Radiating fin group with improved structure

A heat dissipation fin group and heat dissipation single-chip technology, which is applied in the direction of cooling/ventilation/heating transformation, can solve the problems of low heat dissipation efficiency, difficulty in meeting heat dissipation requirements, and high production costs, and achieve high heat dissipation efficiency, high efficiency, and uniform heat dissipation. The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

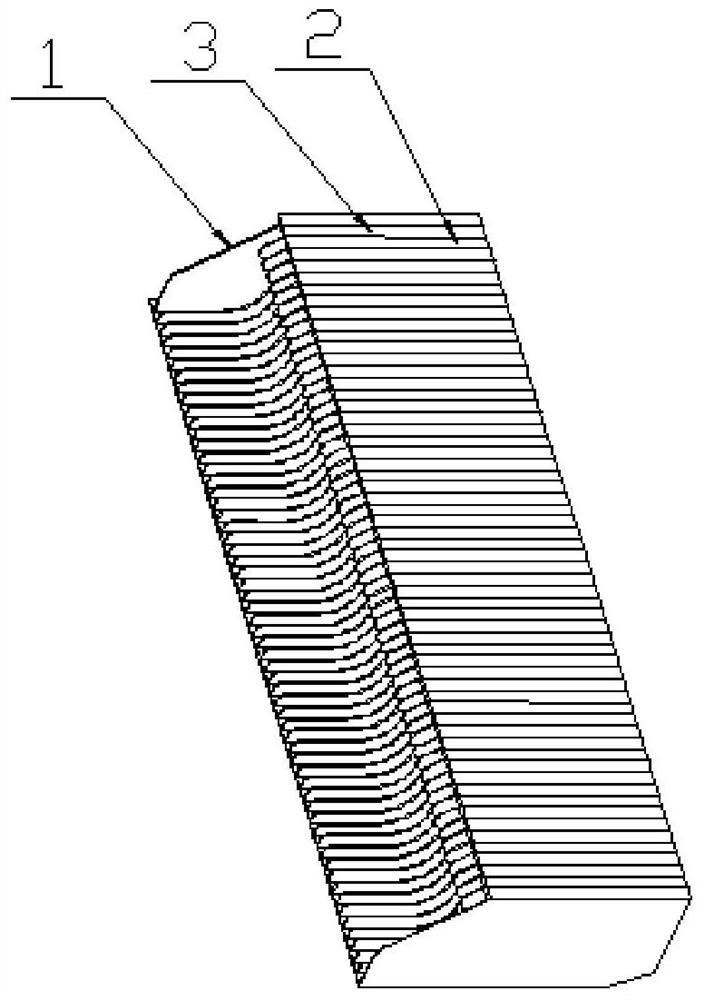

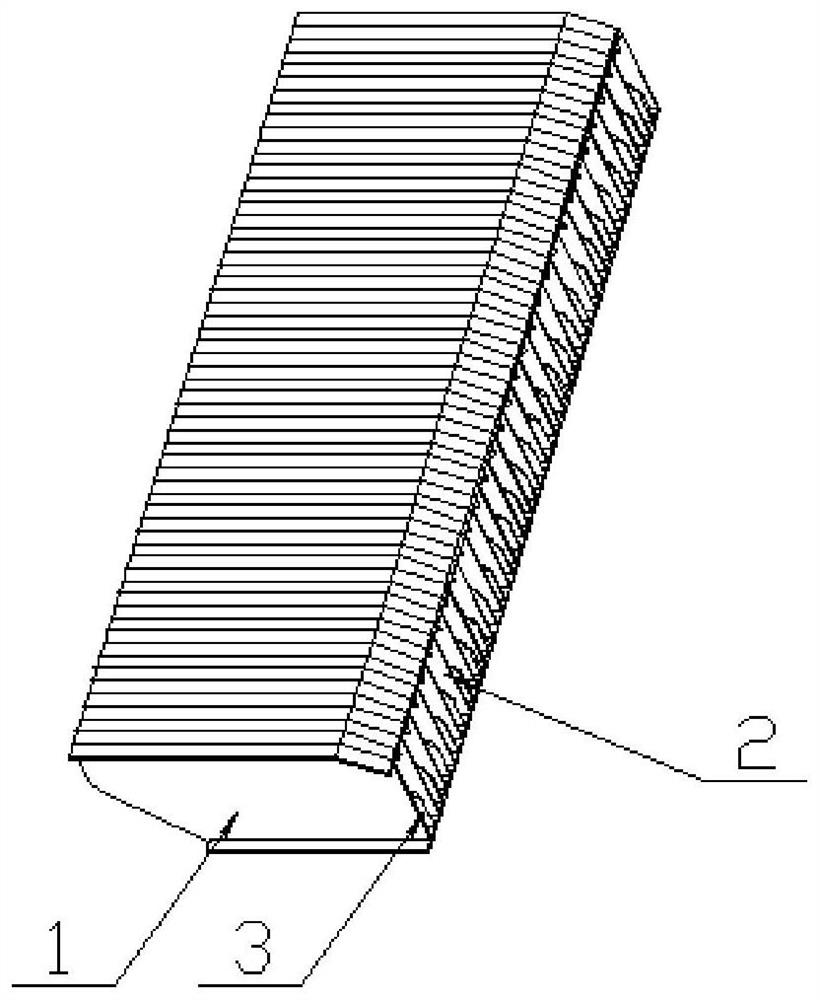

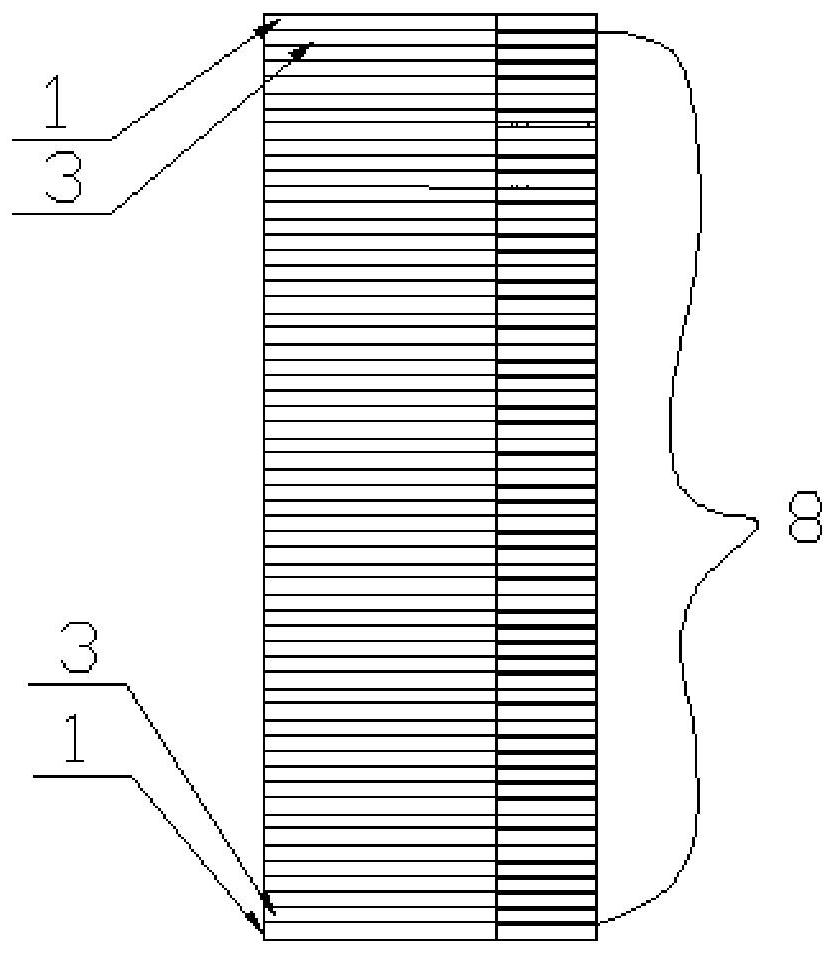

[0024] Embodiment: A heat dissipation fin group with improved structure, which is characterized by: comprising a first heat dissipation single piece 1, a second heat dissipation single piece 2 and a third heat dissipation single piece 3 in a U-shaped structure, and a plurality of second heat dissipation single pieces. 2 and the third heat-dissipating single piece 3 are alternately arranged and connected to form an intermediate heat-dissipating single-piece group 8 . The second heat dissipation single sheet 2 and the third heat dissipation single sheet 3 are formed with a first U-shaped opening 4 at one end of the bottom surface of the U-shaped structure.

[0025] The first heat dissipation single piece 1, the second heat dissipation single piece 2 and the third heat dissipation single piece 3 are stacked to form the entire heat dissipation fin group, a heat dissipation channel for airflow is formed between adjacent heat dissipation single pieces, and the heating element is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com