LED (light-emitting diode) radiating substrate based on diamond film and manufacturing method thereof

A technology of diamond thin film and heat dissipation substrate, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of complex heat dissipation structure manufacturing process, small air thermal conductivity, and limited heat dissipation effect, so as to reduce transmission distance and junction thermal resistance , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

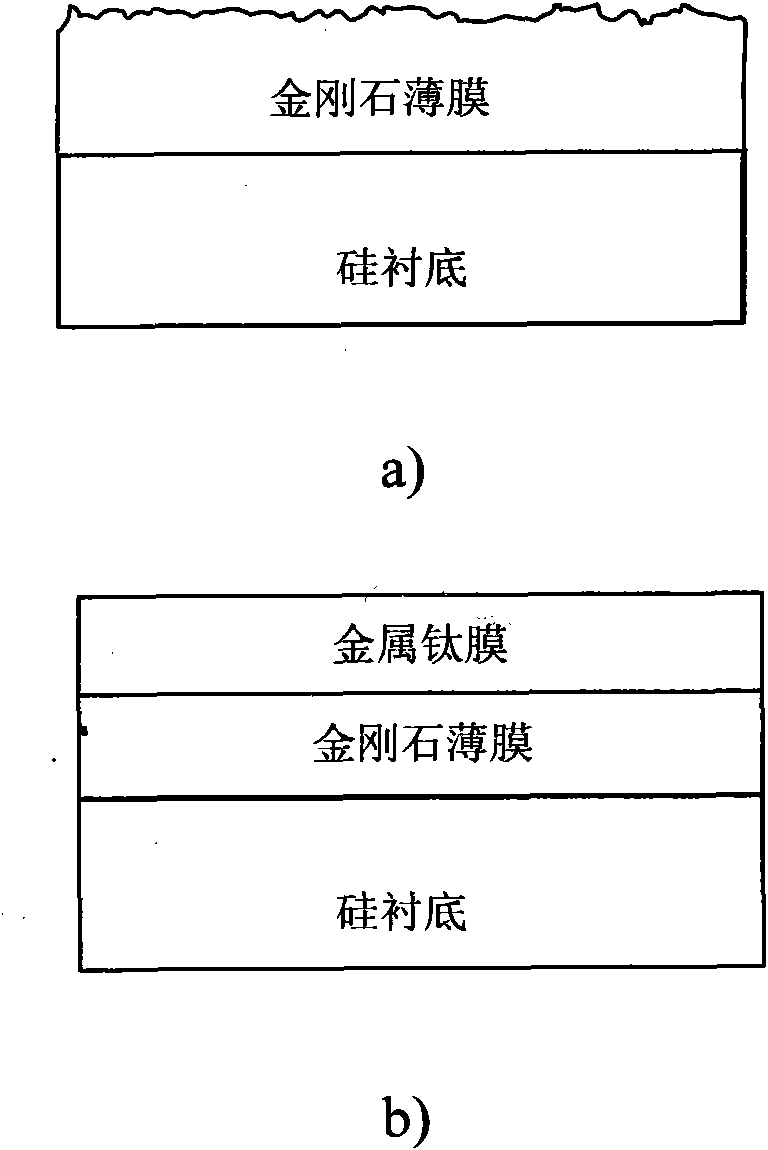

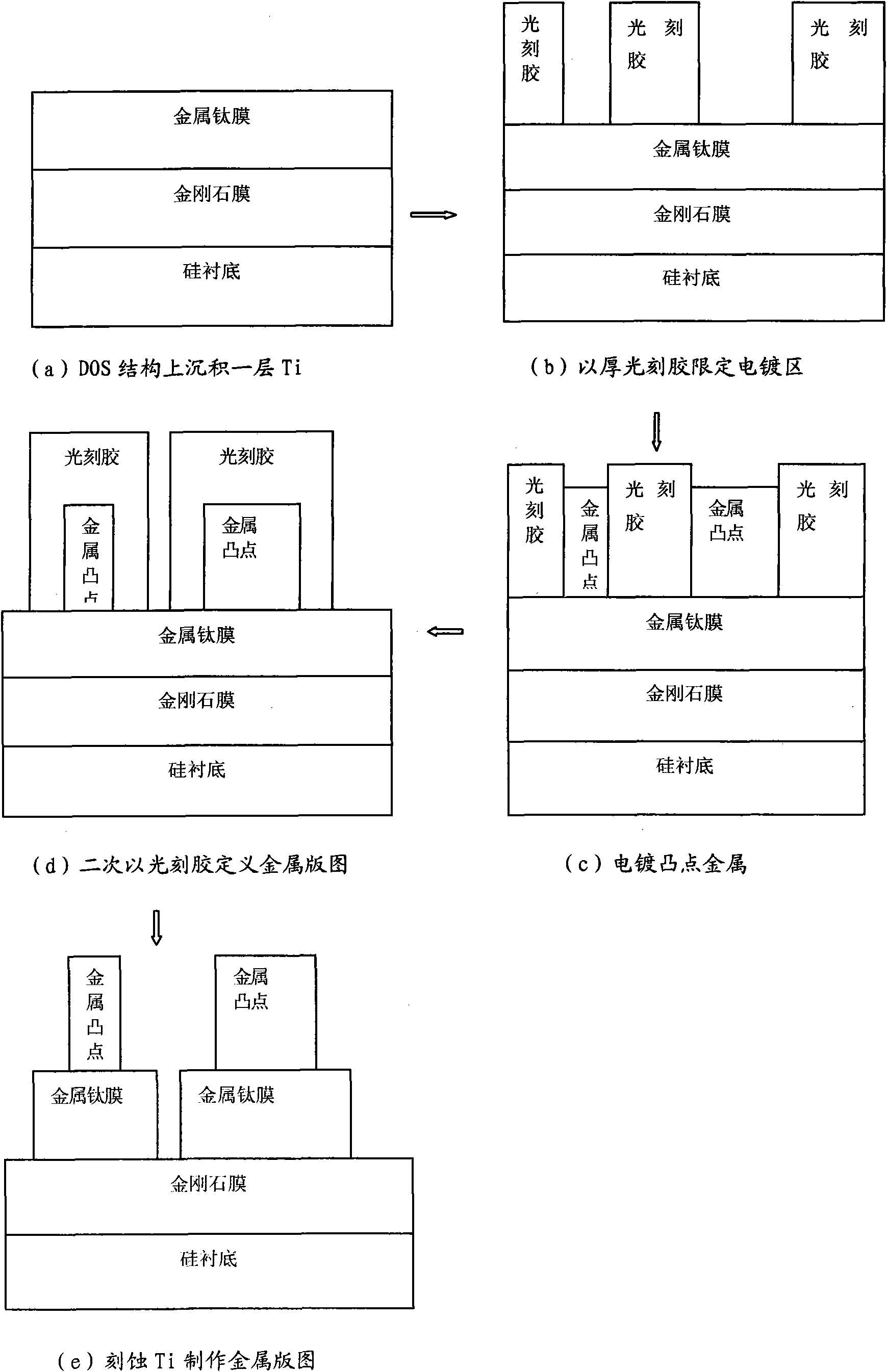

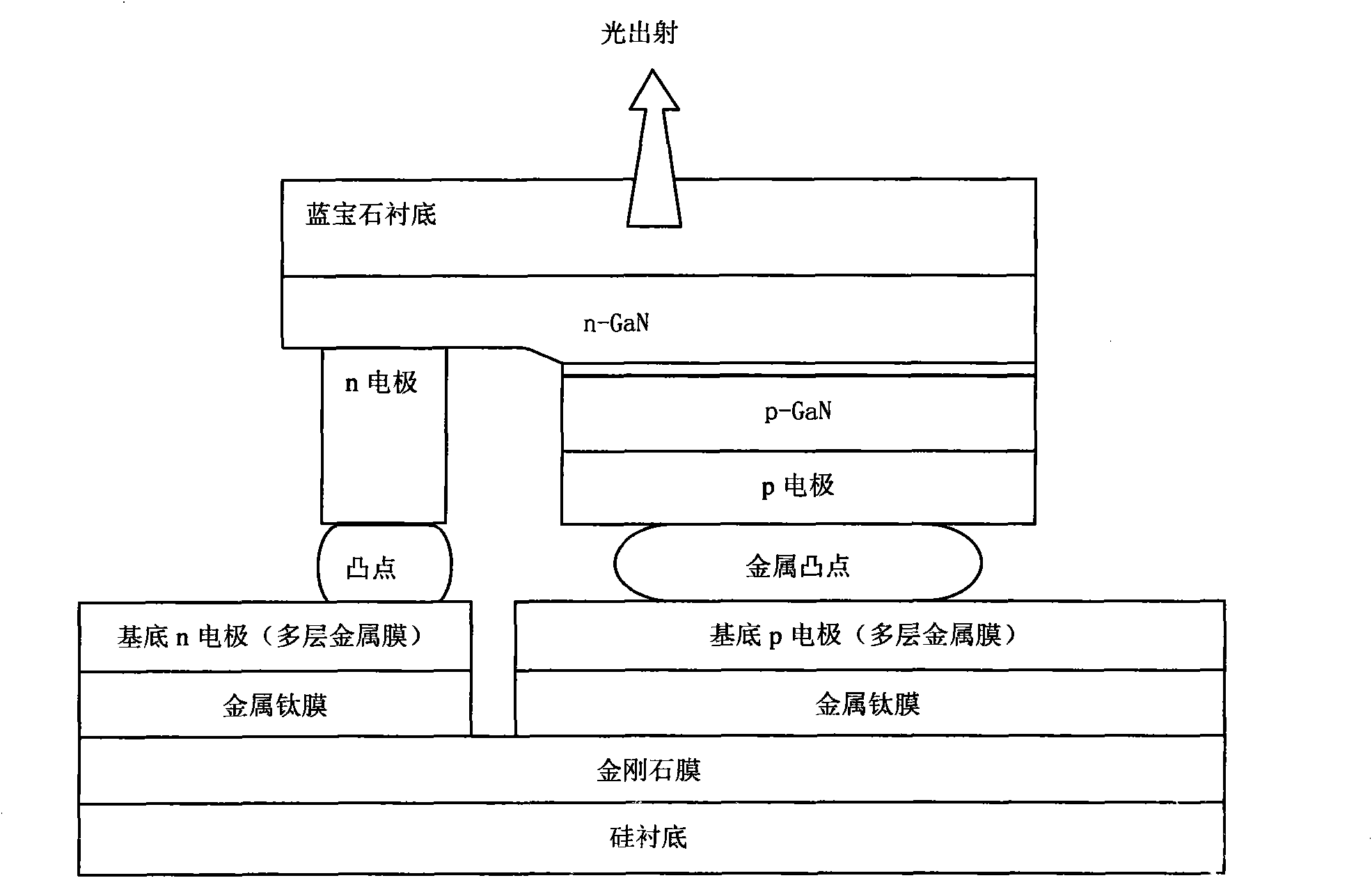

[0037] image 3 It is a cross-sectional view of the FC-LED structure using the DOS structure as the heat dissipation substrate in Embodiment 1, and its manufacturing process will be described in detail below.

