Process for preparing diamond covering on sintered-carbide tool

A technology of diamond coating and cemented carbide, which is applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., and can solve the problems of low adhesion of diamond coating and complicated preparation process of coating transition layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Routine pretreatment of carbide tools to be diamond-coated:

[0020] 1. The ratio is KOH:K 3 [Fe(CN) 6 ]: H 2 O=1:1:10 (mass ratio) alkali solution roughens the surface of the cemented carbide substrate for 20 minutes.

[0021] 2. The ratio is H 2 SO 4 :H 2 o 2 =1:10 (volume ratio) acid solution corrodes the cemented carbide substrate for 2 minutes.

[0022] 3. Ultrasonically or manually grind the surface of the cemented carbide tool for 20 minutes with the alcohol suspension of diamond micropowder.

[0023] 4. Use alcohol solution to ultrasonically clean the surface of the cemented carbide tool for 5 minutes.

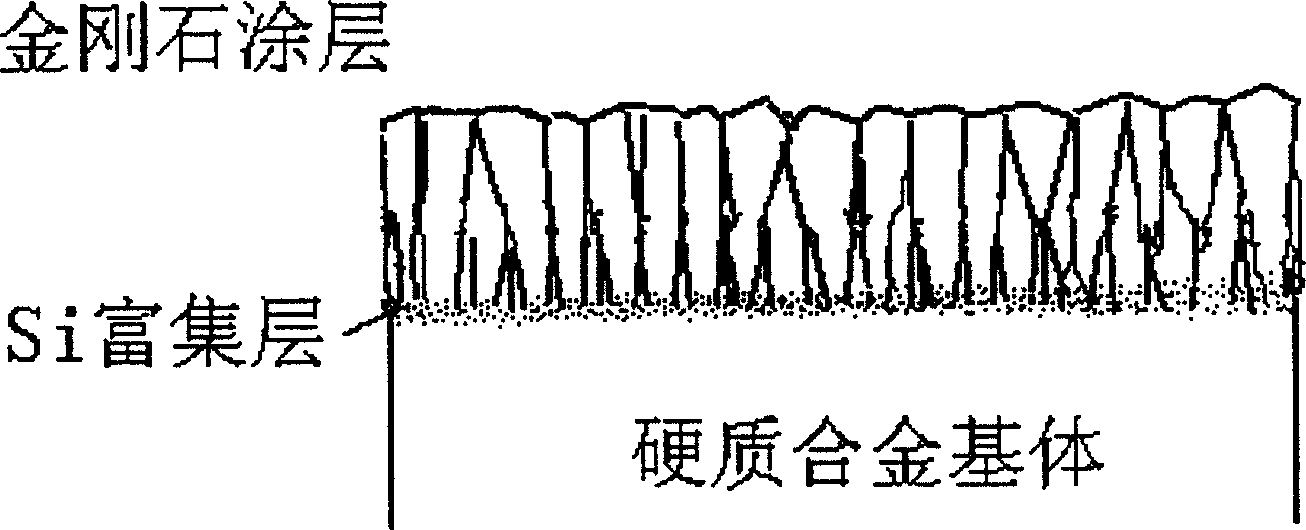

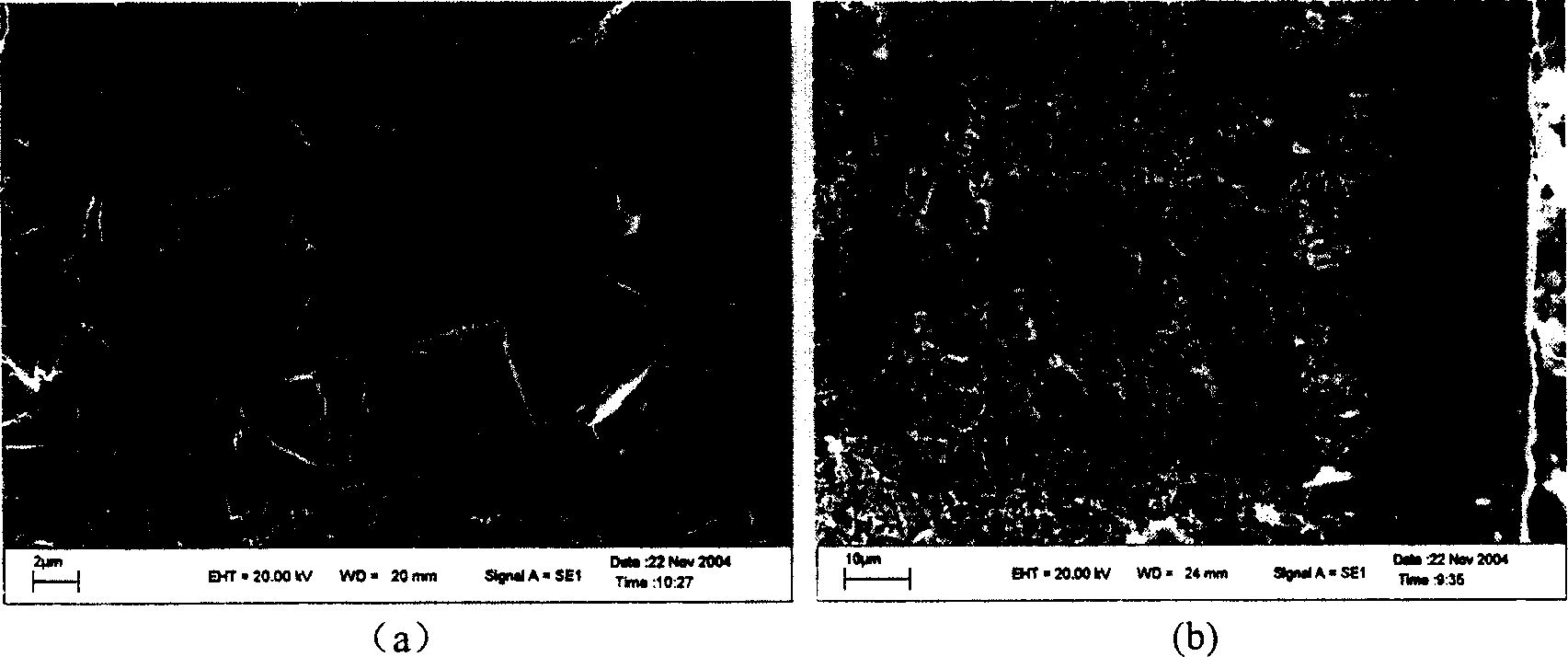

[0024] Thereafter, the desired diamond coating is prepared by microwave plasma chemical vapor deposition. During chemical vapor deposition, the raw gas includes H 2 、CH 4 and octamethylcyclotetrasiloxane. The purpose of using octamethylcyclotetrasiloxane as the feed gas for the chemical vapor deposition process is to use it to introduce silicon into ...

Embodiment 2

[0028] Carry out the same pretreatment as in Example 1 to the cemented carbide tool to be applied with diamond coating. Thereafter, the desired diamond coating was prepared using a DC arc plasma chemical vapor deposition method. During chemical vapor deposition, the raw gas includes H 2 、CH 4 and SiH 4 . Here, SiH 4 Plays the role of introducing silicon into the chemical vapor deposition system, H 2 、CH 4 Gas is the main reactive gas necessary to deposit the diamond phase.

