Method for preparing diamond film through multiple-doped hot filament chemical vapor deposition

A technology of diamond thin film and hot wire chemistry, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of processing accuracy and surface finish, difficulty in grinding and polishing, and decrease in tool durability. Achieve the effect of improving insulation performance and smoothness, and facilitating adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

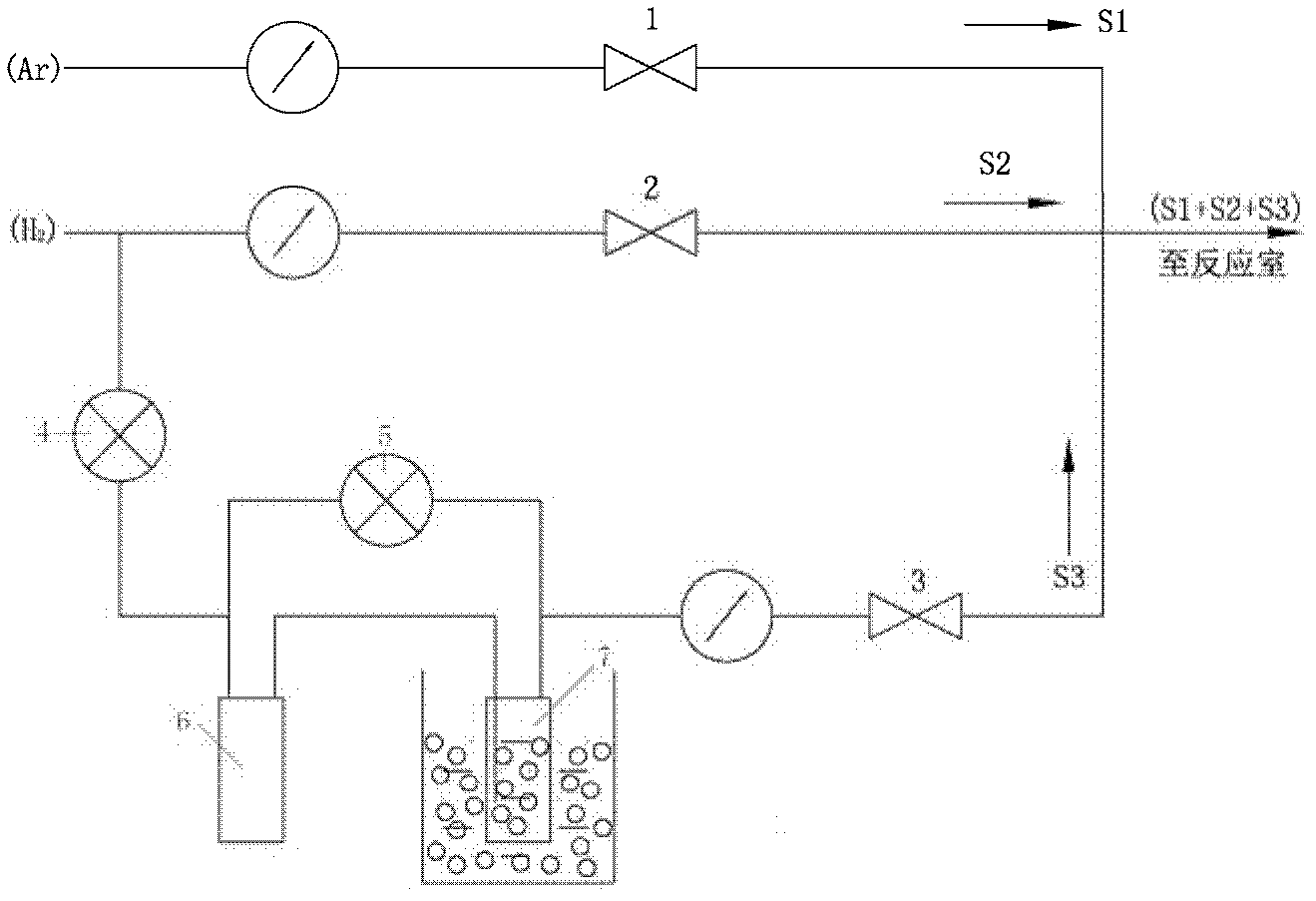

Method used

Image

Examples

Embodiment 1

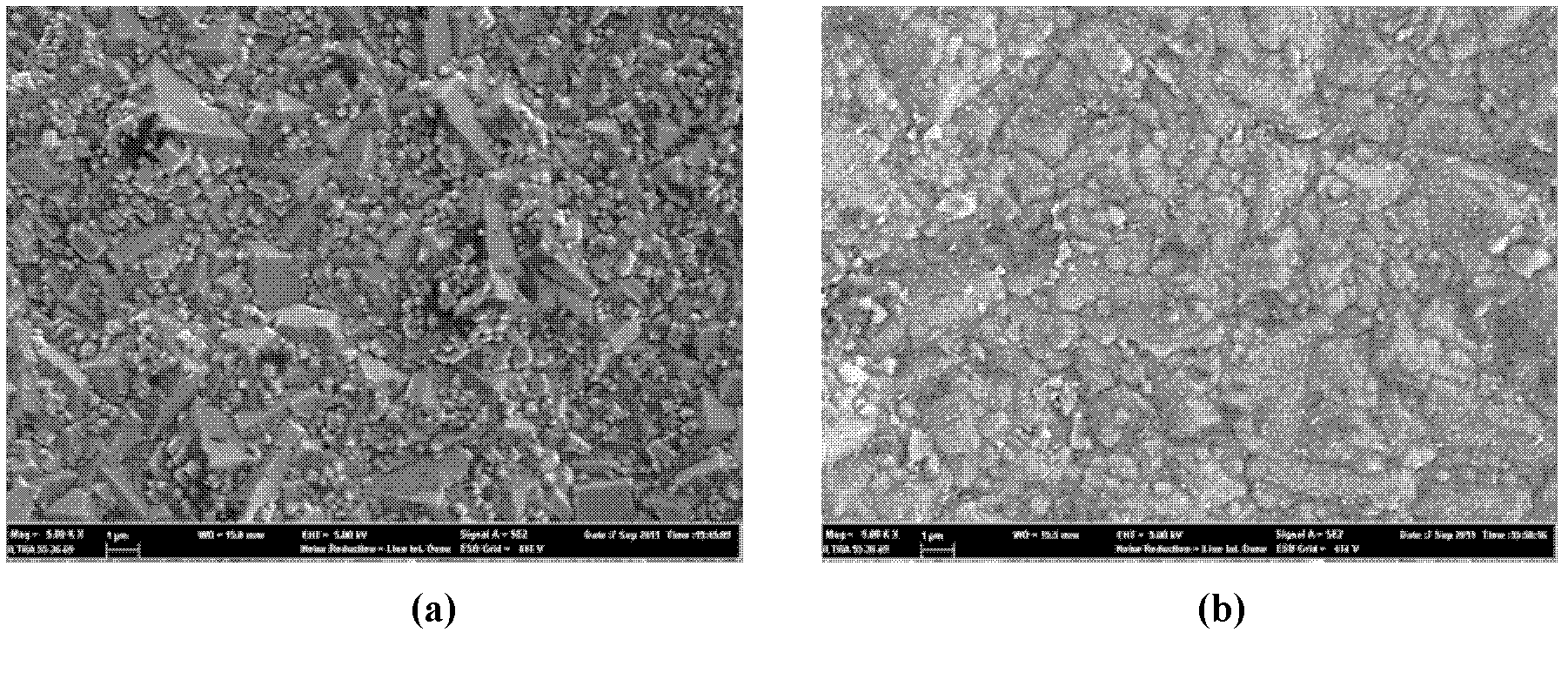

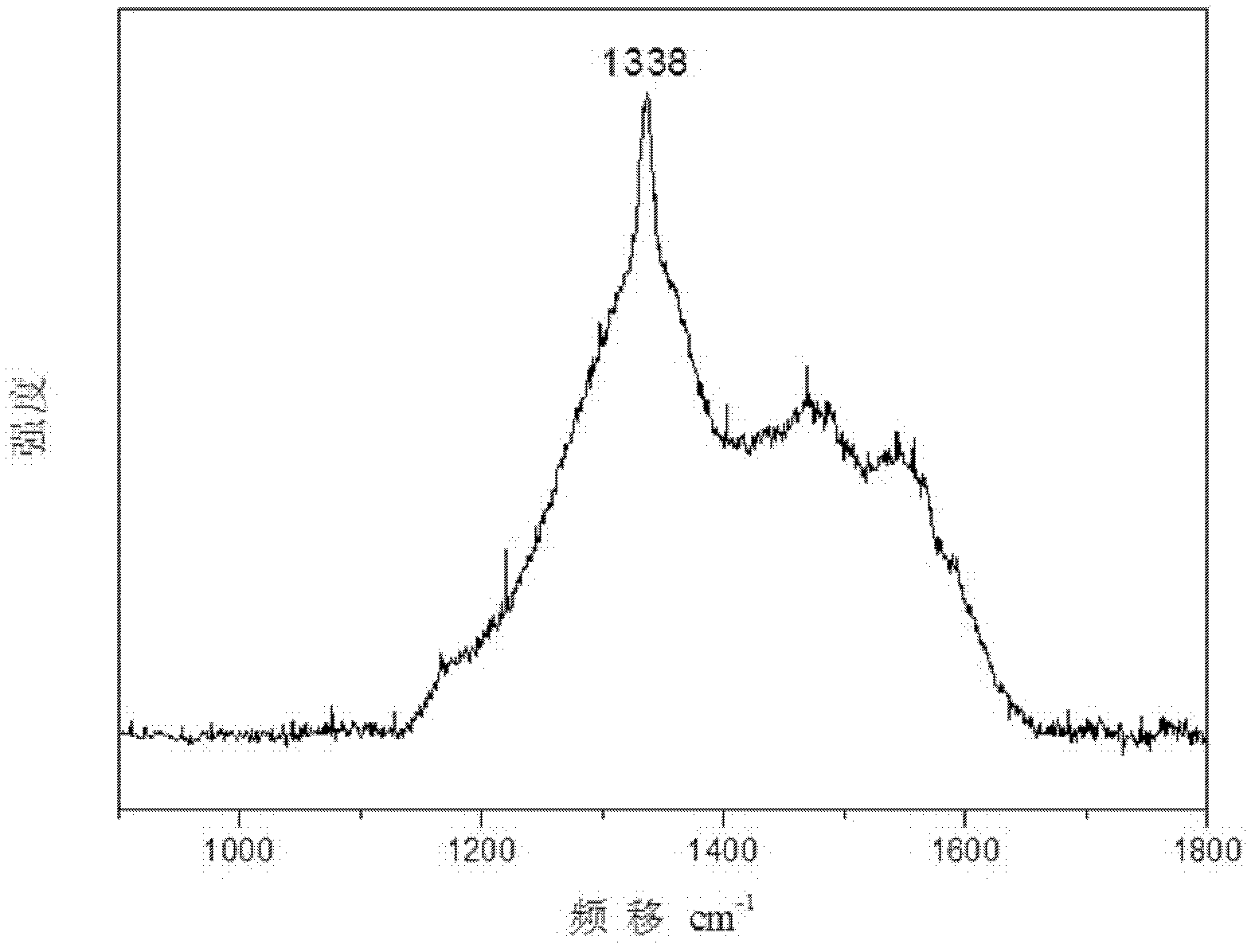

[0037] The substrate is a polished high-resistance silicon wafer at 3 o'clock. The pretreatment uses W1 diamond micropowder to grind the polished surface for 15 minutes. After washing with pure water, it is dried and placed on a rotating platform in the reaction chamber to start the deposition of CVD diamond film. There are six Φ6 parallel straight-drawn tantalum wires (hot wires) above the rotating platform, and the distance between the tantalum wires and the silicon wafer is 10 mm. The deposition process conditions of the diamond film are: the carbon source is acetone, tetraethoxysilane is