An embedded microfluidic printed circuit board compatible with various blind slots and its preparation method

A printed circuit board, micro-channel technology, applied in the direction of printed circuit manufacturing, printed circuits, printed circuit components, etc., to achieve efficient and uniform heat dissipation, reduce transmission loss and standing waves, and uniform heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

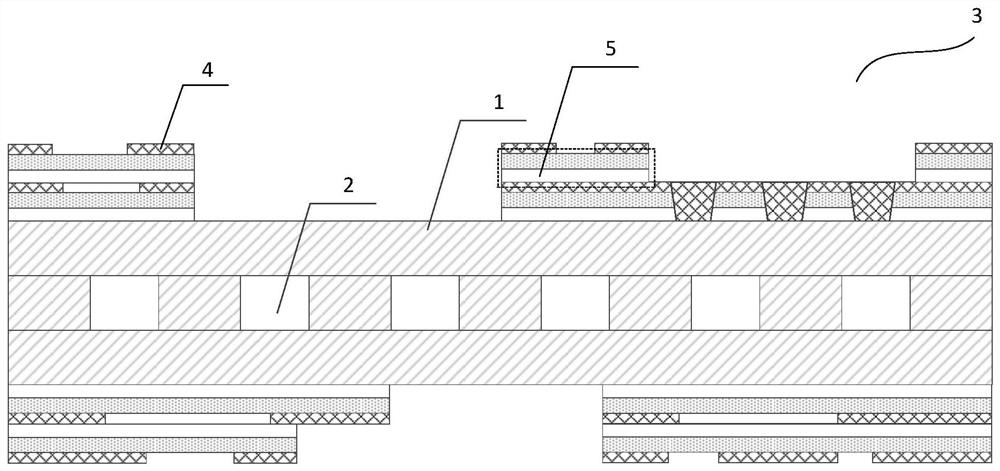

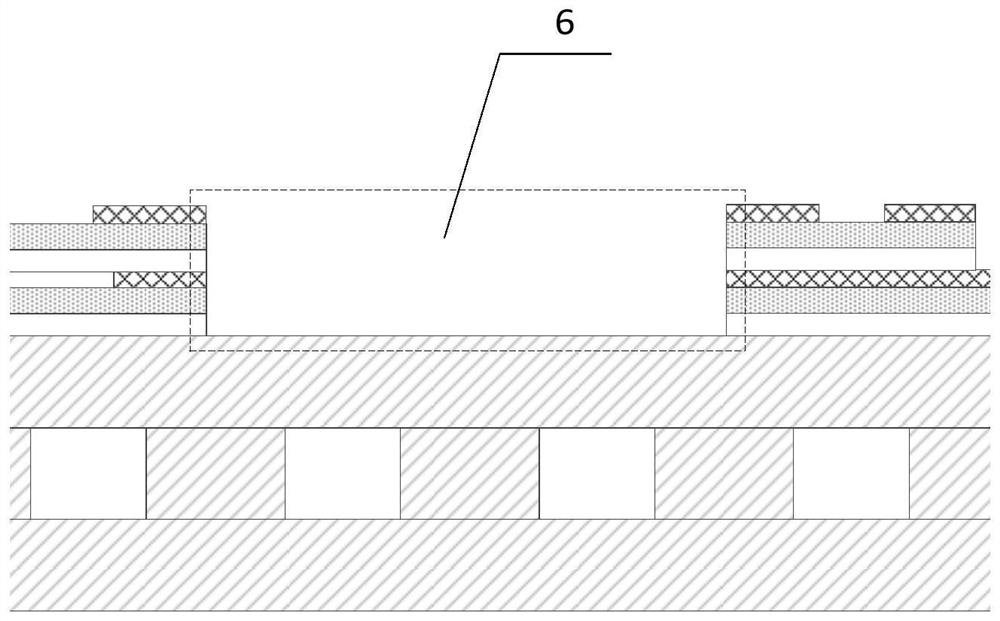

[0060] Such as figure 1 As shown, this embodiment proposes a printed circuit board 3 with embedded micro-channels compatible with various blind slots, including a metal core board 1 with embedded micro-channels 2, and multi-layer metal circuit layers located on both sides of the metal core board. 4 and the insulating medium layer 5, and a variety of heat dissipation blind slots with openings facing the surface metal circuit layer; the first heat dissipation blind slot 6, the second heat dissipation blind slot 7 and the third heat dissipation blind slot 8 are included. The present invention sets multiple heat dissipation blind slots to simultaneously meet heat dissipation demands of chips with different powers and thicknesses. Further, the insulating dielectric layer 5 is jointly composed of the dielectric layer of the prepreg 10 and the copper clad laminate 14 .

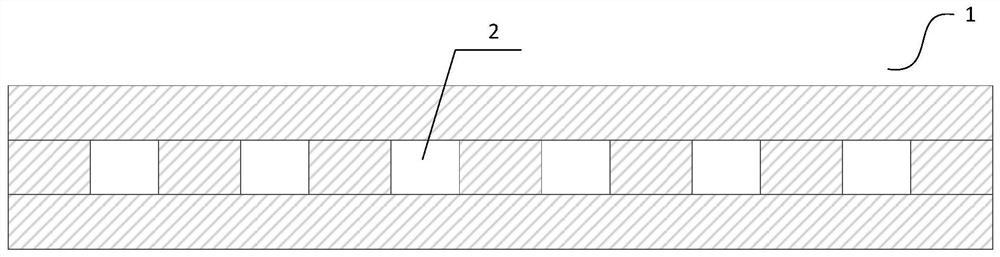

[0061] Such as figure 2 As shown, the material of the metal core plate 1 embedded with the micro-channel 2 is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com