Graphene thermal-conductive film/thermal-conductive silica gel film composite material with layered alternative structure and preparation method of composite material

A heat-conducting silica gel and alternating structure technology, applied in chemical instruments and methods, lamination, lamination devices, etc., can solve problems such as difficulty in forming a stable and continuous heat conduction path, difficulty in graphene dispersion, etc., to improve tear resistance and mechanical properties Performance, excellent mechanical properties, good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

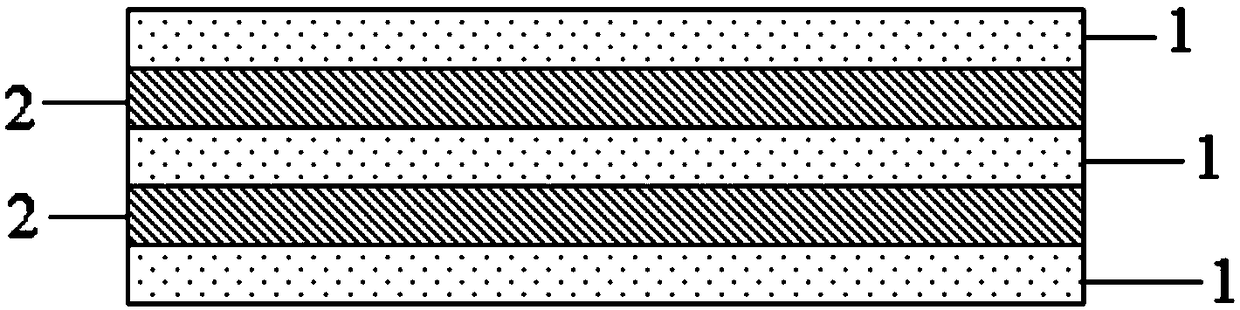

[0026] Specific embodiment one: This embodiment is a graphene thermally conductive film / thermally conductive silica gel film composite material with a layered alternating structure, specifically composed of a graphene thermally conductive film and a thermally conductive silica gel film, the graphene thermally conductive film and thermally conductive silica gel The films are arranged alternately; the thickness of the heat-conducting silica film is 0.1 mm to 10 mm.

specific Embodiment approach 2

[0027] Specific embodiment two: this embodiment is the preparation method of the graphene heat-conducting film / heat-conducting silica gel film composite material of layered alternating structure in the specific embodiment one, specifically carry out according to the following steps::

[0028] 1. Preparation of graphene thermal conductive film: Use a high-speed mixer to uniformly mix the graphene oxide aqueous solution, reducing agent and nanocellulose for 5 minutes to 10 minutes, then ultrasonically treat for 20 minutes to 60 minutes, and then stand at a temperature of 60°C to 90°C Reduction reaction 2h~6h, suction filtration on the mixed fiber microporous membrane, wash the filter cake with ethanol and water alternately until the filtrate is neutral, after washing, the filter cake is dried at a temperature of 80℃~120℃ for 2h~6h, and the mixed The fiber microporous filter membrane and the filter cake are peeled off to obtain a graphene thermal conductivity film;

[0029] The c...

specific Embodiment approach 3

[0038] Embodiment 3: This embodiment is different from Embodiment 2 in that: the reducing agent described in step 1 is hydrazine hydrate, sodium borohydride, hydroiodic acid or vitamin C. Others are the same as the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com