Cathode gas film microarc discharging method for preparing carbon nanometer material in solution

A technology of carbon nanomaterials and micro-arc discharge, which is applied in the field of preparation of carbon nanomaterials by ion electrolysis, can solve the problems of high energy consumption and achieve the effect of economical preparation and good environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Preparation of carbon nanomaterials using high-purity graphite electrodes

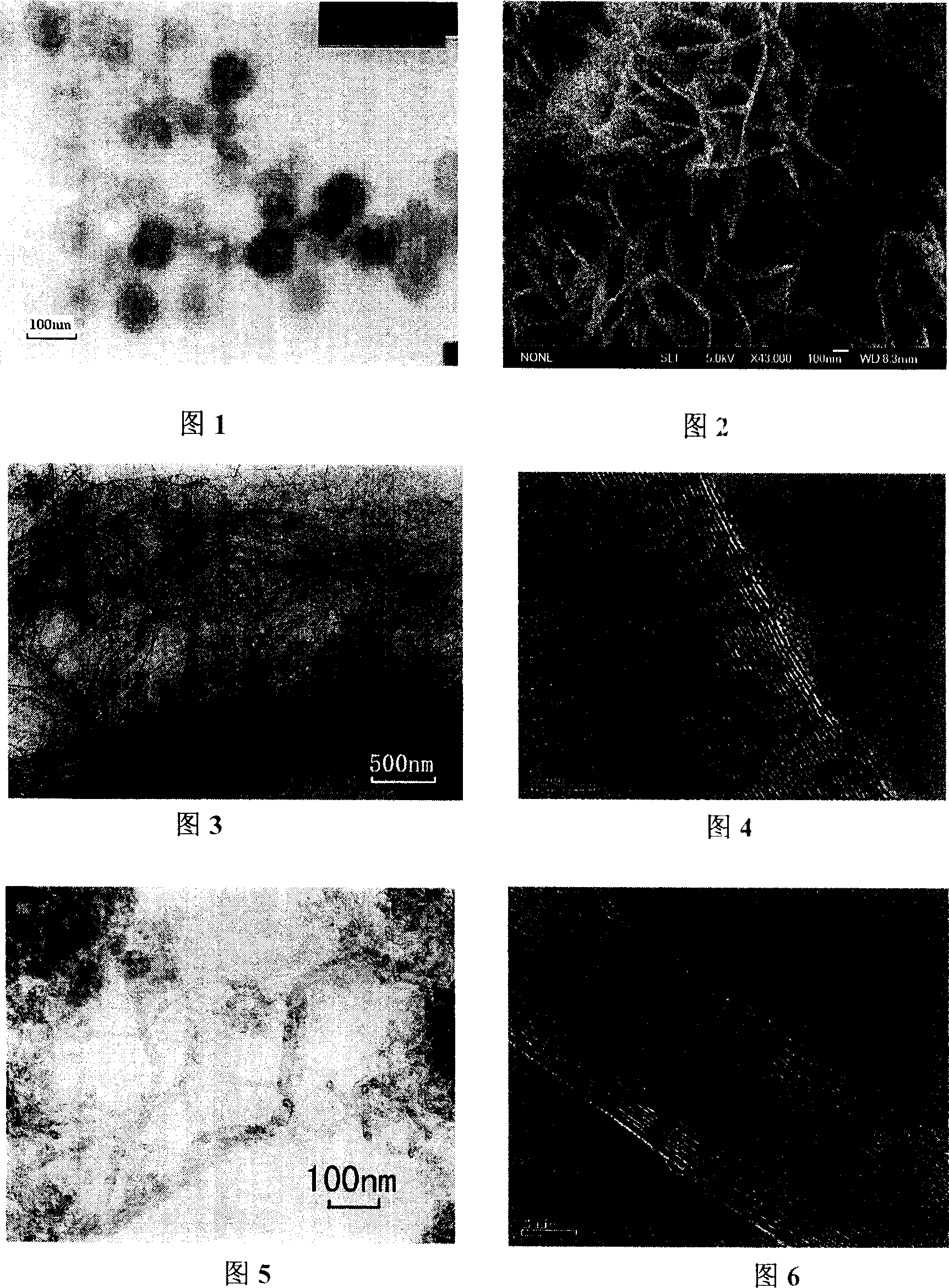

[0025] In 0.25mol / L of HCl, or H 2 SO 4 , or H 3 PO 4 , or KOH, or NaOH, or LiOH, or KCl, or NaCl, or LiCl aqueous solution, use a pure graphite rod with a diameter of 6mm as an electrode, and wrap its surface with a PTFE film so that the surface area of the cathode is 30mm 2 , the anode surface area is 60mm 2 , 15mm between cathode and anode, 130V direct current was applied, cathode micro-arc discharge occurred for 15min, and black precipitated crude product was obtained. After filtering the crude product, in 103°C, 4M HNO 3 Reflux for 1 hour, wash until neutral, and dry in air at 100°C for 1 hour. Carbon nanopowder and carbon nanoflowers can be obtained. Figure 1 and Figure 2 are the typical morphology of obtained carbon nanopowder and carbon nanoflower.

