Preparation method for diamond coated mechanical seal ring

A technology of diamond coating and mechanical seal, applied in metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of short working life and achieve the effect of improving working life, shortening time and reducing wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

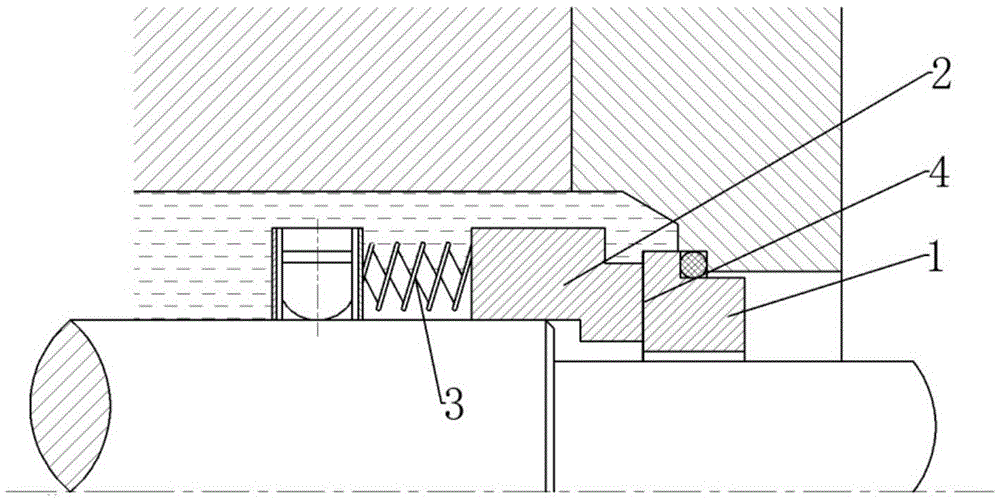

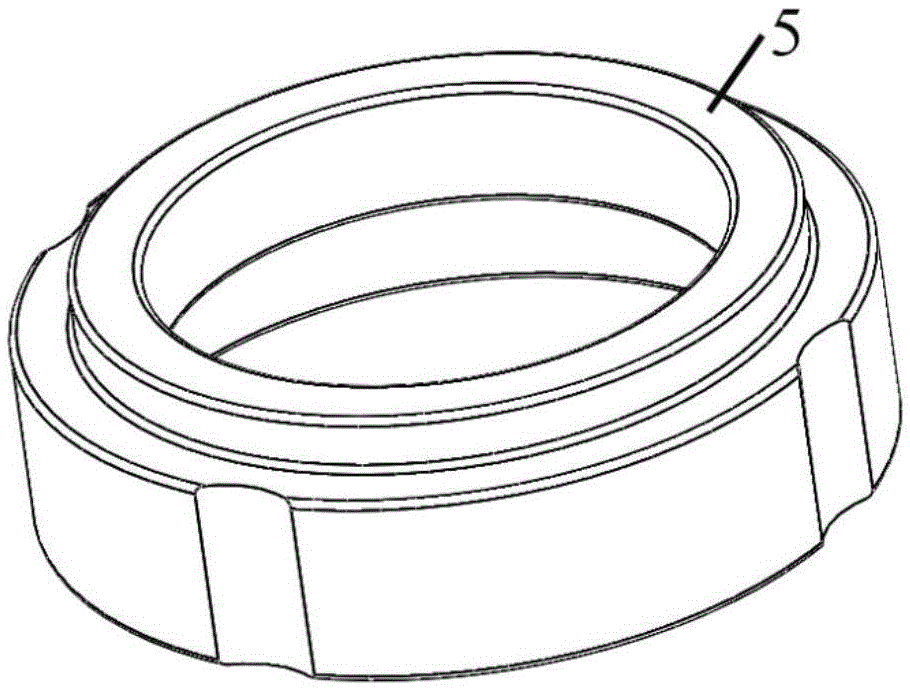

[0033] The mechanical seal ring in this embodiment is directly applied to the performance test of the standard 100-hour seal ring. The base material of the seal ring is silicon carbide, and the external dimensions are The working surface is ring-shaped, with an inner diameter of 40mm and an outer diameter of 45mm.