[0029] The ratio of the mixed gas was adjusted to a ratio of hydrogen:carbon:silicon of 100:1.5:5, and the pressure was adjusted to 20 kPa. Under the action of plasma, H 2 、CH 4 and SiH 4 will be excited and decomposed, and a silicon-containing diamond coating is deposited on the cemented carbide tool heated to 900°C. At the later stage of the above deposition process, change the reaction gas to consist only of H 2 and CH 4 The reaction gas is formed and the deposition of the diamond coating i...

Embodiment 3

[0031] Carry out the same pretreatment as in Example 1 to the cemented carbide tool to be applied with diamond coating. Thereafter, using the hot wire CVD method, the desired diamond coating is prepared. During chemical vapor deposition, the raw gas includes H 2 、CH 4 and SiH 4 .

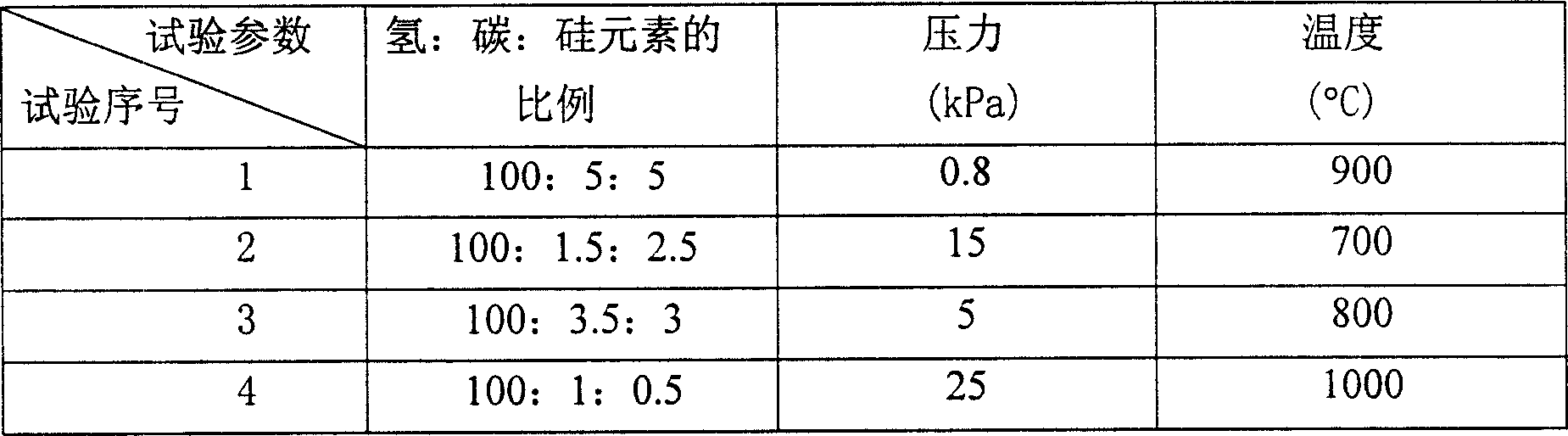

[0032] Adjust the ratio of hydrogen: carbon: silicon in the mixed gas, the pressure, and the temperature of the cemented carbide substrate to the range shown in Table 1.

[0033] Table 1 Deposition test parameters of diamond coating

[0034]

[0035] Under the experimental parameters in Table 1, a silicon-containing diamond coating was deposited on a cemented carbide tool. In the above deposition process, after 3 hours after the deposition process was started, the reaction gas was changed to only H 2 and CH 4 The reaction gas is formed to continue the deposition of the diamond coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com