Homogeneous epitaxial lateral growth method for diamond

A technology of lateral growth and homoepitaxial growth, applied in the directions of single crystal growth, crystal growth, single crystal growth, etc., can solve the problem of low quality of diamond film, achieve the effect of reducing difficulty, improving film quality and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

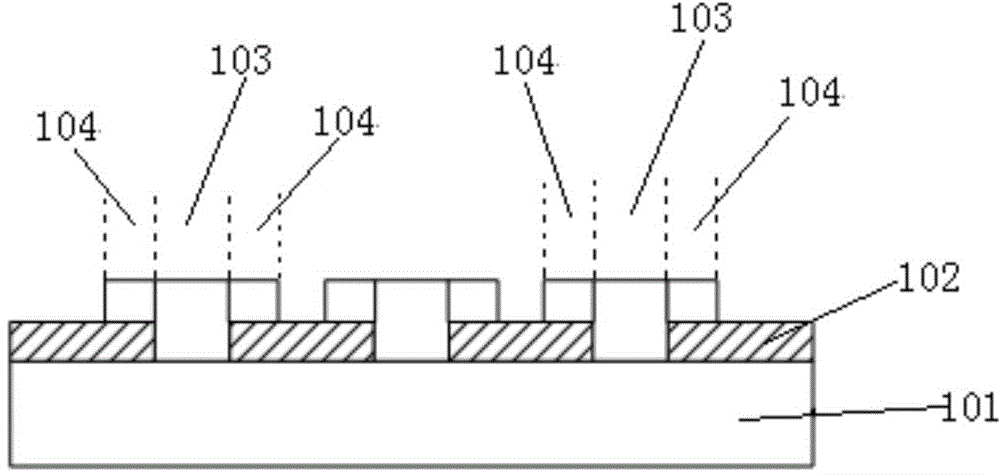

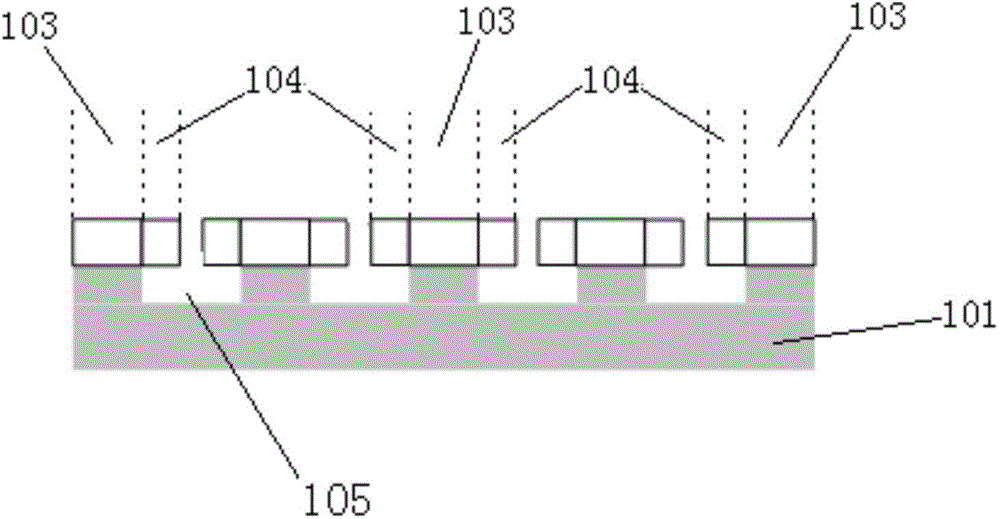

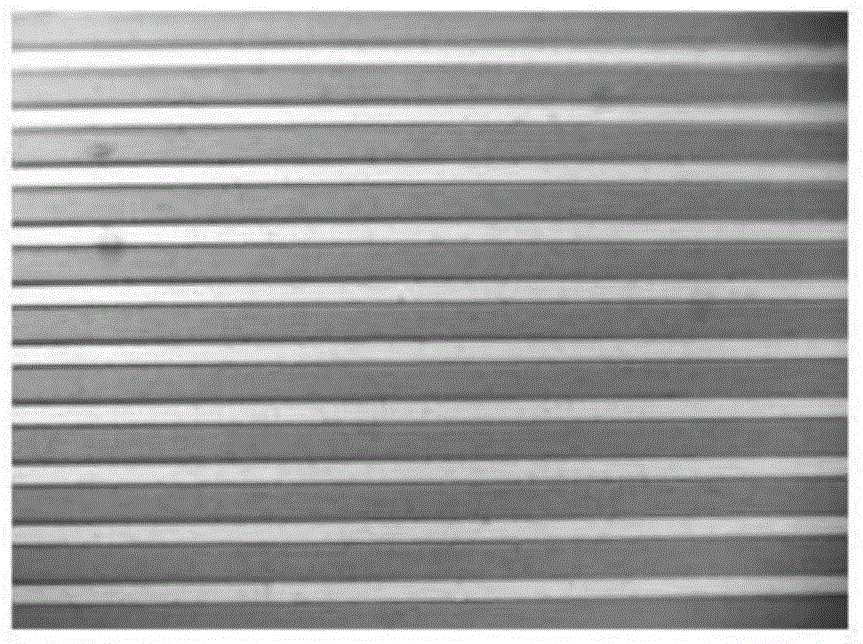

[0036] The invention provides a diamond homoepitaxial lateral growth method, which uses a photolithography process to pattern the mask deposited on the surface of a single crystal diamond substrate to form homoepitaxial growth and lateral growth regions, and then adopts CVD method in the Epitaxial growth is carried out on the patterned single-crystal diamond substrate, and finally a low-dislocation, high-quality, and smooth-surfaced single-crystal diamond film is grown. This method can also obtain the single-crystal diamond microstructure film required by MEMS and the like.

[0037] The diamond used as the substrate can be natural diamond or artificial diamond, but it must be single crystal diamond. In a single crystal diamond substrate, there are different crystal planes (100), crystal planes (111), etc., and there may also be tilt angles at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com