Apparatus and method for nucleotion and deposition of diamond using hot-filament DC plasma

A technology of discharge plasma and hot filament, which is applied in chemical instruments and methods, crystal growth, transportation and packaging, etc., and can solve problems such as inability to extract ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Nucleation on Example 1 Smooth Mirror Quartz

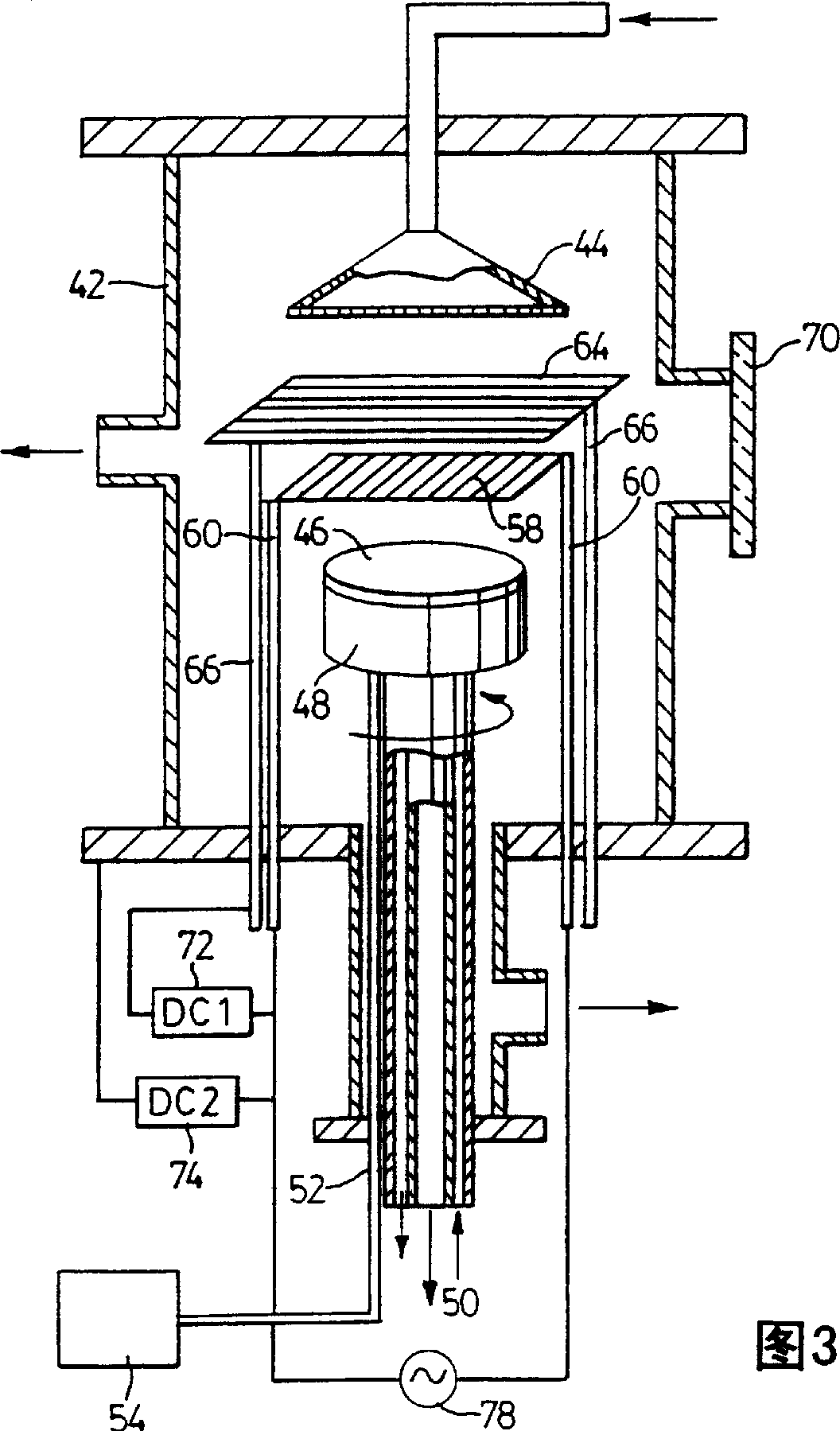

[0045] Using the apparatus shown in FIG. 3 , by applying a bias voltage of 89V to the filament group 58 and heating it to a temperature of about 2160°C, and applying a bias voltage of 200V to the grid 64, diamond formation can even be achieved on smooth mirror quartz. nuclear. The reactant gas mixture is methane / H 2 mixtures with respective flow rates of 6.5 standard cubic centimeters per minute (sccm) for methane and 300 sccm for hydrogen at a total pressure of 30 Torr. The nucleation process lasted about 10 minutes. However, the bias voltage on the filament set 58 is turned off and the bias voltage applied to the grid electrode 64 is adjusted to 120V to allow diamond growth. A faceted diamond film with good coherent and uniformity is obtained. Under the same growth conditions, but without the nucleation step, only shard-like diamonds of uneven thickness formed on the smooth specular quartz. Later...

Embodiment 2

[0046] Embodiment 2 Diamond Heteroepitaxial Growth on Silicon (see Figure 6)

[0047] Using the method and apparatus of FIG. 3, directionally crystallized diamond was grown on Si(100) of silicon pre-cleaned with HF solution, with a filament temperature of about 2200° C., a grid bias of 219 V and a filament bias of 130 V, to nucleate. The reactant gas mixture is methane / H 2 mixtures, each with a flow rate of 6 sccm for methane and 300 sccm for hydrogen, and a total pressure of 50 Torr. The nucleation time is about 10 minutes. Then a bias of OV is applied to the filament group to make the diamond grow. During this process, the gate bias is changed to 112V. Figure 6a The diamond (100) cubic crystal is clearly shown with the (100) plane aligned with the Si(100) and the diamond azimuthal plane [110] aligned with the Si[110] azimuthal plane. When diamond grows with a high nucleation density, a coherent film with diamond(100) / / Si(100), and diamond[110] / / Si[...

Embodiment 3

[0048] The rapid deposition of embodiment 3 diamond films

[0049] Utilize the apparatus of Fig. 3, make diamond coating growth 160 hours, reach 2.5mm thick, and 2 " diameter. The pressure of diamond growth is 30 Torr, and the bias voltage that grid electrode is applied is 45V with respect to filament group. Filament power density is about 170W / cm 2 , the plasma power density is 40W / cm 2 . The growth rate was 16 μm / hr. Both Raman and X-ray photoelectron spectroscopy indicated that the sample was pure diamond with no impurities (data not shown).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com