[0038] The LED in Example 1 is a traditional GaN light-emitting diode with sapphire as the substrate. An epitaxial layer is grown on a sapphire substrate, and the epitaxial layer generally includes three layers: the upper layer is an n-GaN film, the lower layer is a p-GaN film, and the middle layer is an LED light-emitting active layer; a compound metal is deposited on the p-GaN of the epitaxial layer layer as a light-emitting reflective layer and electrode; etch away part of the p-type epitaxial layer and light-emitting active layer until the n-type layer is exposed, and then deposit an aluminum-based n-electrode contact on the exposed n-type GaN layer; on the p-type and n-type electrodes Make metal bumps for soldering.

[0039] The heat dissipation substrate for the...

Embodiment 2

[0048] Figure 4 It is a cross-sectional view of the TFFC-LED structure using DOS as the heat dissipation substrate in Embodiment 2, and the structure will be described in detail below.

[0049] Thin-film flip-chip LED structure (TFFC-LED) is to combine thin-film LED and flip-chip LED. The traditional LED substrate sapphire is removed with an excimer laser; the surface of the exposed n-type GaN layer is roughened with photoresist technology; then an n-type electrode is prepared on the n-GaN with a rough structure, and the wire Bond with the n-type electrode on the heat dissipation substrate, and finally connect the p-GaN of the vertical structure LED to another electrode of the heat dissipation substrate.

[0050] The manufacturing method of the heat dissipation substrate for the thin-film flip-chip LED structure is the same as that in Embodiment 1.

[0051] Flip-chip welding the prepared thin film LED to the prepared heat dissipation substrate. The flip-chip welding struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com