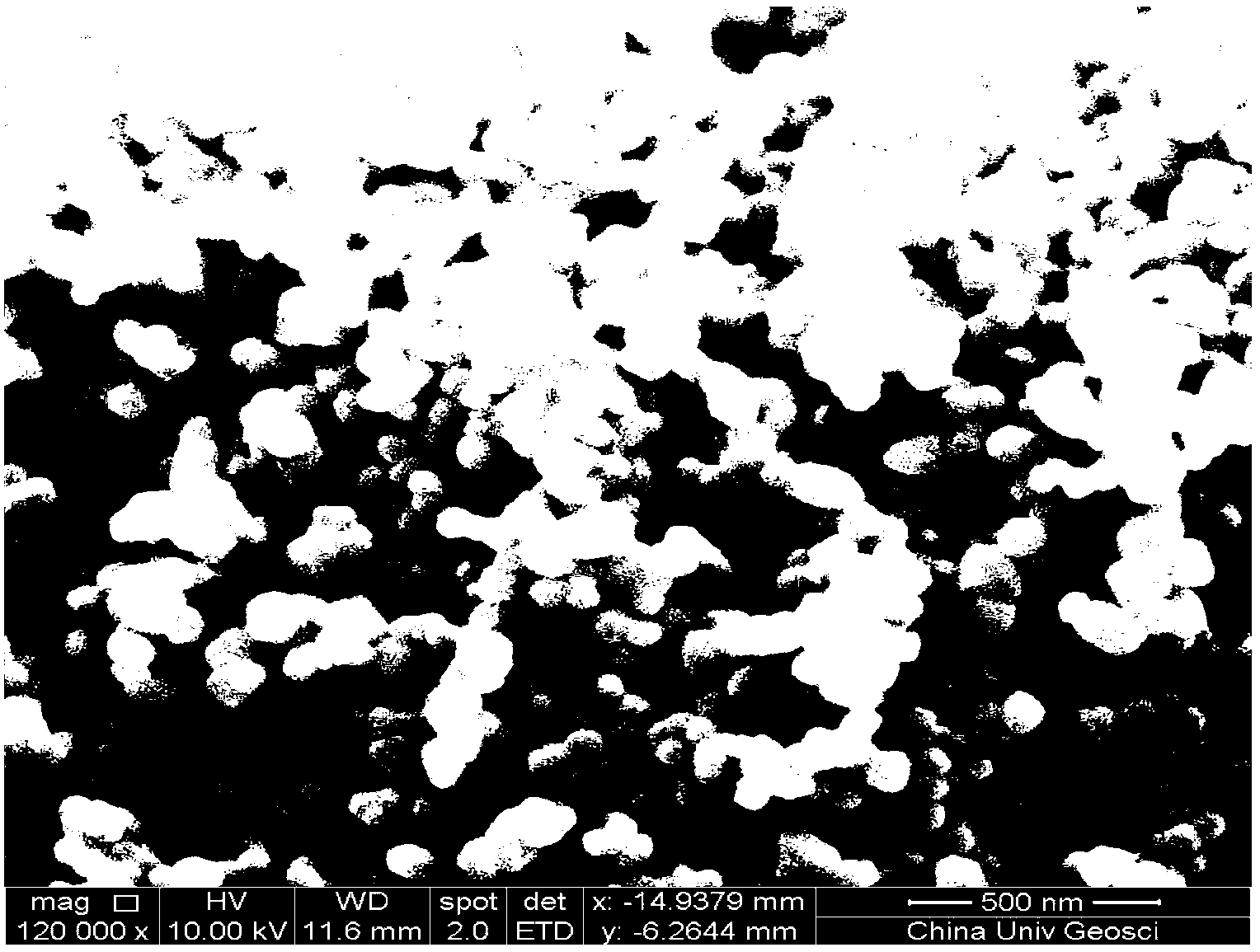

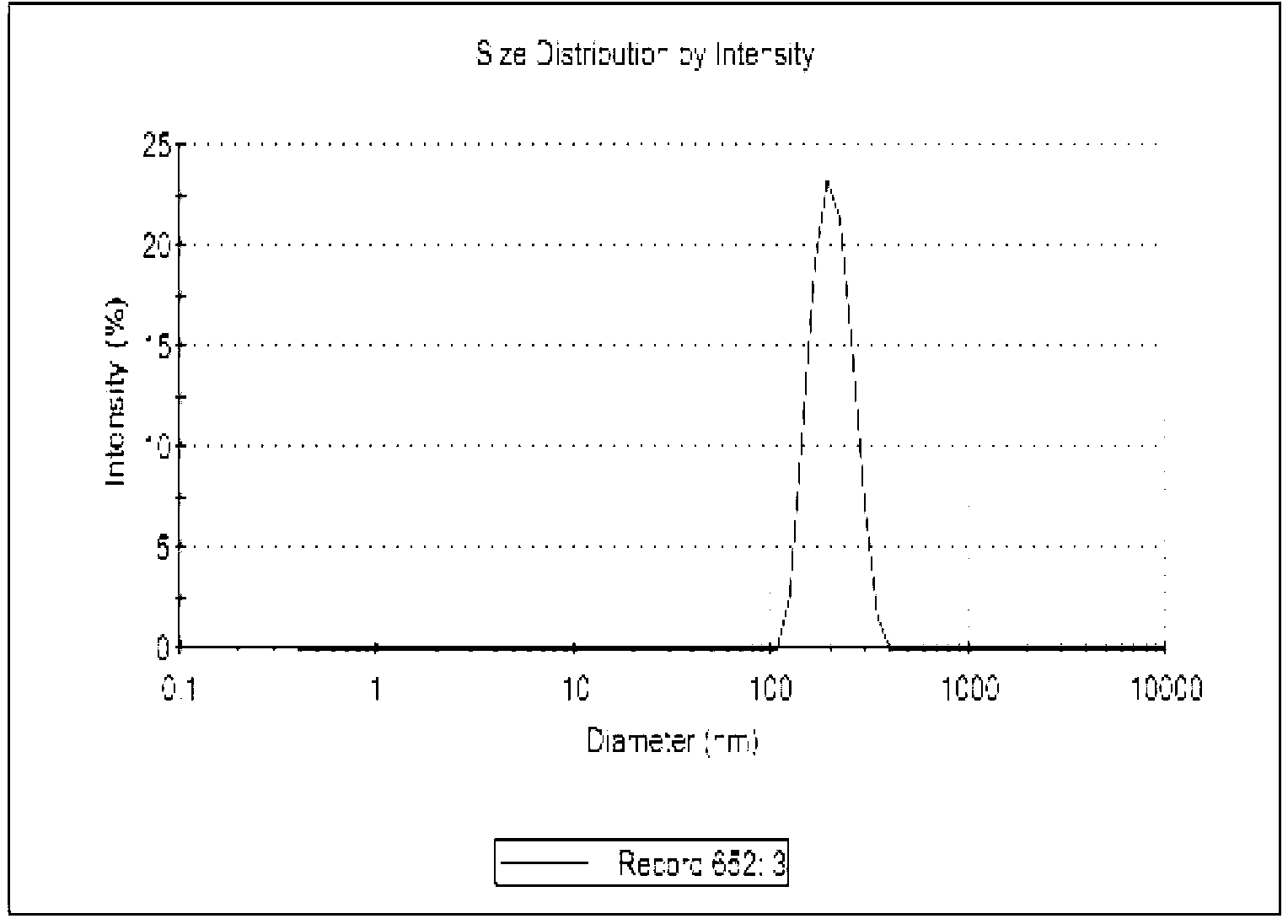

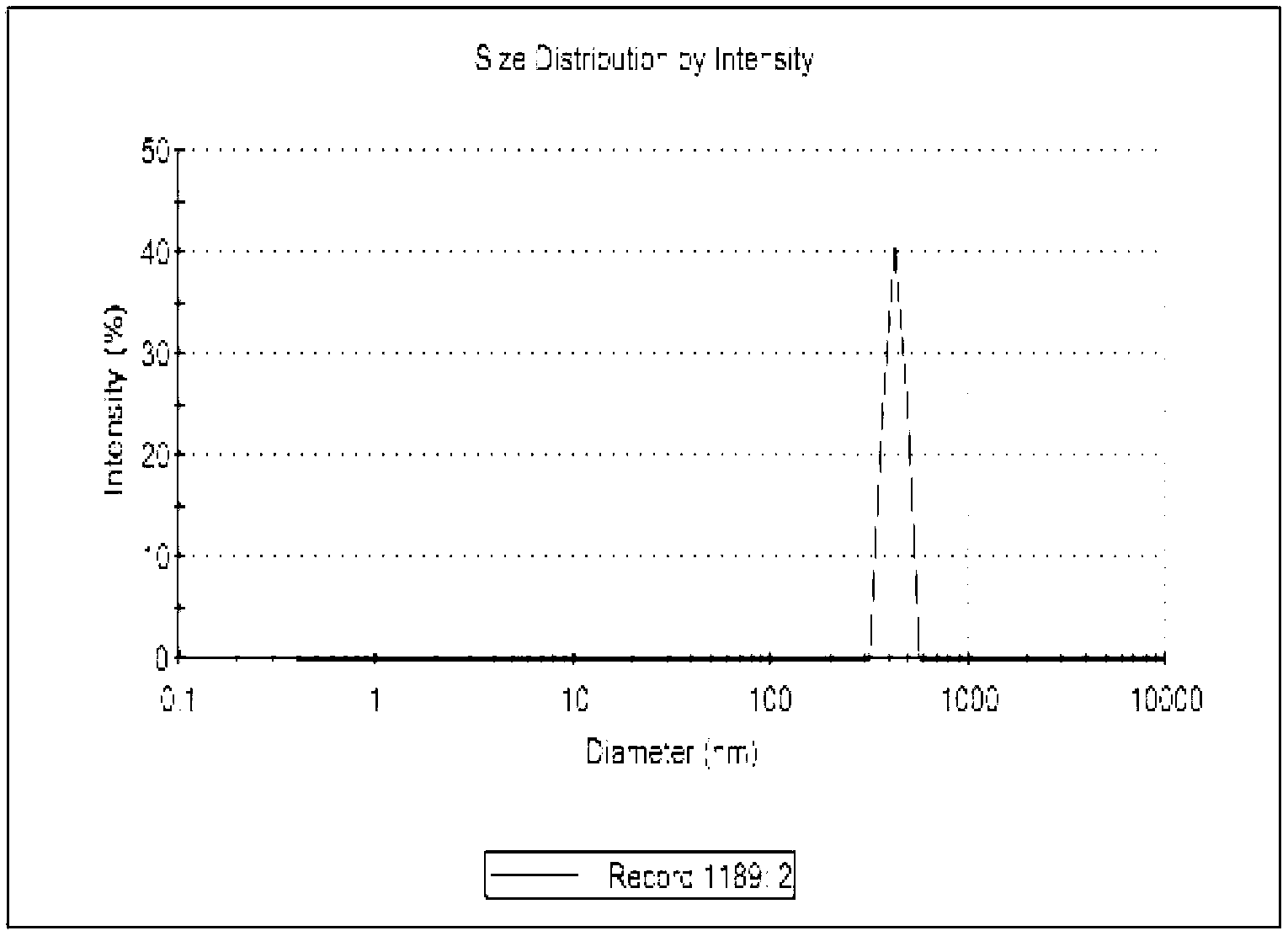

[0045] The results of scanning electron microscope (SEM) experiments show that the average particle size of nano-calcium carbonate produced by Henan Keli New Materials Co., Ltd. is about 50-60...

Embodiment 2

[0059] The nano-calcium carbonate used in this embodiment is produced by Hubei Kailong Chemical Group Co., Ltd. The solvent used in the experiment is distilled water, which is dispersed by using dispersant combined with high-speed stirring and ultrasonic dispersion technology.

[0060] The dispersant is composed of sodium dodecyl sulfate (SDS), OP-10 emulsifier, cetyltrimethylammonium bromide (CTAB) according to the mass ratio of 1:2:2, and the stabilizer adopts biological Polymer xanthan gum (XC).