Embodiment 2

[0026] Embodiment 2: Preparation of carbon nanomaterials using graphite electrodes containing catalysts

[0027] In 0.25mol / L of HCl, or H 2 SO 4 , or H 3 PO 4 , or KOH, or NaOH, or LiOH, or KCl, or NaCl, or LiCl in an aqueous solution, using 5% Fe, or Co, or Ni, or Y, or their oxides, or their The high-purity graphite of the mixture is used as the cathode, and its diameter is 10mm, and its surface is wrapped with PTFE film, leaving 30mm 2 The surface area; the anode uses a pure graphite rod with a diameter of 6mm, and wraps its surface with a PTFE film, leaving 60mm 2 The surface area between the cathode and the anode is 30mm; a direct current of 180V is applied, and a cathode micro-arc voltage discharge occurs for 15min to obtain a black precipitated crude product. After filtering the crude product, in 103°C, 4M HNO 3 Reflux for 1 hour, wash until neutral, and dry in air at 100°C for 1 hour. Carbon nanofibers and carbon nanotubes are available. Figure 3 and Figure 4 ...

Embodiment 3

[0028] Embodiment 3: Preparation of carbon nanomaterials in aqueous solution containing organic matter

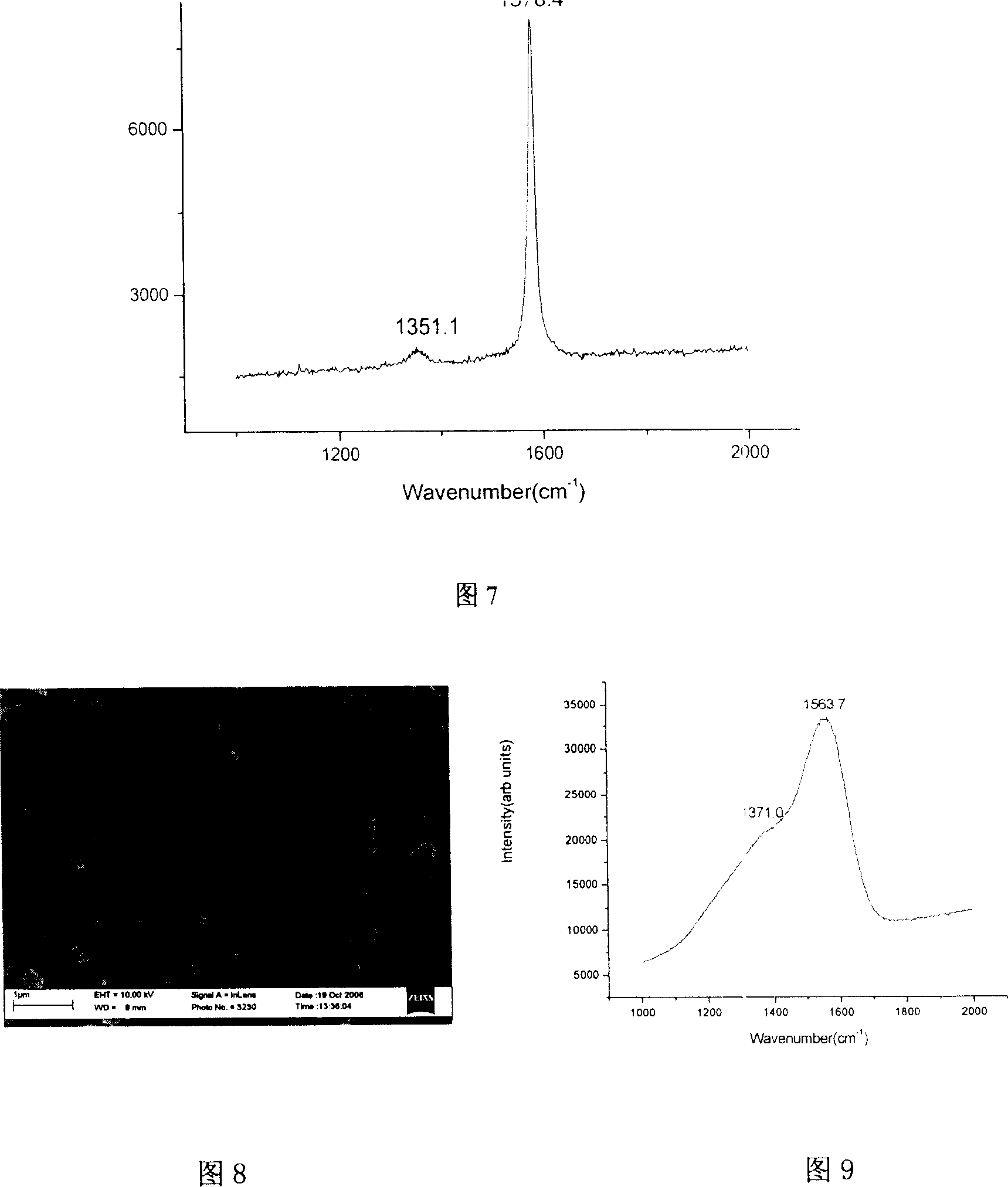

[0029] Platinum is used as the anode, nickel is the cathode, and the area ratio of the cathode and the anode is kept at 1.0, and the two electrodes are placed vertically in ethanol containing 50% by volume, or citric acid, or citrate, or 2-butenal, or In the 0.25mol / L NaCl aqueous solution of diethanolamine, the electrode spacing is fixed at 20mm, and a voltage of 110V is applied on the electrodes under the reflux state, and a cathode gas film micro-arc discharge occurs, which lasts for 15min, and the solution turns black, and the black in the solution After the product is pumped out, in 103°C, 4mol / L HNO 3 Reflux for 1 hour, after cooling, filter in a sand core funnel with a nylon filter membrane, wash until neutral, and dry in air at 100°C for 1 hour to obtain carbon nanotubes. Fig. 5, Fig. 6 and Fig. 7 are typical photographs of carbon nanotubes and analysis results of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com