dissolved in the acetone, wherein the Si / C atomic ratio is 1: 100, the reaction chamber pressure is 4.5KPa, and the total gas flow weighs 700 ml / min. The volume ratio of acetone / hydrogen is 1-2:100, and the temperature of the tantalum wire is about 2100°C. After 8 hours of deposition, an intrinsic diamond film with a thickness of 16 microns and an area of 3 o'clock is obtained. Compared ...

Embodiment 2

[0040] Take 10 Φ5mm cemented carbide (YG6) milling cutters, place the blades of the milling cutters in Murakami agent for ultrasonic corrosion, and the formula (weight ratio) of the corrosion solution is potassium ferricyanide: potassium hydroxide: water is 1: 1:10, the time is about 20 minutes, take it out and wash it with water, then put it in hydrochloric acid hydrogen peroxide solution (volume ratio 1:4) to corrode for 20-30 seconds, wash it with water, then put it in diamond micropowder (particle size 20 microns) ethanol Ultrasonic oscillation treatment in the suspension for 20 minutes, then wash and dry, insert 10 milling cutters evenly into the cooling socket and place them in the CVD reaction chamber to start the deposition of the CVD diamond film coating. The process parameters are: carbon source is acetone Mainly, tetraethoxysilane and trimethyl borate are dissolved at the same time, wherein the Si / C atomic ratio is 3:100, the B / C atomic ratio is 1:100, the reaction c...

Embodiment 3

[0043] Take 5 Φ15mm cemented carbide (YG6) milling cutters, place the blades of the milling cutters in Murakami agent for ultrasonic corrosion, and the formula (weight ratio) of the corrosion solution is potassium ferricyanide: potassium hydroxide: water is 1: 1:10, the time is about 20 minutes, take it out and wash it with water, then put it in sulfuric acid hydrogen peroxide solution (volume ratio 1:10) to corrode for 20-30 seconds, wash it with water, then put it in diamond micropowder (particle size 20 microns) ethanol Ultrasonic oscillation treatment in the suspension for 20 minutes, then wash and dry, insert 5 milling cutters evenly into the cooling socket and place them in the CVD reaction chamber to start the deposition of the CVD diamond film coating. The process parameters are: carbon source is acetone Mainly, dimethyldiethoxysilane, trimethyl borate and urea are dissolved at the same time, wherein the atomic ratio of Si / C is 0.1:100, the atomic ratio of B / C is 0.1:10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com