[0061] The main instruments used in the experiment: Tester electric distilled water device, GJD-B12K single-axis frequency conversion high-speed mixer, JCP-1118 Shanhe ultrasonic cleaning machine, Zetasizer-3000 colloidal particle size / potential tester.

[0062] The results of scanning electron microscopy (SEM) experiments show that the average particle size of nano-calcium carbonate produced by Hubei Kailong Chemical Group Co., Ltd. is about 60-70nm.

[0063] The specific metho...

Embodiment 3

[0075] The nano-calcium carbonate used in this example is produced by Shanxi Ruicheng Xintai Nano Material Co., Ltd. The solvent used in the experiment is distilled water, which is dispersed by using dispersant combined with high-speed stirring and ultrasonic dispersion technology.

[0076] The dispersant is composed of sodium dodecyl sulfate (SDS), OP-10 emulsifier, cetyltrimethylammonium bromide (CTAB) according to the mass ratio of 1:2:2, and the stabilizer adopts biological Polymer xanthan gum (XC).

[0077] The main instruments used in the experiment: Tester electric distilled water device, GJD-B12K single-axis frequency conversion high-speed mixer, JCP-1118 Shanhe ultrasonic cleaning machine, Zetasizer-3000 colloidal particle size / potential tester.

[0078] The results of scanning electron microscopy (SEM) experiments show that the average particle size of nano-calcium carbonate produced by Shanxi Ruicheng Xintai Nano Material Co., Ltd. is about 40-70nm.

[0079] The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com