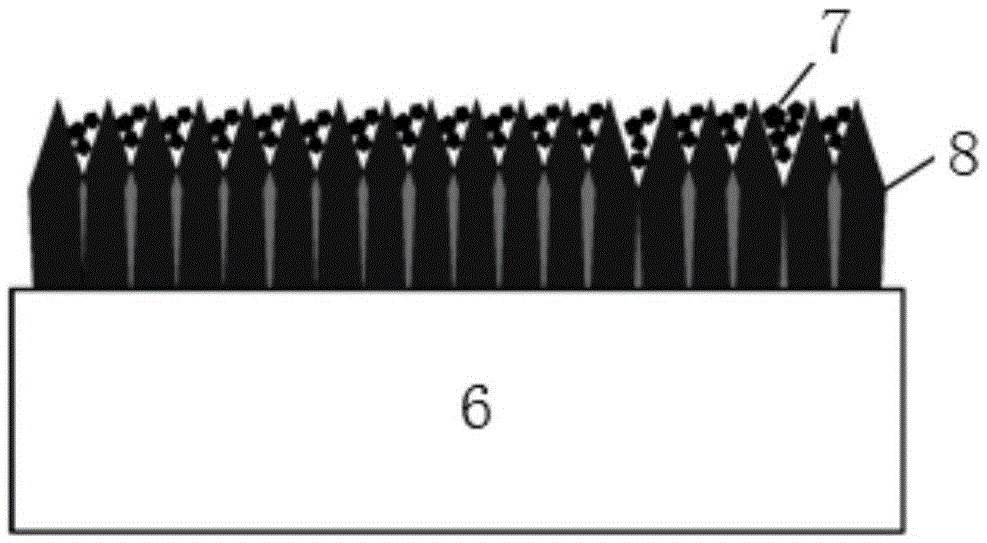

[0034] The steps for preparing the diamond-coated silicon carbide mechanical seal ring are as follows: use 10 μm thick diamond grinding fluid to ultrasonically roughen the working surface, and then use 1 μm diamond micropowder to mechanically grind and distribute the crystal of the seal ring. The diamond film was deposited on the surface of 15 silicon carbide mechanical seal rings simultaneously by means of 10 hot wires arranged in parallel. The deposition time of the micro-diamond film was 8 hours, and the deposition time of the nano-diamond film was 2 hours. Finally, use a plane polishing machine to level the surface of the diamond film, and the time for levelin...

Embodiment 2

[0037] The diamond-coated mechanical seal ring of this embodiment is applied to a high-pressure pump, the conveying medium is viscous cement slurry, the base material of the seal ring is silicon nitride, and the external dimensions are The working surface is ring-shaped, with an inner diameter of 30mm and an outer diameter of 35mm.

[0038] The specific preparation method of the sealing ring is as follows: first, the working surface of the sealing ring is roughened ultrasonically with 12 μm diamond grinding liquid, and the treatment time is 10 minutes; then, the sealing ring is ground and crystal-distributed with 2 micron diamond powder; finally, pure water and Acetone was used to clean the workpiece. The diamond film was deposited on the surface of 12 sealing rings simultaneously by means of parallel hot wire arrangement, and the distance between the hot wire and the deposition surface was 10 mm. The total power of the hot wire in the micro-diamond film deposition stage is ...

Embodiment 3

[0041] The diamond-coated mechanical seal ring of this embodiment is applied in the delivery pump of the purified terephthalic acid plant. The device contains a large amount of toxic, harmful, flammable, explosive and highly corrosive chemical raw materials, so the requirements for the airtightness of the device are very high. The base body of the mechanical seal ring for this application is YG6 cemented carbide, and its dimensions are The working surface is ring-shaped, with an inner diameter of 34mm and an outer diameter of 40mm. The specific steps for depositing a diamond film on the working surface of a traditional hard alloy mechanical seal ring are as follows: first, immerse the seal ring in Murakami solution for ultrasonic treatment for 30 minutes, then wash and dry the hard alloy substrate with Caro solution for 1 minute to remove the cobalt on the surface of the substrate Elements, followed by mechanical grinding and polishing with 8 μm diamond abrasive liquid and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com