Diatom ooze capable of releasing anions and preparation method of diatom ooze

A technology of diatom mud and negative ions, which is applied in the field of decorative coatings, can solve the problems of reducing the utilization efficiency of photocatalyst decomposition materials, affecting the use effect, and agglomeration of nanomaterials, achieving good air purification effects, no secondary pollution, and good adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

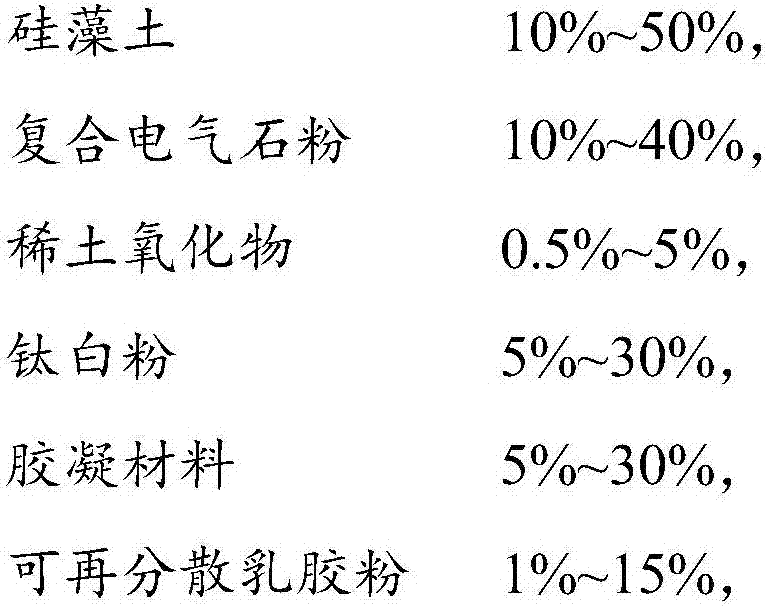

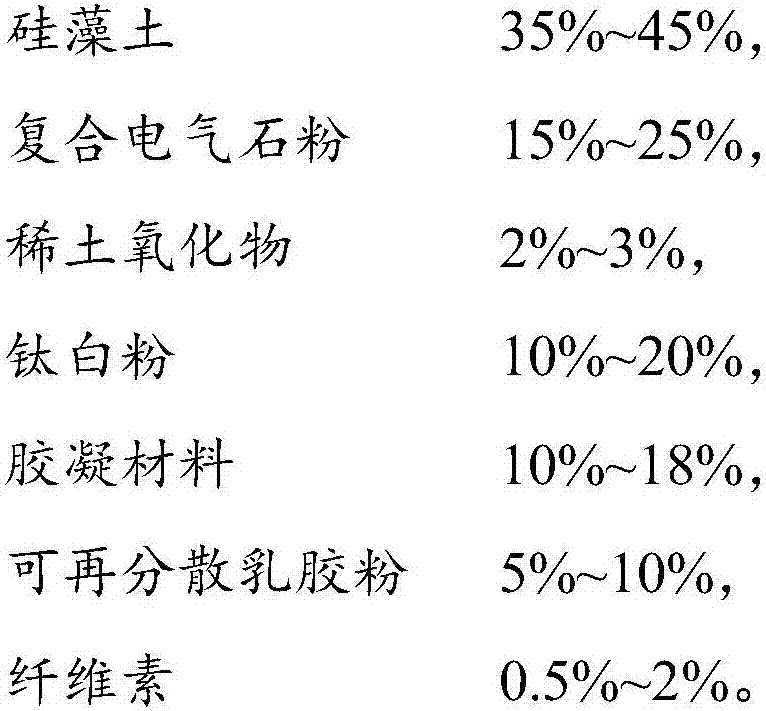

Method used

Image

Examples

Embodiment 1

[0046] The diatom ooze that releases negative ions in the present embodiment is prepared from the following raw materials by its weight percentage:

[0047]40% selected diatomite, 20% composite tourmaline powder, 2.5% rare earth oxide, 15% anatase titanium dioxide, 14% gelling material, 7% redispersible latex powder, 1.5% short cellulose ( The length is 1-3 mm); wherein the rare earth oxide is lanthanum oxide, and the cementitious material is wollastonite.

[0048] Composite tourmaline powder is prepared by the following methods:

[0049] a, dissolving 5g of sodium silicate in deionized water to obtain a sodium silicate solution with a mass concentration of 10%;

[0050] b. Disperse 0.7g surfactant (sodium dodecylbenzenesulfonate) evenly with 10g deionized water to obtain dispersion A, add dispersion A to the sodium silicate solution and disperse evenly to obtain dispersion B ;

[0051] c. Add 25g of nano-titanium dioxide to the dispersion B under constant temperature stirr...

Embodiment 2

[0058] The diatom ooze that releases negative ions in the present embodiment is prepared from the following raw materials by its weight percentage:

[0059] 45% selected diatomite, 15% composite tourmaline powder, 2% rare earth oxide, 20% anatase titanium dioxide, 10% gelling material, 6% redispersible latex powder, 2% short cellulose ( The length is 1-3 mm); wherein the rare earth oxide is cerium oxide, and the cementitious material is wollastonite.

[0060] The preparation method of composite tourmaline powder is with embodiment 1.

[0061] The negative ion-releasing diatom ooze of this example is prepared by the following method: Weigh the raw materials with an electronic weighing scale, add them into a dry grinder in proportion, and grind them thoroughly for 30 minutes to obtain the diatom ooze powder of this example.

[0062] The diatom mud powder material and water are mixed according to the ratio of 1:1.1 to form a paste slurry, which can be used.

Embodiment 3

[0064] The diatom ooze that releases negative ions in the present embodiment is prepared from the following raw materials by its weight percentage:

[0065] 35% selected diatomite, 25% composite tourmaline powder, 3% rare earth oxide, 20% anatase titanium dioxide, 11% gelling material, 5.5% redispersible latex powder, 0.5% short cellulose ( The length is 1-3 mm); wherein the rare earth oxide is yttrium oxide, and the cementitious material is wollastonite.

[0066] The preparation method of composite tourmaline powder is with embodiment 1.

[0067] The negative ion-releasing diatom ooze of this example is prepared by the following method: Weigh the raw materials with an electronic weighing scale, add them into a dry grinder in proportion, and grind them thoroughly for 40 minutes to obtain the diatom ooze powder material of this example.

[0068] The diatom mud powder material and water are mixed according to the ratio of 1:1.5 to form a paste slurry, which can be used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com