PIN Si-based film solar battery and manufacturing method thereof

A technology of solar cells and silicon-based thin films, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of industrialization of solar cells, and achieve the effects of reducing interface defects, increasing carrier mobility, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

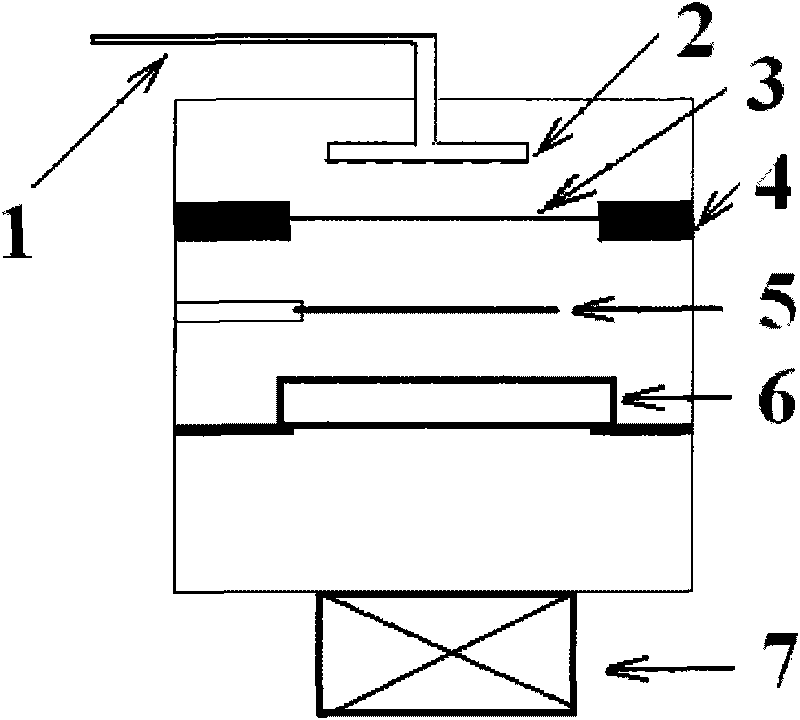

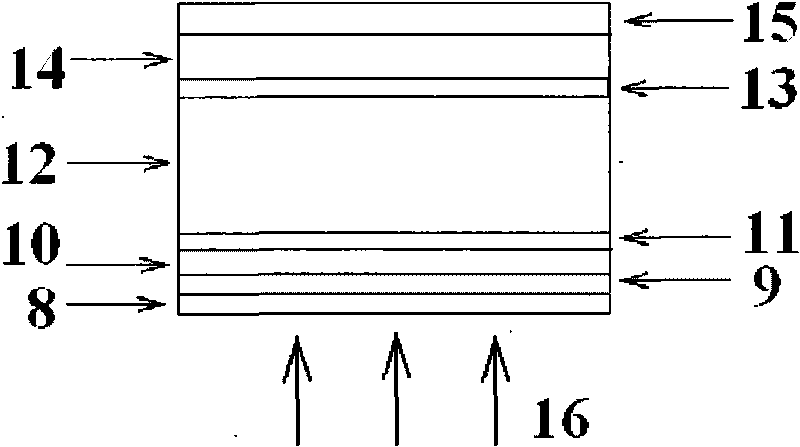

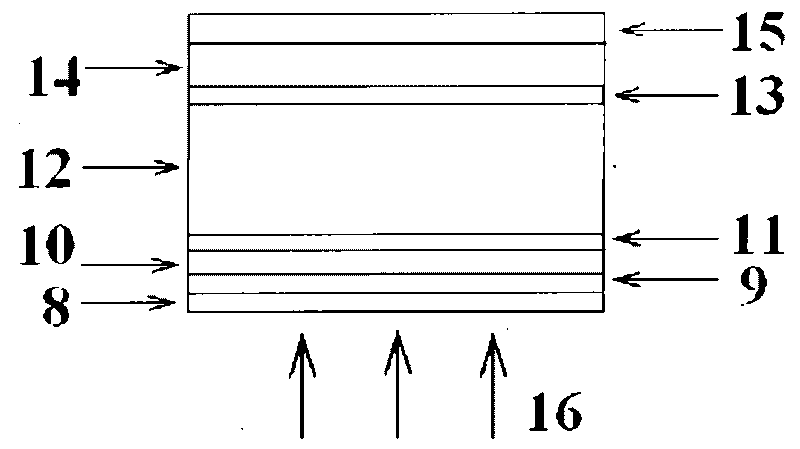

[0019] A silicon-based thin-film PIN junction solar cell, adopting hot filament chemical vapor deposition on a transparent conductive glass to successively deposit the P-layer, I-layer, dielectric passivation layer and the P-layer of the silicon-based thin-film solar cell core-PIN junction N-tier. Concrete preparation process is as follows:

[0020] 1. Put the cleaned transparent conductive film substrate into the chamber, raise the temperature, and evacuate the chamber to a suitable background vacuum value.

[0021] 2. When the substrate temperature and vacuum degree meet the requirements, grow the P-layer. The specific parameters are as follows:

[0022] Flow ratio: SiH 4 :B 2 h 6 =1:0.01, the dilution ratio is controlled at 91%, the air pressure is controlled at 2Pa, the substrate temperature is 250°C, the temperature of the hot wire is controlled at ~1900°C, the distance between the substrate and the hot wire is controlled at 5cm, and the film thickness is controlled a...

Embodiment 2

[0032] A silicon-based thin-film PIN junction solar cell, adopting hot filament chemical vapor deposition on a transparent conductive glass to successively deposit the P-layer, I-layer, dielectric passivation layer and the P-layer of the silicon-based thin-film solar cell core-PIN junction N-tier. Concrete preparation process is as follows:

[0033] 1. Put the cleaned transparent conductive film substrate into the chamber, raise the temperature, and evacuate the chamber to a suitable background vacuum value.

[0034] 2. When the substrate temperature and vacuum degree meet the requirements, grow the P-layer. The specific parameters are as follows:

[0035] Flow ratio: SiH 4 :B 2 h 6=1:0.01, the dilution ratio is controlled at 91%, the air pressure is controlled at 2Pa, the substrate temperature is 250°C, the temperature of the hot wire is controlled at ~1900°C, the distance between the substrate and the hot wire is controlled at 5cm, and the film thickness is controlled at...

Embodiment 3

[0045] A silicon-based thin-film PIN junction solar cell, adopting hot filament chemical vapor deposition on a transparent conductive glass to successively deposit the P-layer, I-layer, dielectric passivation layer and the P-layer of the silicon-based thin-film solar cell core-PIN junction N-tier. Concrete preparation process is as follows:

[0046] The preparation process of silicon-based thin-film PIN junction solar cells. The process steps are: use transparent conductive glass as the substrate, and grow the P-layer on it by hot wire chemical vapor deposition. The growth process is as follows: Flow ratio: SiH 4 :B 2 h 6 =1:0.01, the dilution ratio is controlled at 90%, the air pressure is controlled at 1Pa, the substrate temperature is 150°C, the temperature of the hot wire is controlled at 1800°C, the distance between the substrate and the hot wire is controlled at 3cm, and the film thickness is controlled at 10nm; A layer of silicon nitride dielectric material is grown ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Short circuit current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com